Top VFD Interview Questions and Expert Answers

Published on Aug05, 2024 | Category: VFD InterviewYou can explore the most commonly asked VFD interview questions, accompanied by detailed expert answers to help you grasp key concepts and effectively demonstrate your knowledge. Whether you’re a seasoned professional or new to the field, our resource is designed to support your success by covering essential topics, technical details, and practical insights.

1. What is vfd?

VFD is "variable frequency drive", which are used to control speed of a motor by varying frequency of input power.A Variable Frequency Drive (VFD) is a type of motor starter or controller that drives an electric motor by varying the frequency and voltage of its power supply. VFDs also have the capability to control ramp-up and ramp-down of the motor during start or stop, respectively. Other names for a VFD are variable speed drive, adjustable speed drive, adjustable frequency drive, AC drive.

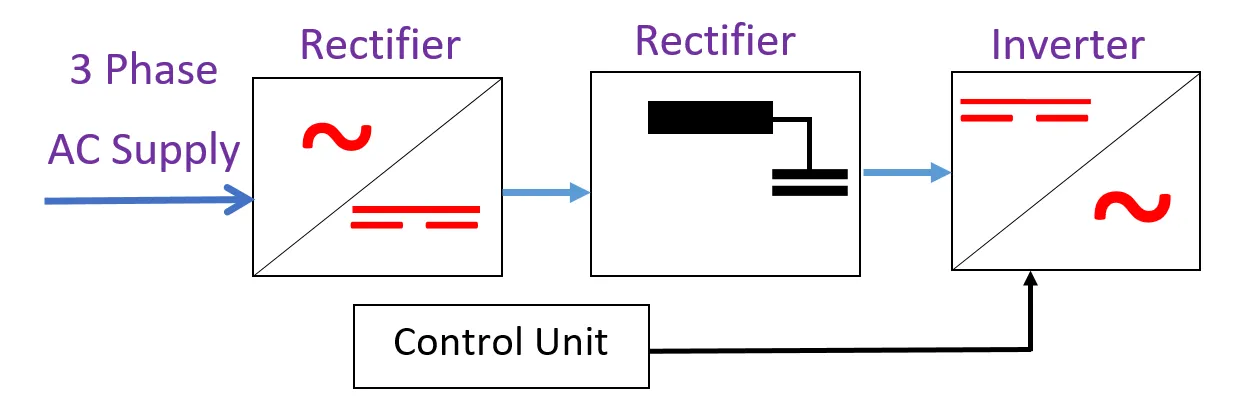

2. Draw a basic block diagram of vfd

3. explain control unit in vfd?

This section is the controlling unit responsible for controlling the switching operation, output frequency, output power. It is integrated with the user interface and sensors to acquire the necessary data. It also monitors fault conditions. The control unit consists of an embedded microprocessor programmed for controlling the rectifier and inverter section. It can react in microseconds in case of any fault conditions. The feedback data from the speed sensor is used to monitor the speed as well as adjust it accordingly to the need.

4. What is motor starter?

motor starter are used for starting an induction motor.The motor starters reduce the starting current so that the motor can start safely without any damage.

5. What is Inrush Current?

An induction motor consume higher current during starting because of low winding resistance. This higher current is known as inrush current.

6. What is Difference between vfd and contactor?

Soft starters and variable frequency drive (VFD) are different types of motor starters, both starters uses semiconductor components. Both have following difference

| Soft Starter | VFD |

|---|---|

| A semi-conductor-based motor starter, which starts and stops an induction motor well. | semi-conductor-based motor starters which start and stop the induction motor also vary the motor’s speed. |

| At full speed, the soft starter is bypassed by a contactor. | It operates continuously throughout the whole operation of the motor. |

| It can change the supply voltage only. | It can change the supply voltage and frequency. |

| Soft starters don’t need additional filters. | VFDs require fillers because of harmonics injection in the line. |

| Used for constant motor speed application. | a VFD can control both the voltage and the frequency applied to an electric motor. |

| Soft starters are useful when motors drive large loads that require a high current and torque to start rotating. | VFD used when motors need speed control while operating. |

| It is cheaper than VFD | VFDs are pretty expensive. |

7. What is basic principle of vfd?

A VFD have three basic section a rectifier, a DC bus, and an inverter.rectifier converts the input AC supply into DC. The DC bus stores and filters this DC power. Inverter then converts the DC power back to AC with the desired frequency and voltage.

8. Which type of modulation used in vfd?

Pulse Width Modulation (PWM): Most modern VFDs use Pulse Width Modulation (PWM) to create a variable output voltage and frequency. PWM works by switching the DC voltage on and off at a high frequency, varying the width of the pulses to control the average voltage sent to the motor. This method provides a smooth and efficient control of the motor speed.

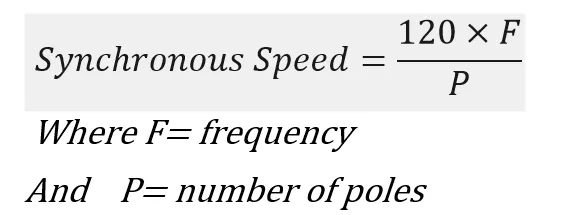

9. What is Synchronous Speed (Ns) ?

The Synchronous Speed (Ns)of an AC induction motor depends upon, The number of motor poles and The frequency of the applied power. formula for Synchronous Speed (Ns) is

10. Why VFD prefferd for speed control?

- Motor Protection :VFD's have built-in protection features such as overload protection, overvoltage protection, and thermal protection.

- Compatibility with Automation Systems: VFDs can be easily integrated with modern automation and control systems.

- Regenerative Braking: Some VFDs offer regenerative braking, which allows the energy generated during braking to be fed back into the power supply.

- Lower Starting Current: VFDs reduce the inrush current associated with motor startup, which can be several times higher than the running current.

- Energy Efficiency: VFDs adjust the motor speed to match the load requirements, which can result in significant energy savings.

- Precise Speed Control: VFDs offer precise control over motor speed, which is crucial for processes that require variable speeds.

- Smooth Start and Stop: VFDs can provide smooth ramp-up and ramp-down of motor speed, reducing mechanical stress and wear on the motor and connected equipment.

- Flexibility: They can easily be programmed to adjust to different operational requirements without the need for mechanical speed control devices like gears or pulleys.

- Improved Process Control: VFDs enable better process control by allowing for quick and accurate adjustments to motor speed. This is particularly beneficial in processes that require frequent changes in speed or torque.

- Reduced Mechanical Wear: vfd replace mechanical speed control mechanisms, VFDs reduce wear and tear on these components.