Level Switch – Types, Working Principle, Applications, and Uses

Published on July 25, 2024 | Category: introductionShare this Page:

Level switches, also known as level sensors, are essential devices used to detect the presence or absence of a fluid or solid material at a specific level within a container, tank, or silo. They come in a wide variety of designs—ranging from simple mechanical float switches to advanced electronic sensors—each tailored to different industrial requirements. Their primary purpose is to provide point-level detection (high or low alarms) or continuous monitoring of level conditions, ensuring safe, reliable, and automated process control.

In industrial environments, accurate level detection is critical. Whether it's a massive storage tank at a petrochemical plant, a mixing vessel in a food processing line, or a small container in a water treatment unit, maintaining the correct fluid or material level prevents overflow, dry running of pumps, contamination, or inefficient operation. For solid materials like grains, powders, or pellets stored in silos, level switches offer a similar function—providing timely alerts or data for inventory and safety management.

Depending on the application, different types of level switches are used—such as float switches for simple liquid detection, capacitive and ultrasonic sensors for non-contact measurement, vibrating fork switches for granular media, and optical or conductive types for specific chemical compatibility. Understanding their working principles, selection criteria, and practical use cases is vital for engineers, technicians, and automation professionals across industries.

What is a Level Switch?

A level switch is an industrial device used to detect when the level of a liquid, powder, or granular solid reaches a predetermined point inside a tank, vessel, or silo. It operates by opening or closing an electrical contact when the material level either rises to or falls below the set point. This switching action is used to trigger alarms, start or stop pumps, open or close valves, or initiate other control functions to maintain safe and efficient process conditions. Level switches can be designed for point-level detection (high-level or low-level) and are commonly found in applications requiring overflow protection, dry-run prevention, or batch level control. Depending on the sensing principle, they may work mechanically (e.g., float type), electronically (e.g., capacitive or ultrasonic), or vibrationally (e.g., tuning fork), each suited for specific media and operating environments.

Types of Level Switches

Level switches are classified based on their sensing technology, mechanical or electronic design, and the type of material they are intended to monitor. Below are the most widely used types of level switches in industrial applications:

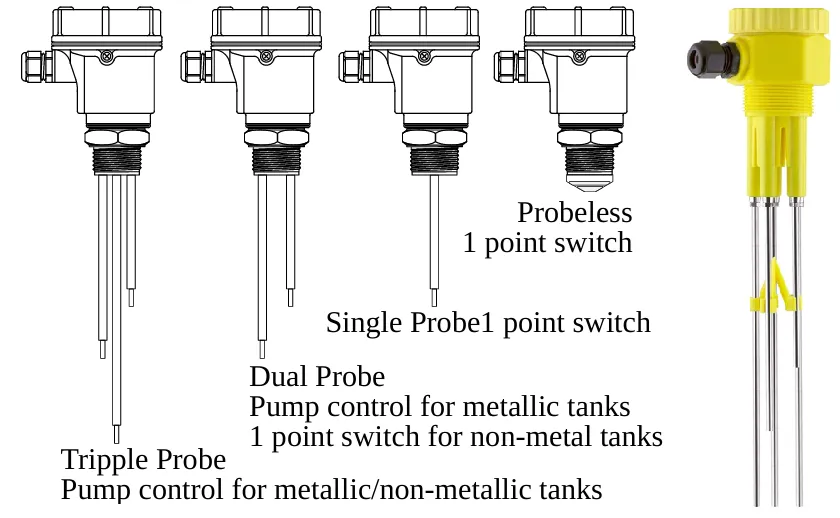

- Float Level Switch: Uses a buoyant float that rises/falls with liquid level to open or close a mechanical or reed switch.

- Conductivity Level Switch: Detects conductive liquids by completing an electrical circuit between probe electrodes.

- Capacitance Level Switch: Measures changes in capacitance when a solid or liquid material surrounds the probe.

- Vibrating (Tuning Fork) Level Switch: Uses a vibrating fork that stops resonating when covered by material, indicating level presence.

- Optical Level Switch: Uses infrared light refraction to detect the presence of clean, clear liquids at a fixed level.

- Ultrasonic Level Switch: Emits sound waves and detects level changes based on reflected signal disruption.

- Magnetic Level Switch: A magnet-equipped float moves with liquid and actuates a reed switch inside a sealed tube.

- Paddle (Rotary) Level Switch: A rotating paddle stalls when it contacts solid material, indicating the presence of bulk solids.

- Diaphragm Level Switch: Senses material pressure against a flexible diaphragm to trigger a mechanical switch.

Float Level Switch: Definition, Working Principle, Parts, and Applications

What is a Float Level Switch?

