What is a Distributed Control System (DCS)? – Architecture, Working & Interview Guide

Published on July 15, 2024 | Category: introductionShare this Page:

A Distributed Control System (DCS) is an advanced, flexible, and fault-tolerant control platform designed to automate and supervise large-scale industrial processes. It plays a vital role in industries like oil and gas, power generation, pharmaceuticals, chemical processing, and water treatment, where process continuity and safety are paramount. Unlike traditional centralized systems, DCS distributes control functions to multiple intelligent controllers located throughout the plant, enhancing system stability, responsiveness, and scalability.

Each controller operates autonomously yet remains connected to a central operator interface via high-speed communication networks. This architecture allows operators to monitor and control processes in real-time while maintaining system integrity and minimizing downtime. Key components typically include engineering stations, Human-Machine Interfaces (HMI / SCADA), I/O modules, redundant processors, and data historians—all integrated into a unified platform.

Modern DCS solutions are designed with built-in redundancy and advanced diagnostics to detect, isolate, and recover from faults without disrupting operations. These systems also offer high levels of customization, modular expansion, and easy integration with enterprise resource planning (ERP) or manufacturing execution systems (MES).

In process control industries, the adoption of DCS improves productivity, ensures higher product quality, and reduces operating costs. Its ability to manage distributed field devices and seamlessly coordinate operations from multiple stations makes it the preferred choice for mission-critical applications where reliability, precision, and real-time control are essential.

Understanding Distributed Control System (DCS) – Definition & Industrial Use

A Distributed Control System (DCS) is a specialized computerized control platform used in industrial automation to manage, regulate, and monitor large-scale and geographically distributed processes. Unlike centralized systems, a DCS divides control logic among multiple local controllers spread across the plant area, enhancing system reliability, safety, and performance.

DCS systems are widely implemented in industries such as power generation, oil and gas, chemical manufacturing, mining, water treatment, and pharmaceuticals. These systems are essential where continuous or batch processing must be precisely coordinated with minimal human intervention.

Each controller within the DCS network communicates with field devices (like sensors and actuators) and operator workstations via high-speed, robust communication protocols. This decentralized structure ensures redundancy, fast response times, and real-time process visualization.

DCS Architecture Diagram – Controllers, Field Devices & HMI / SCADA

Full Form of DCS

The full form of DCS is Distributed Control System. It refers to a computerized control system used in industrial automation where control and monitoring functions are distributed throughout the plant instead of being centralized in one location.

