What is a Relay? Working Principle, Types, and Applications

Published on July 16, 2024 | Category: introductionShare this Page:

A relay is an electrically operated switch that uses an input signal (voltage or current) applied to a coil to open or close contacts. Most high-end industrial applications use relays for efficient and reliable operation. Relays function as simple switches, operated both electrically and mechanically.

A typical relay consists of an electromagnet and a set of contacts. The switching mechanism is driven by the electromagnet when energized. However, relays can also operate on other principles depending on their specific applications.

In general, the term 'relay' refers to a device that provides an electrical connection between two or more points in response to a control signal. Many relays use an electromagnet to mechanically operate the switching mechanism, but other types based on different technologies also exist.

To summarize, a relay is a simple electromechanical device used to control electrical circuits by opening and closing contacts in response to an external signal.

This page provides a detailed and beginner-friendly explanation of what a relay is, its working principle, internal components, and different types of relays used in electrical and industrial systems. Whether you're a student, technician, or engineering professional, this guide will help you understand how relays function and where they are used.

In this article, you will learn:

- What is a relay and how it works

- Key components of a relay (electromagnet, contacts, coil)

- Different types of relays like electromagnetic, solid-state, thermal, and reed relays

- Relay symbols and wiring diagrams

- Common applications of relays in automation and protection systems

- Advantages and disadvantages of using relays

- Interview-based insights and practical examples

This page is part of our Electrical Engineering Basics Series designed to help learners grasp essential components used in automation, control panels, and electrical systems.

What is Relay

A relay is an electrically operated switch that uses a small electrical signal to control the opening or closing of one or more sets of contacts in another circuit. It works by energizing an internal electromagnet, which moves a mechanical armature to change the state of the contact(s). This allows a low-power control circuit to safely operate high-voltage or high-current devices.

Relays are widely used in electrical control systems, automation, and protection applications to provide isolation, logic control, and remote switching functions.

Example:

Consider a case where a 12V DC signal is used to control a 230V AC lamp. A relay is placed between the low-voltage control circuit and the high-voltage lamp circuit. When the 12V control signal energizes the relay coil, the magnetic field closes the contact, allowing 230V to flow and turn on the lamp. When the control signal is turned off, the contact opens, and the lamp is switched off. This setup ensures that the high-voltage circuit is safely controlled without direct contact.

What Are the Different Types of Relays? Explained with Examples

Relays are classified based on their design, operating principle, and application. Below are the most common types of relays with a short description of each:

- 1. Electromagnetic Relay: Operates using an electromagnetic coil to open or close contacts. Widely used in control panels, industrial machines, and switching applications.

- 2. Solid State Relay (SSR): Uses semiconductor devices instead of mechanical contacts. It offers faster switching, longer life, and is suitable for silent operation in automation systems.

- 3. Thermal Relay: Works on the principle of heat generated by excessive current. Commonly used for overload protection in motors and electrical equipment.

- 4. Reed Relay: Consists of reed contacts enclosed in a glass tube, operated by a magnetic field. It is compact and used in low-current applications and signal switching.

- 5. Hybrid Relay: Combines features of electromagnetic and solid-state relays. It provides high-speed switching with physical isolation and durability.

- 6. Latching Relay: Remains in its last state even after the control signal is removed. It is energy-efficient and useful in memory-based circuits or toggle operations.

- 7. Differential Relay: Detects differences in current between two points and is mainly used for protection in transformers, generators, and motors.

- 8. Polarized Relay: Uses a permanent magnet along with the coil to enhance direction-sensitive operation. Often used in communication equipment.