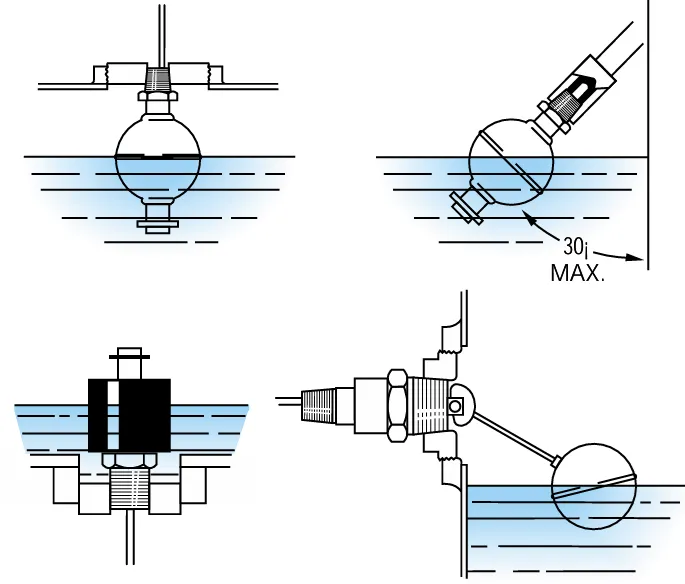

A float level switch is a mechanical device used to detect the level of liquid within a tank or vessel. It operates by utilizing a buoyant float that rises and falls with the liquid level. When the float reaches a certain high or low point, it activates a mechanical or magnetic switch that can trigger alarms, pumps, or other control devices. Float level switches are widely used for point-level detection in water, oil, and chemical tanks.

What is a Float Level Switch?

A float level switch is a simple and reliable device used to detect the level of liquid in a tank or vessel. It consists of a float that rises and falls with the liquid level, and a stem that contains a reed switch. When the float moves, it actuates the switch to control pumps, alarms, or valves.

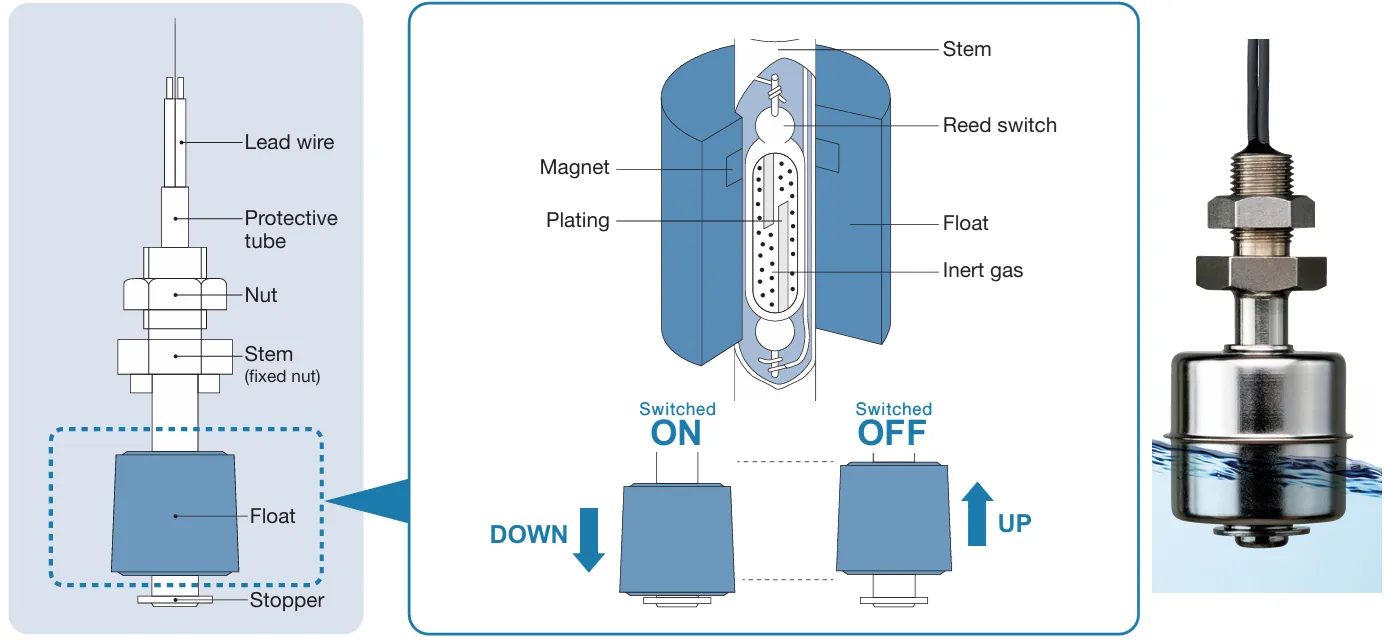

Float Level Switch Components

- Float: A buoyant body that moves with the liquid level.