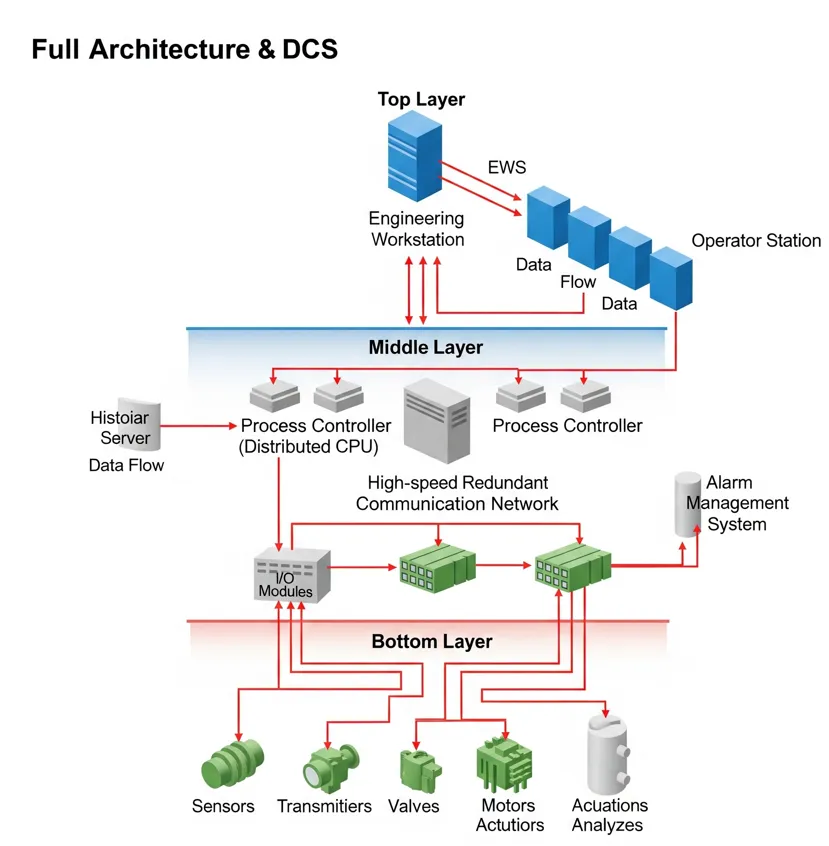

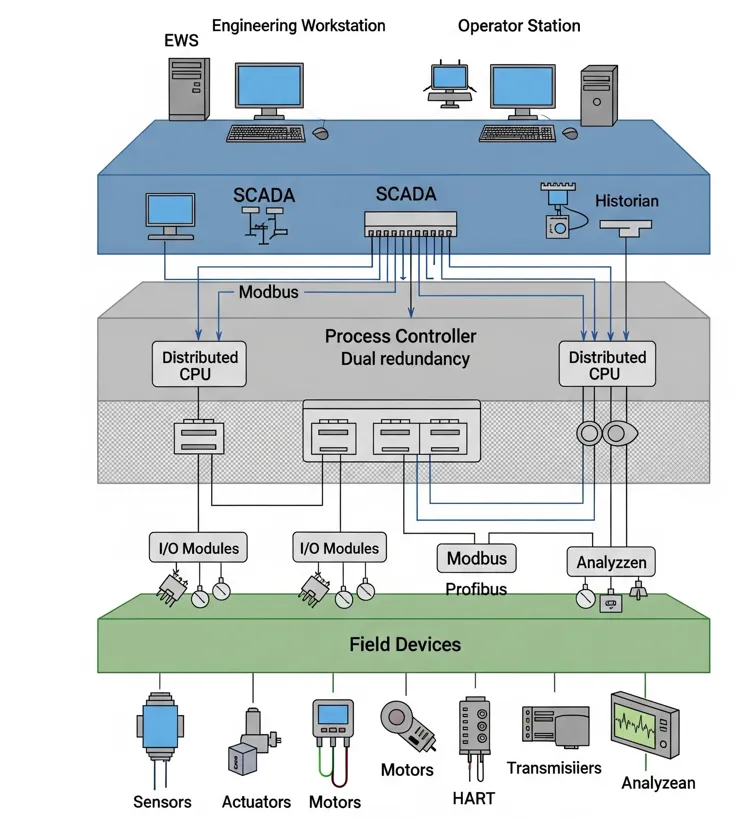

Architecture of Distributed Control System (DCS)

A modern Distributed Control System (DCS) is built on a layered and modular architecture, ensuring high availability, scalability, and fault tolerance. It distributes control functions across various components to maintain consistent process operations.

The main components of a DCS architecture include:

- Engineering Workstation (EWS): Used for system configuration, control logic programming, diagnostics, and maintenance.

- Operating Station : The graphical interface where operators monitor real-time data, acknowledge alarms, and control processes.

- Process Controllers: Distributed CPUs that execute control algorithms (like PID) and manage field device I/O. Each handles a specific plant area or unit.

- Communication Network: High-speed redundant network (Ethernet, Profibus, FOUNDATION Fieldbus, Modbus, etc.) that links all stations, controllers, and devices.

- Field Devices: Sensors, transmitters, actuators, valves, motors, and analyzers connected to I/O modules of controllers for data acquisition and actuation.

- Historian Server: Archives plant data for analysis, trending, and compliance reporting.