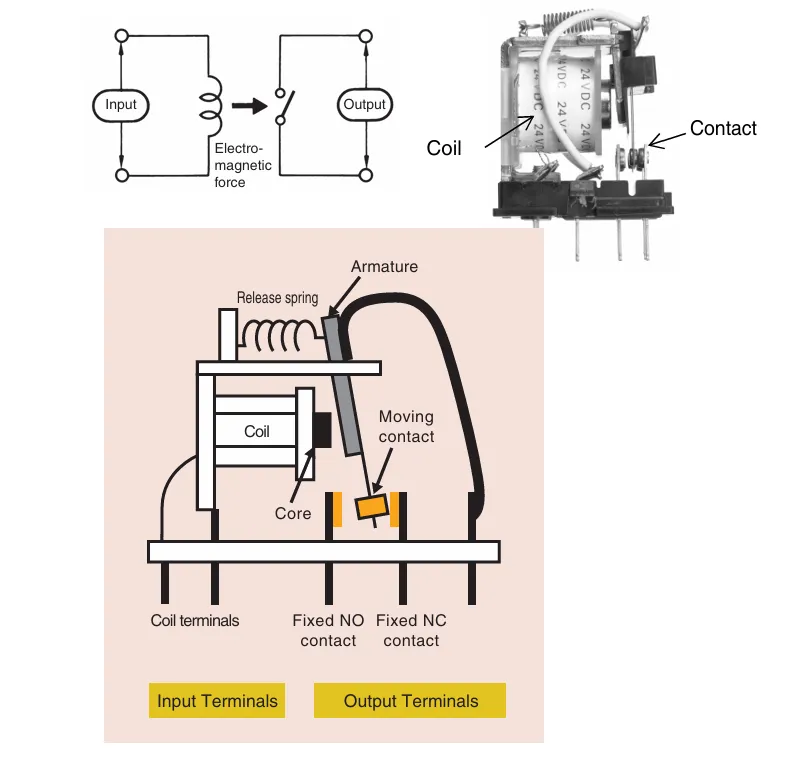

What is an Electromagnetic Relay?

An electromagnetic relay is a type of relay that uses an electromagnet to mechanically operate a switch. It allows a low-power electrical signal to control a high-power circuit, providing electrical isolation and remote switching in control systems. This type of relay is the most common form of electromechanical relay used in industrial and automation systems.

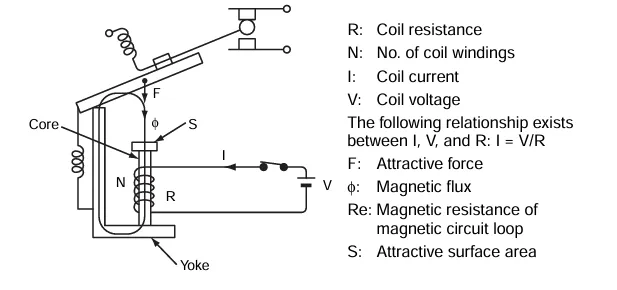

Parts and Components of an Electromagnetic Relay

The major parts of an electromagnetic relay include:

- Coil: A wire wound into a coil that generates a magnetic field when current flows through it.

- Core: A soft iron core inside the coil that enhances magnetic flux.

- Armature: A movable iron piece that is pulled toward the core when the coil is energized.

- Yoke: A fixed iron piece that forms the magnetic circuit along with the armature.

- Spring: A spring that returns the armature to its original position when the coil is de-energized.

- Contacts: Electrical points (Normally Open - NO and Normally Closed - NC) that open or close the circuit.

Working Principle of Electromagnetic Relay

When an electric current flows through the coil (primary circuit), it generates a magnetic field around the iron core. This magnetic field attracts the armature towards the core, overcoming the spring force. As the armature moves, it either closes the Normally Open (NO) contact or opens the Normally Closed (NC) contact.

When the current to the coil is turned off, the magnetic field collapses, and the spring pulls the armature back to its original position, resetting the contacts.

- In a Normally Open (NO) contact: The circuit closes only when the relay is energized.

- In a Normally Closed (NC) contact: The circuit is broken when the relay is energized.

- Double Throw (DT) or Changeover: The relay switches between two circuits using a common terminal.