- Stem: A vertical rod or tube that houses reed switches inside.

- Reed Switch: A magnetic contact switch triggered by the float's internal magnet.

- Magnet: Embedded inside the float to activate the reed switch when in proximity.

- Protective Tube: Encloses and protects the wiring and components.

- Lead Wire: Connects the switch to external control or monitoring circuits.

- Stopper & Nut: Provide mechanical support and position fixation for the float.

Working Principle of Float Level Switch

The float level switch operates based on the magnetic interaction between the float and the reed switch inside the stem. As the liquid level rises or falls, the float moves accordingly. The magnet inside the float causes the reed switch to change its state (NO to NC or vice versa) when it reaches a predefined point.

For example, when the liquid level goes up, the float rises and moves away from the switch, which may cause the switch to open (OFF). When the level drops, the float descends and closes the switch (ON). This contact change can then be used to trigger alarms, turn on/off pumps, or control valves.

These switches are ideal for single or multiple point level detection, and are suitable for both hazardous and non-hazardous environments. Some designs can include up to 5 reed switches for multipoint detection in a single probe.

Note: The default state is when the float is at the bottom. The reed switch state is maintained until the float position changes due to a change in liquid level.

Applications of Float Level Switch

- Water tanks for high/low level detection

- Oil and fuel level monitoring in storage tanks

- Boiler feed water tanks

- Wastewater treatment plants

- Cooling systems and HVAC equipment

- Industrial chemical storage tanks

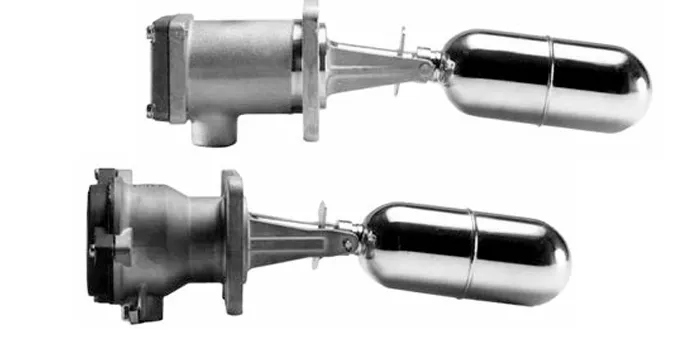

What is a Magnetic Level Switch?