- Redundancy Modules: Backup systems (CPU, power, communication) to ensure uninterrupted control during failures.

- Alarm Management System: For alarm prioritization, routing, and logging across multiple process areas.

This layered architecture allows seamless communication between the control layer and field level, providing enhanced reliability, easier troubleshooting, and centralized supervisory control across distributed process areas.

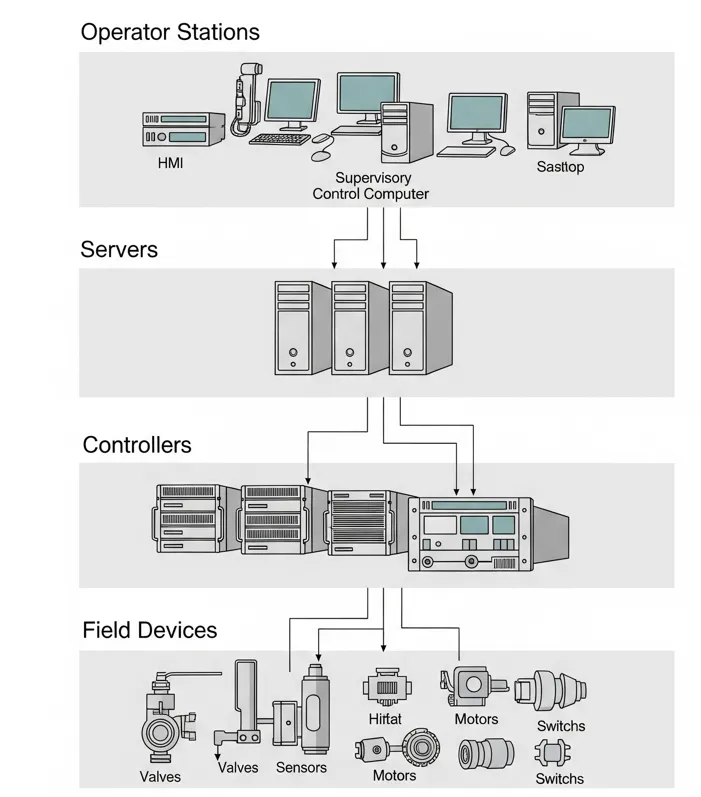

Explanation of the DCS Architecture Diagram

This image represents a layered architecture of a Distributed Control System (DCS) used in industrial automation. It shows how control functions are distributed from top-level supervision down to field-level actuation. Here's a breakdown of each layer from top to bottom:

1. Engineering Workstation (EWS) & Operator Station – Top Layer

- Engineering Workstation: Used for system configuration, control logic development, and diagnostics.

- Operator Station : Displays real-time process data, alarms, and allows manual operator intervention.

- These terminals are typically located in the control room and connect via Ethernet or fiber optic networks.

2. Process Controllers / CPUs – Middle Layer

- Controllers are distributed across plant zones and manage specific processes independently.

- They execute logic functions like PID control, sequencing, and interlocking.

- Communicate upward with HMI / SCADA and downward with field I/O modules.

- Often include redundant CPUs for fail-safe operations.

3. Communication Network

- All layers are linked via a high-speed, redundant industrial network.

- Common protocols include Profibus, Modbus, FOUNDATION Fieldbus, and Ethernet/IP.

- Often shown as red or dual communication lines in diagrams to represent redundancy.

4. I/O Modules

- Interface between controllers and field devices.

- Read analog/digital inputs such as temperature, pressure, flow.

- Send control signals to actuators like valves, relays, and motors.

5. Field Devices – Bottom Layer

- Include sensors, transmitters, actuators, valves, motors, analyzers, etc.

- Physically installed across the plant or field.

- Continuously send process data to the controller and respond to control outputs.

Important Features of Distributed Control System (DCS)

A Distributed Control System (DCS) is widely used in process industries due to its advanced capabilities in managing large-scale and continuous operations. Below are some of the key features that make DCS a preferred choice for industrial automation:

- 1. Distributed Control: Control tasks are divided across multiple controllers located near the process, reducing load on central systems and improving reliability.