Applications of Electromagnetic Relay

- Switching motors, lights, or heaters in control panels

- Overload and fault protection in electrical systems

- Used in timers, alarms, and safety interlocks

- Used in PLC-based industrial automation

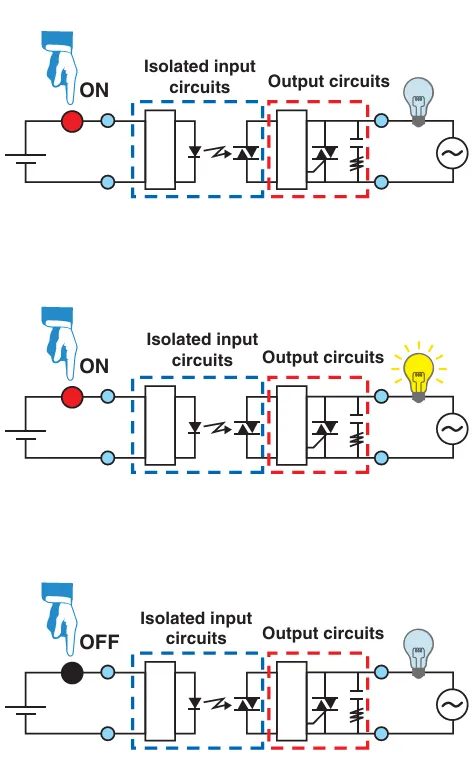

What is a Solid State Relay (SSR)?

A Solid State Relay (SSR) is a type of relay that uses semiconductor devices to perform switching without any moving parts. Unlike an electromagnetic relay, which uses mechanical contacts operated by a magnetic coil, SSRs switch ON/OFF electronically using components like thyristors, triacs, transistors, and diodes.

Key Features of Solid State Relays:

- No moving parts – silent and wear-free operation

- High-speed switching and longer life cycle

- Vibration-resistant and suitable for harsh environments

- Used for switching AC or DC loads electronically

Is a Solid State Relay the Same as an Electromagnetic Relay?

While both types of relays serve the same function — to switch a circuit ON or OFF — the key difference lies in the switching mechanism:

- Electromagnetic Relay: Uses mechanical contacts moved by a coil (physical movement)

- Solid State Relay: Uses electronic circuits and semiconductors (no movement)

SSRs are preferred in applications where silent, fast, and frequent switching is required.

Working Principle of a Solid State Relay (Step-by-Step)

- Input Signal: A switch or control signal (e.g., 5V or 24V) is turned ON.

- Photocoupler Activation: Current flows into the input circuit and activates an internal photocoupler.

- Trigger Circuit: The photocoupler sends a signal to the trigger circuit in the output stage.

- Switching Element Turns ON: A TRIAC or thyristor in the output section turns ON.

- Load Current Flows: The load (e.g., a lamp or motor) receives power and turns ON.

- Input Signal Turns OFF: The control signal is deactivated.

- Switching Element Turns OFF: The photocoupler and trigger circuit deactivate, turning the output OFF and stopping current to the load.

What is a Thermal Relay?

A Thermal Relay is a protective electrical device that operates based on the heat generated by excessive current. It is commonly used to protect motors and other equipment from overload conditions.

Working Principle:

When too much current flows through the relay, a bimetallic strip inside the relay heats up and bends. This bending movement triggers the relay’s contacts to open, stopping the power supply and protecting the load (e.g., a motor).

Common Applications:

- Overload protection for electric motors

- Starter circuits in industrial panels

- Backup protection for circuit breakers

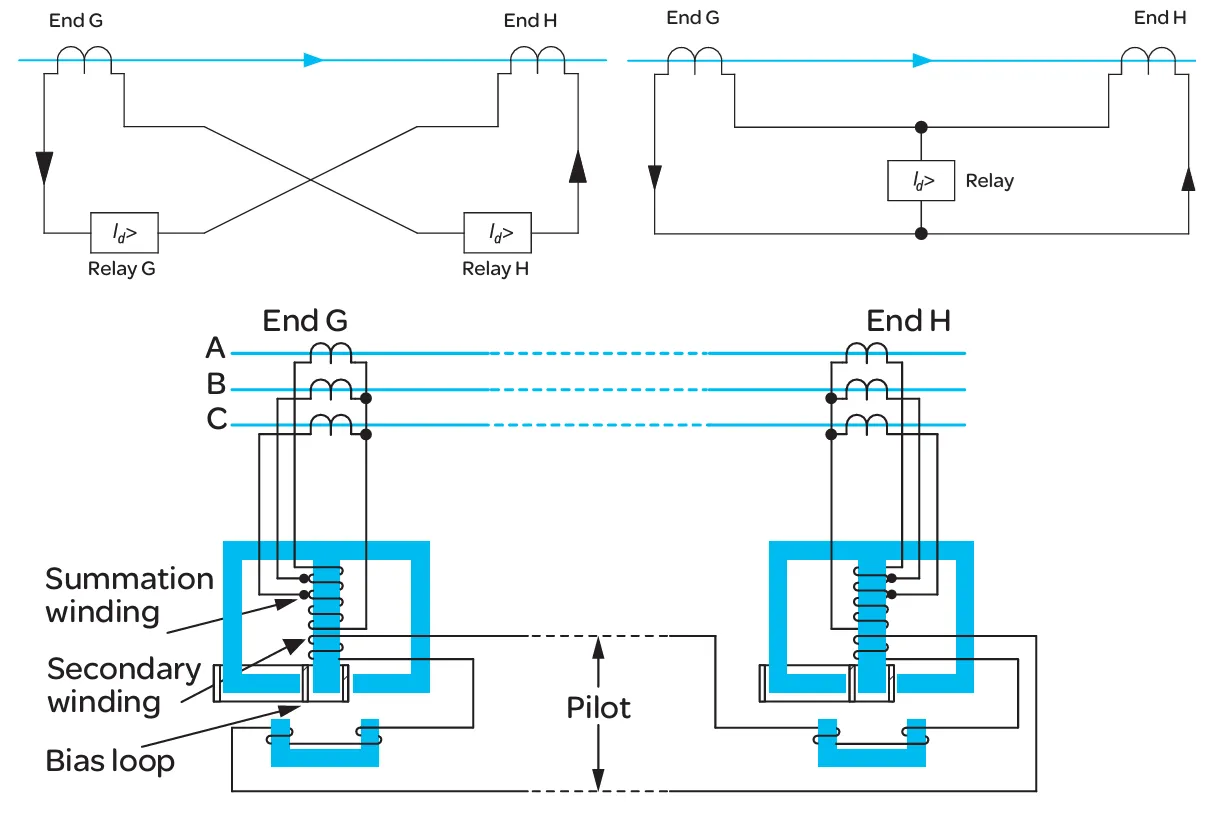

What is a Differential Relay?

A Differential Relay protects equipment by comparing the current entering and leaving a protected section and operates if there is a mismatch.

Working Principle:

It calculates the difference between two current transformers (CTs). If the difference exceeds a set threshold (indicating a fault), it trips the breaker.

Common Applications:

- Transformer protection

- Generator and motor protection

- Busbar fault detection

What is a Polarized Relay?

A Polarized Relay uses both an electromagnet and a permanent magnet to operate, making it sensitive to current direction.

Working Principle:

The direction of coil current determines whether the armature is attracted or repelled. This allows it to respond to polarity-sensitive signals.

Common Applications:

- Telecommunication circuits

- Direction-based relay logic

- Signaling and data systems

What is a Non-Polarized Relay?

A Non-Polarized Relay is a type of electromagnetic relay that can operate regardless of the direction of current flow through its coil. Unlike polarized relays, it does not depend on current polarity.

Working Principle:

When voltage is applied to the coil, it generates a magnetic field that attracts the armature and changes the contact state. Since polarity doesn’t matter, it works with both AC and DC control signals (depending on the design).

Common Applications:

- General-purpose switching circuits

- AC and DC logic-based control panels

- Relay logic systems without polarity requirements

What is a Reed Relay?

A Reed Relay is a type of relay that uses a magnetic field to operate reed contacts sealed inside a glass tube. It is compact and highly sensitive.

Working Principle:

When the coil is energized, it generates a magnetic field that closes the reed contacts inside the sealed tube, completing the circuit.

Common Applications:

- Signal switching in telecommunication devices

- High-speed and low-current switching

- Measurement and control systems

What is a Hybrid Relay?

A Hybrid Relay combines both electromechanical and solid-state components to offer the benefits of both technologies in a single device.

Working Principle:

A solid-state circuit handles initial switching, while mechanical contacts manage steady-state current. This improves switching speed and extends relay life.

Common Applications:

- Industrial control systems with frequent switching

- Automated power switching applications

- UPS and inverter protection circuits

What is a Latching Relay?

A Latching Relay maintains its last contact position even after the control power is removed. It is also called a bistable relay.

Working Principle:

Once triggered, the relay stays latched in its ON or OFF state using magnetic or mechanical locking, without continuous coil energization.

Common Applications:

- Memory and toggle functions in control systems

- Energy-saving circuits

- Remote switching and automation