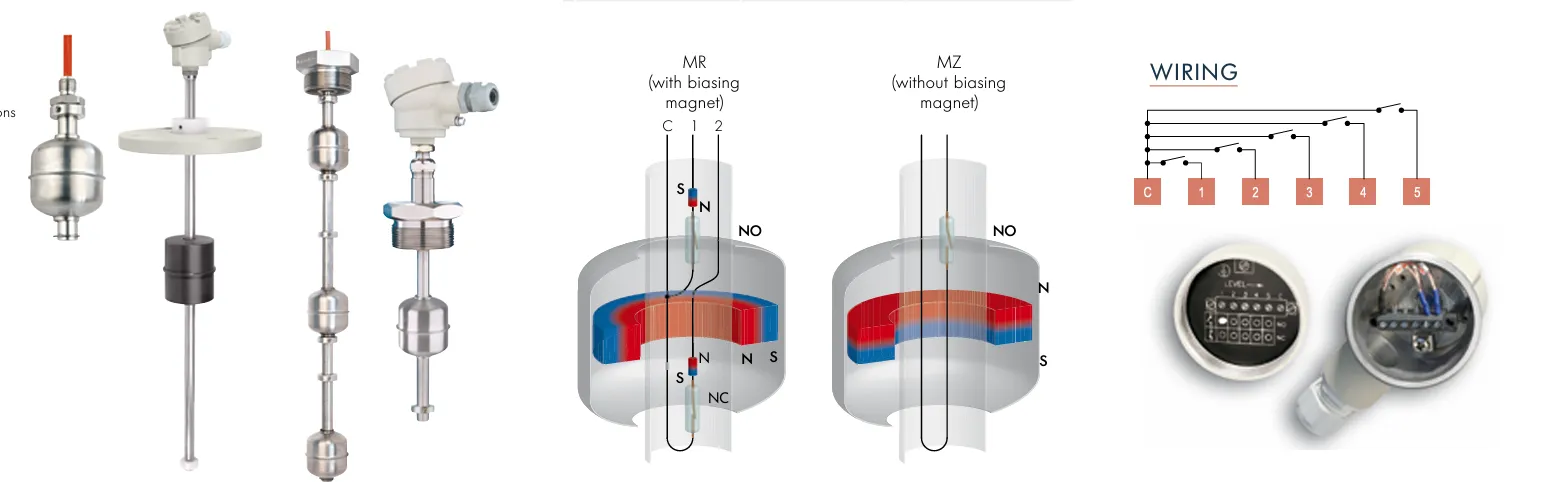

A magnetic level switch is a type of float-operated level sensor that uses a magnetic field to actuate a switch when a liquid level changes. It consists of a buoyant float containing a magnet, which moves along with the liquid level. As the float moves, its internal magnet activates a reed switch located in a sealed, non-magnetic stem. This non-contact switching action provides safe and reliable level detection, especially in closed or pressurized vessels.

Working Principle of Magnetic Level Switch

Magnetic level switches operate using the interaction between a magnet embedded in a float and one or more reed switches sealed inside a non-magnetic probe tube. As the liquid level rises or falls, the float moves vertically along the stem, following the level of the liquid. The magnet inside the float actuates the reed switches without any direct contact. When the float reaches the position of a reed switch, the magnetic field triggers the switch, changing its state from normally open (NO) to closed or from normally closed (NC) to open. This change remains latched (self-holding) until the liquid level drops again and the float moves away, returning the reed switch to its default state.

In multi-point level switches, several reed switches can be installed along the probe to detect multiple level points. These switches can independently control different output signals such as alarms, pump starters, or valve actuators. Miniature versions of magnetic float level switches may not include biasing magnets and are typically used for simpler, compact applications. The system typically includes a float, probe stem, and housing with terminal connections, and it is suitable for both safe and hazardous area installations.