- 2. Centralized Supervision: While control is distributed, monitoring and supervision are centralized through operator and engineering stations, providing complete plant visibility.

- 3. Modular Architecture: DCS systems are modular and scalable, allowing for easy expansion or modification of the control system as the plant grows or changes.

- 4. Redundancy: Most DCS systems include redundant CPUs, power supplies, and communication paths to ensure high availability and fault tolerance.

- 5. Real-Time Data Monitoring: Continuous data acquisition and real-time display of process variables enhance decision-making and response time.

- 6. Advanced Alarm Management: Supports prioritization, categorization, and routing of alarms to help operators respond efficiently to abnormal conditions.

- 7. Integration with Fieldbus Protocols: Supports communication standards such as Modbus, Profibus, HART, and FOUNDATION Fieldbus for seamless device connectivity.

- 8. Engineering and Maintenance Tools: Built-in software tools allow for efficient system configuration, loop tuning, diagnostics, and documentation.

- 9. Security and Access Control: DCS systems provide multi-level user access and cybersecurity features to protect against unauthorized changes or intrusions.

- 10. Historical Data and Trending: DCS includes data logging and historian functions for analyzing long-term trends, reports, and system optimization.

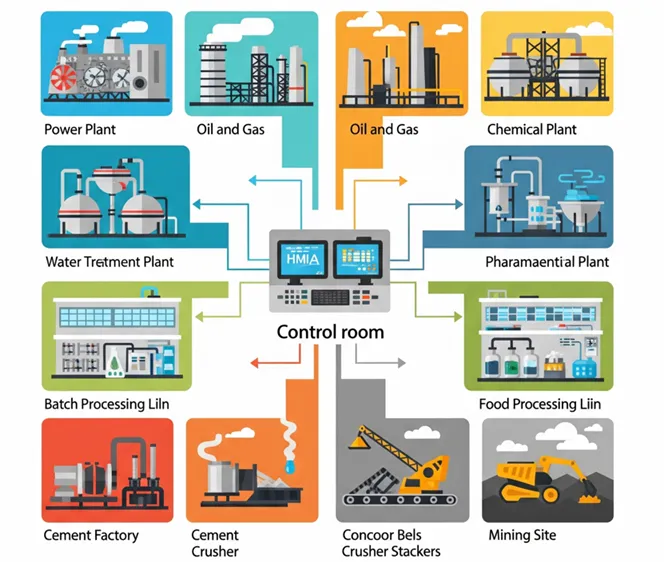

Applications of Distributed Control System (DCS)

Distributed Control Systems (DCS) are extensively used in industries where complex, continuous, or large-scale processes must be monitored and controlled with precision. Their ability to provide reliable, real-time automation makes them ideal for the following applications:

- 1. Power Generation Plants: For controlling boilers, turbines, and generators with real-time monitoring of electrical and thermal parameters.

- 2. Oil and Gas Industry: Used in refining, pipeline monitoring, offshore drilling platforms, and gas separation units.

- 3. Chemical and Petrochemical Plants: Essential for batch and continuous processing, reactor control, and safety interlocks.

- 4. Water and Wastewater Treatment: DCS manages filtration, chemical dosing, and pumping operations for consistent water quality.

- 5. Pharmaceutical Industry: Used for formulation control, cleanroom monitoring, and compliance with FDA/GMP standards.

- 6. Pulp and Paper Industry: DCS systems help automate paper machines, chemical recovery, and stock preparation processes.

- 7. Food and Beverage Industry: Enables consistent product quality, CIP (Clean-In-Place) systems, and packaging automation.

- 8. Cement and Mining Operations: Controls kilns, crushers, conveyors, and blending systems in rugged industrial environments.