Applications of Magnetic Level Switch

- Underground and overhead water tanks

- Fuel and diesel storage systems

- Pharmaceutical and chemical tanks

- Food and beverage processing vessels

- Boiler water level monitoring

- Sealed or pressurized containers

- Oil-water separator systems

Conductivity Level Switch

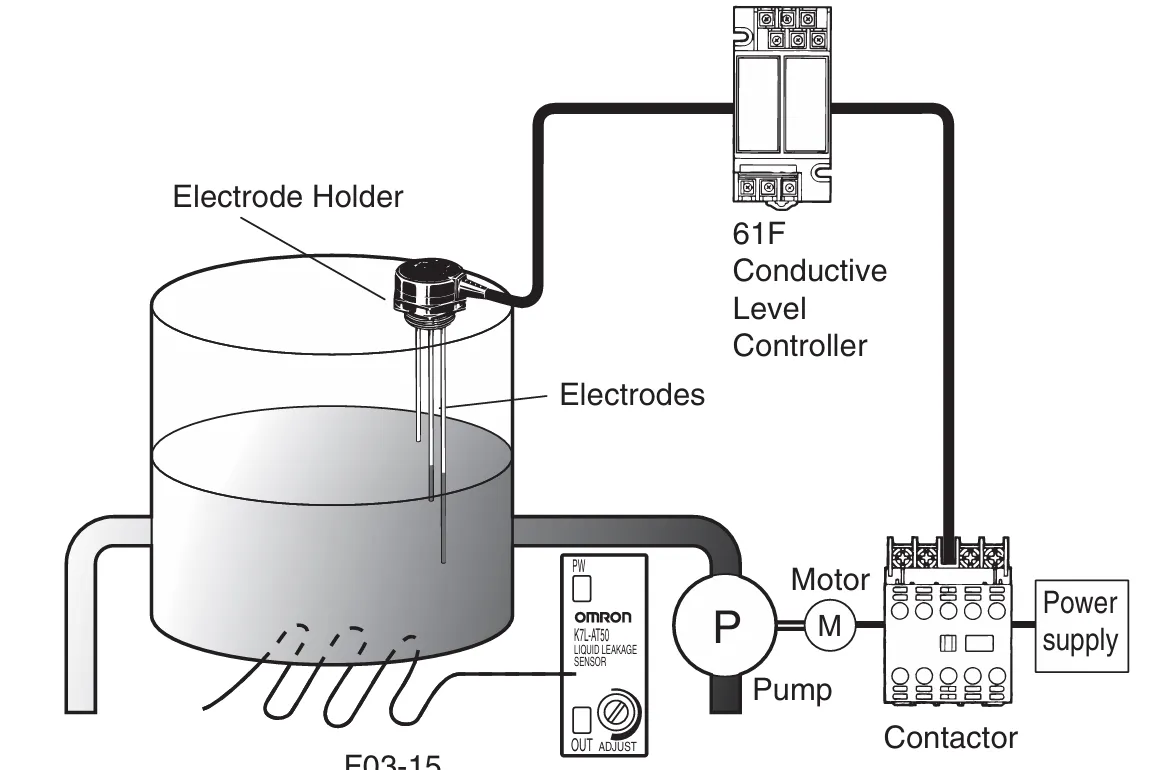

A conductivity level switch is an industrial device used to detect the presence or absence of conductive liquids at a specific level within a tank or vessel. These switches utilize the electrical conductivity of the liquid to complete or break a circuit between electrodes. They are ideal for high and low-level detection in applications involving water, acids, caustic solutions, and other conductive media.

Working Principle of Conductivity Level Switch

Conductivity level switches operate on the principle that conductive liquids can complete an electrical circuit. A low-voltage AC signal is sent between two or more electrodes immersed in the tank. When the liquid level rises and touches the probe, it forms a conductive path to complete the circuit. This signal is detected by the controller, which then activates a relay output.

As the level drops and the liquid no longer touches the probe, the circuit breaks, and the output switches off. The system uses AC voltage to avoid corrosion or electrolysis at the probe tips.

Components of Conductivity Level Switch

- Electrodes (Probes): Stainless steel rods or sensors that sense liquid contact.

- Electrode Holder: Provides insulation and spacing between the probes.

- Controller/Relay Module: Sends the signal and triggers output based on the circuit status.

- Mounting Arrangement: Threaded or flange-type fittings for installation in tanks.

Applications of Conductivity Level Switch

- Water tank high/low level detection

- Boiler drum level control

- Wastewater and effluent monitoring

- Chemical storage tank overflow protection

- Pump automation based on level detection

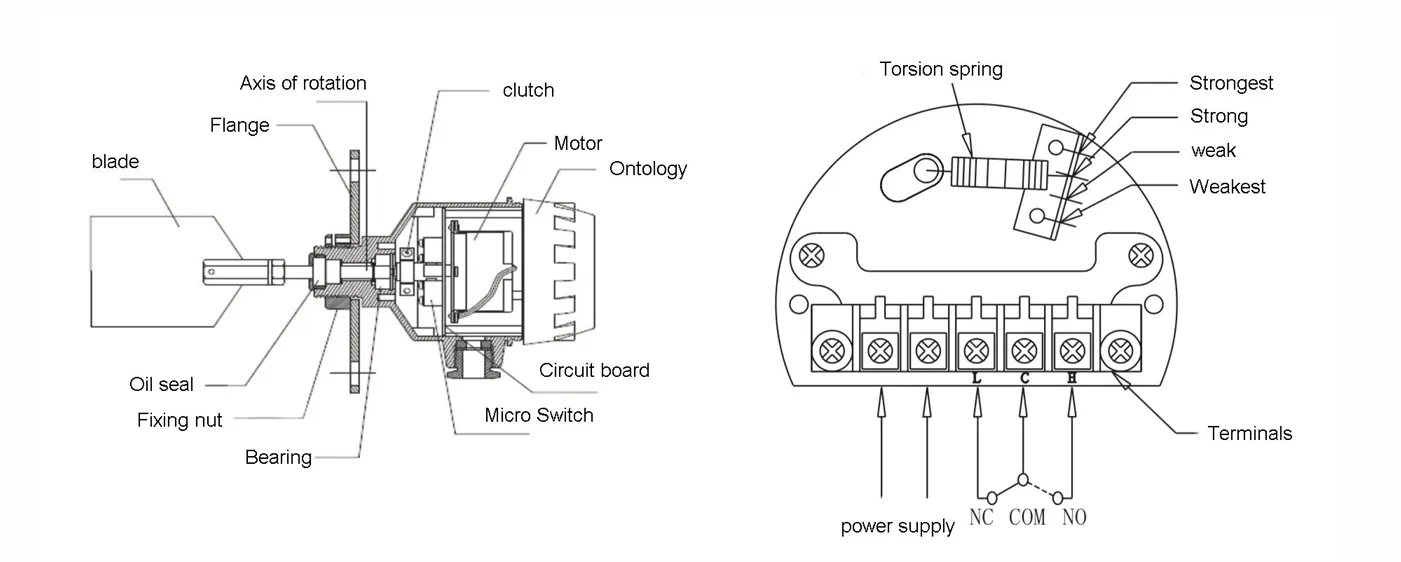

What is a Paddle (Rotary) Level Switch?

A paddle level switch, also known as a rotary level switch, is an industrial sensor used to detect the level of solid materials like powders, grains, or pellets in storage vessels. It operates using a rotating paddle mechanism that stops turning when it contacts material, indicating a full or intermediate level.

Types of Paddle Level Switches

- Standard Rotary Paddle Switch: General purpose, suitable for free-flowing solids.

- Extended Shaft Paddle Switch: Used in deep hoppers or tall silos with top mounting.

- Mini Paddle Switch: Compact design for small bins or restricted spaces.

- Explosion-Proof Paddle Switch: Designed for hazardous areas with flammable or dusty atmospheres.

Applications of Rotary Paddle Level Switch

- Level detection in cement silos, grain bins, and plastic hoppers.

- Overfill protection and low-level alarms in bulk material handling.

- Used in industries like food processing, fertilizers, cement plants, and chemicals.

Working Principle of Paddle Level Switch

The rotary paddle switch includes a motor, clutch, shaft, blade, and microswitch. The motor continuously rotates the paddle. When the paddle is not in contact with material, it rotates freely. As the material level rises and touches the paddle, the rotation is obstructed. This resistance triggers the clutch and activates a micro switch, sending a signal to the controller.

The internal spring tension (torsion spring) can be adjusted to match the material density using various settings such as Weakest, Weak, Strong, and Strongest.

Advantages of Rotary Paddle Level Switch

- Simple and reliable for point level detection in solids.

- Cost-effective for most bulk materials.

- Can be configured for top, side, or bottom mounting.

Limitations

- Not suitable for sticky, adhesive, or very light materials like foam.

- Requires proper torque adjustment for different material densities.

Vibrating (Tuning Fork) Level Switch

A vibrating (tuning fork) level switch is a point-level sensor used to detect the presence or absence of liquids or bulk solids at a specific level in a tank or hopper. It uses a vibrating fork (tines) that resonates at a natural frequency and changes its vibration pattern when covered by the process material. These switches are highly reliable and require minimal calibration, making them ideal for harsh or dusty environments.

Working Principle of Vibrating Level Switch

The tuning fork level switch operates based on changes in resonance. A piezoelectric crystal causes the fork to vibrate at its natural frequency in free air. When the fork is immersed in liquid or covered by solid material, the frequency and amplitude of vibration decrease due to damping. This change is detected by internal electronics, triggering a switch signal (ON/OFF). Once the material level drops and the fork is free again, it resumes vibrating and the switch resets.

Components of Vibrating Level Switch

- Tuning Fork: Vibrating metal prongs that detect material presence by damping effect.

- Piezoelectric Drive Unit: Generates and maintains vibration of the fork.

- Electronics Module: Detects frequency shift and provides relay or PNP/NPN output.

- Process Connection: Flanged or threaded fittings for easy tank installation.

- Enclosure: Sealed housing with IP rating for industrial conditions.