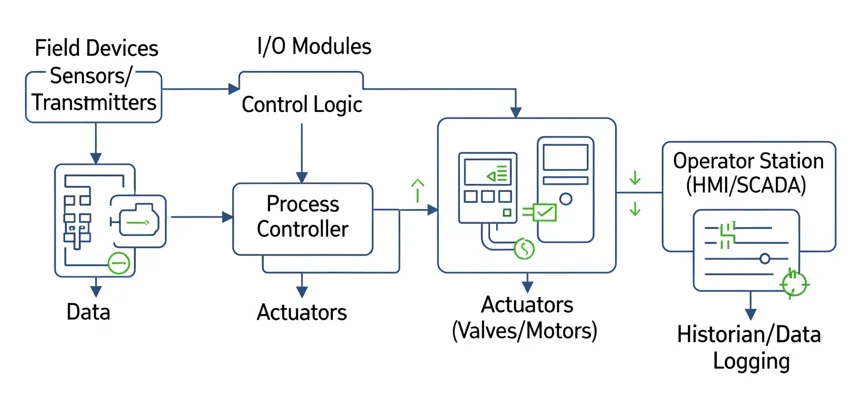

Step-by-Step Working of a Distributed Control System (DCS)

A Distributed Control System (DCS) performs process automation by monitoring input variables, processing control logic, and sending commands to field devices — all in a continuous, real-time cycle. Here's how it works step-by-step:

- Signal Acquisition from Field Devices: Sensors and transmitters (e.g., for temperature, pressure, level, flow) measure real-world parameters and send signals to the DCS.

- Signal Input to Controllers: These signals are received by I/O modules and sent to the appropriate process controller. Input types can be analog or digital, depending on the field device.

- Control Logic Execution: Distributed controllers process the inputs based on programmed control logic (e.g., PID loops, interlocks) to determine the necessary control action.

- Output Command to Actuators: Controllers send output signals to actuators such as control valves, motors, relays, and pumps to regulate the process.

- Real-Time Monitoring: Operator stations (HMI/SCADA) display process status, alarms, and trends. Operators can intervene if necessary.

- Data Logging and Diagnostics: DCS systems store operational data in historian servers and provide diagnostic tools for predictive maintenance and analytics.

How Does a DCS Work? – Operational Flow Chart Explained

A Distributed Control System (DCS) follows a structured sequence of operations, from sensing field conditions to processing control logic and adjusting outputs accordingly. The flowchart below represents the typical operation cycle of a DCS used in industrial automation systems.

DCS Operation Flow Chart

Flowchart Explanation:

- 1. Field Devices: Sensors and transmitters installed in the process area measure physical variables such as pressure, temperature, flow, and level.

- 2. Signal Conditioning / I/O Modules: These modules convert analog or digital sensor signals into a format readable by the controller (e.g., 4–20 mA to digital data).

- 3. Process Controllers: These distributed CPUs process input data using programmed logic (e.g., PID algorithms) and determine control actions based on setpoints.

- 4. Output Signals to Actuators: The controller sends appropriate output signals to devices like control valves, VFDs, and relays to adjust the process.

- 5. Operator Station (HMI): Displays real-time status of the process, alarms, and manual control options. Operators interact with the process through this interface.

- 6. Historian / SCADA Server: Stores time-stamped data for trending, reporting, and future analysis. Also integrates with enterprise-level software.

DCS Systems from Different Providers

Several global automation companies offer advanced Distributed Control Systems (DCS), each with unique features, architectures, and software environments. These systems are widely adopted across industries such as oil & gas, power, pharmaceuticals, and chemical processing based on reliability, integration, and scalability. Below are some of the most prominent DCS platforms from leading manufacturers:

- ABB – 800xA: A flexible, scalable, and integrated DCS platform known for extended automation and electrical control integration.

- Siemens – SIMATIC PCS 7: Offers modular engineering, seamless scalability, and powerful diagnostics based on the SIMATIC automation family.

- Honeywell – Experion PKS: Integrates DCS, SCADA, and safety systems with advanced process control and a unified operator interface.