Applications of Vibrating Level Switch

- High and low-level alarms in storage tanks

- Powder and granular level detection in hoppers

- Viscous or foamy liquid detection in process vessels

- Dry run protection in pump tanks

- Dusty environments like cement or flour industries

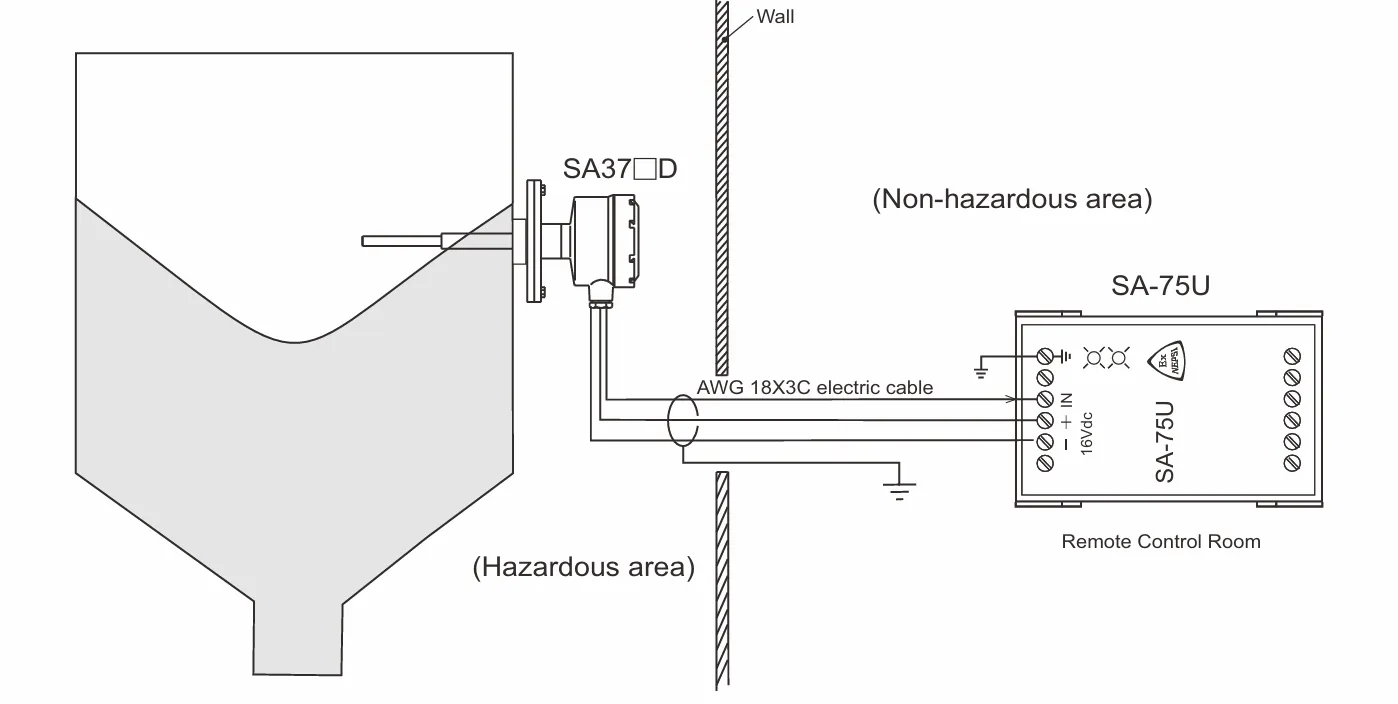

Capacitance Level Switch

A capacitance level switch is a contact-type point-level detection device used to detect the presence or absence of liquids or solids (like powders or granules) in a container or silo. It operates based on changes in capacitance caused by the presence of the process material between a sensing probe and the container wall. These switches are widely used in industries for level measurement of non-conductive or dielectric materials such as oils, grains, chemicals, and plastic pellets.

Working Principle of Capacitance Level Switch

The capacitance level switch works on the principle that any change in the dielectric constant between the sensing probe and the tank wall causes a measurable change in capacitance. When the material level rises and surrounds the probe, the dielectric constant of the medium increases, altering the capacitance. The electronics inside the switch detect this change and trigger a switching output (NO/NC), indicating level presence or absence. When the level falls, the capacitance decreases and the switch resets.

Components of Capacitance Level Switch

- Sensing Probe: Rod or cable-type electrode inserted into the tank to detect capacitance change.

- Housing/Enclosure: Contains the electronics and switching circuit, usually IP-rated for protection.

- Signal Processing Unit: Converts capacitance variation into ON/OFF switching signal.

- Mounting Connection: Threaded or flanged fitting to install on tanks or silos.

Applications of Capacitance Level Switch

- Oil and fuel tank level detection

- Plastic pellets or powder silo monitoring

- Food and beverage industry for grains and sugar

- Chemical and pharmaceutical tank level detection

- High and low-level alarms in non-conductive liquids

What is an Ultrasonic Level Switch?

An ultrasonic level switch is a non-contact type level sensing device that uses high-frequency ultrasonic sound waves to detect the presence or absence of liquids or solids at a specific point in a tank or vessel. It is widely used in industrial applications for level detection, overflow alarms, and pump control where direct contact with the medium is undesirable.

Working Principle of Ultrasonic Level Switch

The ultrasonic level switch works by emitting a short burst of high-frequency sound waves from a piezoelectric transducer. These waves travel through air and reflect back when they hit the surface of a liquid or solid. The device measures the time taken for the echo to return and calculates the level. If the measured level crosses the predefined switching point, it changes the state of an output signal (NO or NC), thereby triggering control actions like alarms or pump start/stop.

Key Components

- Ultrasonic Transducer: Generates and receives ultrasonic pulses.

- Control Unit: Processes the echo signals and compares them with setpoints.

- Power Supply and Relay Output: Provides control signals based on level detection.

Applications of Ultrasonic Level Switch

- Tank level detection in water treatment plants.

- Overflow and dry run protection for storage vessels.

- Non-contact level measurement in hazardous, corrosive, or high-temperature liquids.

- Widely used in chemical, pharmaceutical, and food processing industries.

Advantages

- Non-contact operation eliminates wear and contamination.

- High reliability and accuracy for both solids and liquids.

- Maintenance-free operation with no moving parts.

Limitations

- Performance affected by heavy dust, foam, or vapors.

- Requires clear path between sensor and target surface.

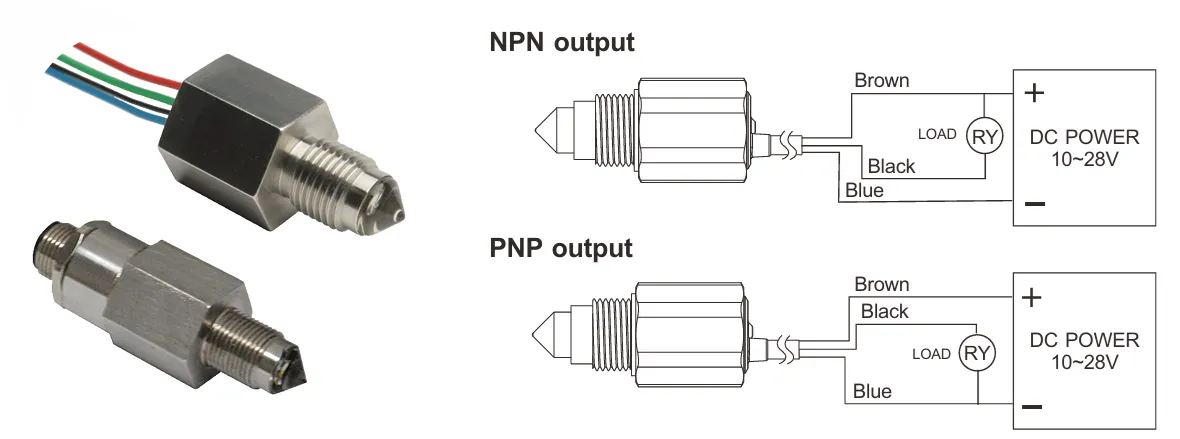

Optical Level Switch

An optical level switch is a compact, non-mechanical device used for point-level detection of liquids. It works by using infrared light to detect the presence or absence of a liquid at a fixed point. These switches are ideal for applications requiring high reliability, no moving parts, and fast response time — commonly used in clean liquids or harsh chemical environments.

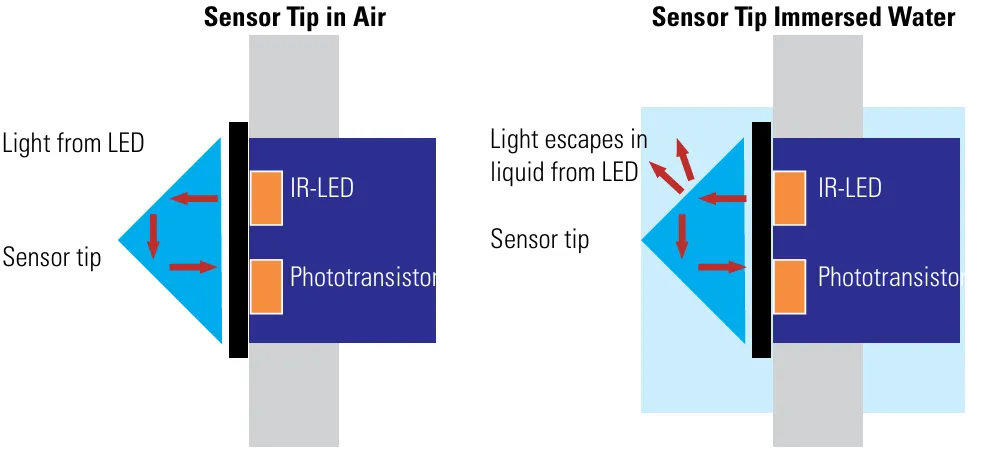

Working Principle of Optical Level Switch

The optical level switch operates based on the refraction of infrared light. A light-emitting diode (LED) sends an infrared beam through a prism-shaped sensor tip. In air, the light beam reflects internally and returns to the detector. When the liquid covers the tip, the refractive index changes, causing the light to scatter or refract away from the detector. This shift in light intensity is used to trigger a switching output. The result is a precise ON/OFF signal without contact with moving components.

Components of Optical Level Switch

- Infrared LED: Emits a focused light beam into the prism sensor tip.

- Phototransistor (Detector): Detects reflected or refracted light based on the medium.

- Sensing Prism Tip: Optical glass or plastic tip that interacts with the medium.

- Electronics Circuit: Interprets signal change and generates output (relay or transistor).

- Housing: Chemically resistant body for tank or pipe mounting (often plastic or stainless steel).

Applications of Optical Level Switch

- Leak detection in pipelines or containers

- Level monitoring in chemical dosing tanks

- Compact tanks in medical and food industries

- Low-level alarm in hydraulic and lubrication systems

- Battery electrolyte monitoring