- Emerson – DeltaV: Widely used in life sciences and process industries; features intuitive configuration and embedded advanced control strategies.

- Yokogawa – CENTUM VP: Known for high availability, deterministic control, and long lifecycle support in mission-critical applications.

- Schneider Electric – EcoStruxure Foxboro DCS: Offers open integration, high-performance control, and lifecycle digital twin support.

- Rockwell Automation – PlantPAx: A modern DCS solution based on PLC platforms with unified architecture for hybrid and process industries.

- GE – Proficy Process Systems: Provides flexible, scalable process automation integrated with GE’s digital industrial software suite.

Each DCS platform is suited to different industry requirements, project scales, and integration needs. Selection typically depends on process complexity, existing infrastructure, vendor support, and long-term maintenance strategy.

Difference Between DCS and SCADA

While both Distributed Control Systems (DCS) and Supervisory Control and Data Acquisition (SCADA) systems are used for industrial process control, they serve different roles and are suited for different types of operations. Here's a side-by-side comparison:

| Feature | DCS | SCADA |

|---|---|---|

| Architecture | Hierarchical and localized control system | Centralized monitoring system over a wide area |

| Application Type | Continuous, complex process industries (e.g., refineries, power plants) | Distributed geographical systems (e.g., water distribution, oil pipelines) |

| Real-Time Control | Direct real-time control with local controllers | Supervisory control; actual control handled by PLCs or RTUs |

| Operator Interface | Integrated with system (HMI + Control) | Primarily for data monitoring, alarms, and remote control |

| Network Dependency | Less dependent (local control continues even with network failure) | Highly dependent on communication network |

| Redundancy | High (built-in redundancy for reliability) | Varies; may not have full system redundancy |

Difference Between DCS and PLC

Both Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC) are used for industrial automation, but they differ significantly in architecture, application scope, and performance. Here's a detailed comparison:

| Feature | DCS | PLC |

|---|---|---|

| Control Scope | Process-level control for continuous or batch operations | Machine-level control for discrete events and sequences |

| Architecture | Distributed and integrated with HMI/SCADA | Modular and centralized or semi-distributed |

| Programming | Function blocks, SFC, graphical programming | Ladder logic, structured text, instruction list |

| Scalability | Highly scalable for plant-wide control | Good for small to medium systems; limited scalability for large plants |

| Cost | Higher initial cost; optimized for process reliability | Lower cost; flexible and easy to deploy |

| Redundancy | In-built redundancy in controllers, networks, and power | Redundancy available but often added externally |

History of Distributed Control System (DCS)

The concept of Distributed Control Systems (DCS) emerged as industrial automation evolved to manage increasingly complex and large-scale processes. The need for reliability, modularity, and real-time control drove the development of DCS technology. Below is a timeline outlining the major milestones in the evolution of DCS:

- 1970s – Invention of DCS: Traditional centralized control systems faced performance limitations in large plants. To overcome this, manufacturers like Honeywell and Yokogawa introduced the first commercial DCS systems, offering distributed processing power and modular control.

- 1980s – Standardization and Expansion: DCS systems became more widely adopted in process industries like oil & gas, petrochemicals, and power generation. Vendors introduced standardized communication protocols and better Human-Machine Interfaces (HMI).

- 1990s – Integration with Digital Networks: Ethernet, Foundation Fieldbus, and Profibus became common. DCS systems started integrating with intelligent field devices and offered higher-speed communication, diagnostics, and better redundancy features.

- 2000s – Web-based Tools and SCADA Integration: Modern DCS platforms began offering web interfaces, centralized data historians, and tighter integration with SCADA and ERP/MES systems for plant-wide visibility.

- 2010s–Present – Smart DCS and IIoT Integration: Today’s DCS platforms support Industrial IoT (IIoT), advanced analytics, cybersecurity, and cloud connectivity. They enable real-time decision-making and seamless integration with enterprise systems.