What is a Level Transmitter? Types, Working, and Applications in Industrial Instrumentation

Published on July 4, 2024 | Category: introductionShare this Page:

Explore the fundamentals of level transmitters, including their types such as ultrasonic, radar, and differential pressure transmitters. Understand how level measurement is used in industrial processes to monitor liquids, solids, and slurries in tanks, silos, and pipelines. This information is ideal for instrumentation professionals and engineers.

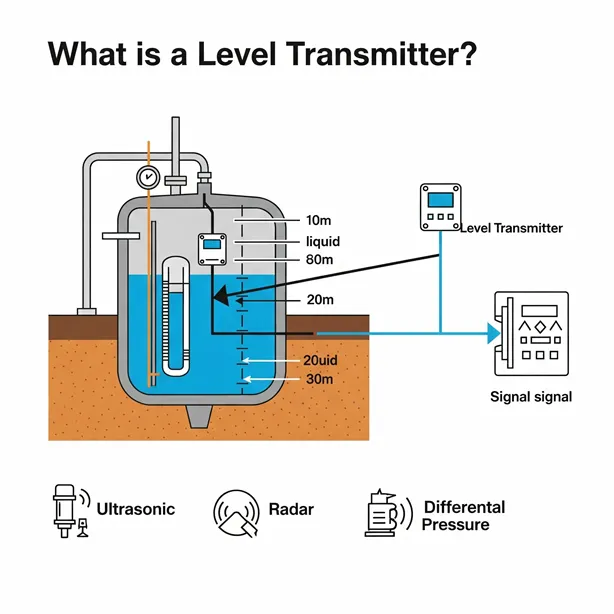

Level transmitters are essential components in industrial instrumentation, used for accurately measuring the level of liquids, solids, or slurry in tanks, vessels, and pipelines. These devices provide continuous or point level measurement and are critical for process control, safety, and inventory management in industries such as water treatment, food and beverage, oil and gas, and chemical manufacturing.

A level transmitter is an instrument that provides continuous level measurement. Level transmitters are used to determine the level of a specific bulk solid or liquid at any given time. They differ from level switches, which only trigger an alarm when the material reaches a predefined level.

There are several types of level transmitters, including ultrasonic, radar, capacitive, magnetostrictive, and differential pressure transmitters. Each type is suited for specific applications based on factors such as material type, tank size, pressure, and temperature. Understanding how level transmitters work and where they are used ensures accurate monitoring and efficient operation of industrial systems.

This guide explains the working principles, classifications, selection criteria, and real-world applications of level transmitters. It is designed to help engineers and instrumentation professionals make informed decisions when designing or maintaining level measurement systems.

What is a Level Transmitter?

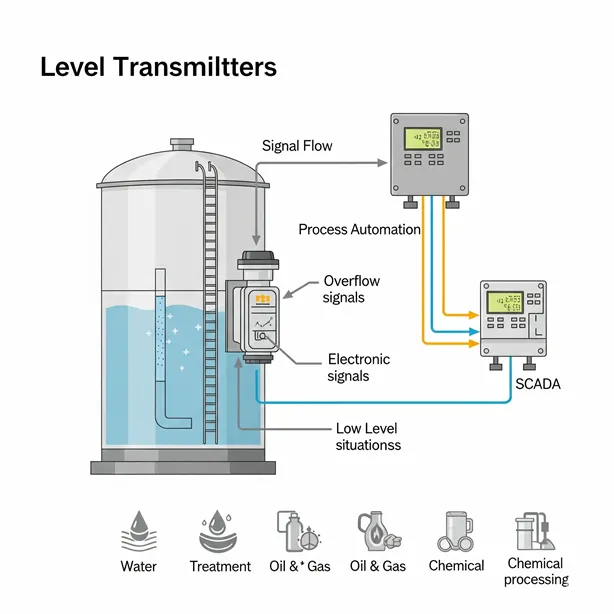

A level transmitter is an industrial device used to measure and monitor the level of materials—such as liquids, powders, or granular substances—within a container, tank, silo, or pipeline. Unlike level switches that only detect specific level points (e.g., high or low level alarms), level transmitters provide continuous level measurement, delivering real-time analog or digital output signals that represent the current level within a vessel.

What is a Level Transmitter in Instrumentation?

In instrumentation, a level transmitter is an essential sensor used for process automation and control. It continuously monitors material levels and converts this data into electrical signals that are sent to controllers, PLCs, or SCADA systems. These signals help maintain optimal operating conditions by automating tasks such as tank filling, emptying, or alarming in case of overflow or low levels. Level transmitters play a vital role in industries such as chemical processing, water treatment, oil and gas, and food manufacturing.

Level Measurement in Industrial Instrumentation

Level measurement is a crucial aspect of industrial instrumentation. It ensures safe, efficient, and consistent monitoring of material quantities within process systems. Accurate level measurement prevents overflows, underfills, and equipment damage, and helps manage inventory levels. Level measurement can be categorized into two types: point level detection (detects high/low levels only) and continuous level measurement (monitors the entire level range). Level transmitters support continuous monitoring and are chosen based on material type, vessel geometry, environmental conditions, and process pressure/temperature.

Role of Level Transmitters in Industrial Processes

Level transmitters play a key role in various industrial processes by:

- Providing real-time feedback for liquid, solid, or slurry levels.

- Improving process control by maintaining stable levels in tanks and silos.

- Enhancing safety by avoiding overflow or dry run conditions.

- Enabling inventory management by tracking material availability.

- Ensuring regulatory compliance by monitoring hazardous or pressurized substances.

Basic Working Principle of Level Transmitters

Level transmitters operate on various physical principles depending on the type. The general working principle involves detecting the position or height of the material surface and converting it into an electrical signal. For example:

- Ultrasonic and Radar: Emit waves that reflect off the material surface. The time taken for the echo to return is used to calculate the level.

- Differential Pressure: Measures the pressure difference between the bottom and top of the tank to determine the material height.

- Capacitive: Measures changes in capacitance caused by material presence between two conductive plates.

- Magnetostrictive: Detects the position of a float with a magnetic field along a wire using torsional waves.

Types of Level Transmitters (List Only)

- Ultrasonic Level Transmitter

- Radar (Microwave) Level Transmitter

- Guided Wave Radar Level Transmitter

- Capacitance Level Transmitter

- Magnetostrictive Level Transmitter

- Differential Pressure (DP) Level Transmitter

- Hydrostatic Level Transmitter

- Laser Level Transmitter

- Optical Level Transmitter

- Float-Based Level Transmitter

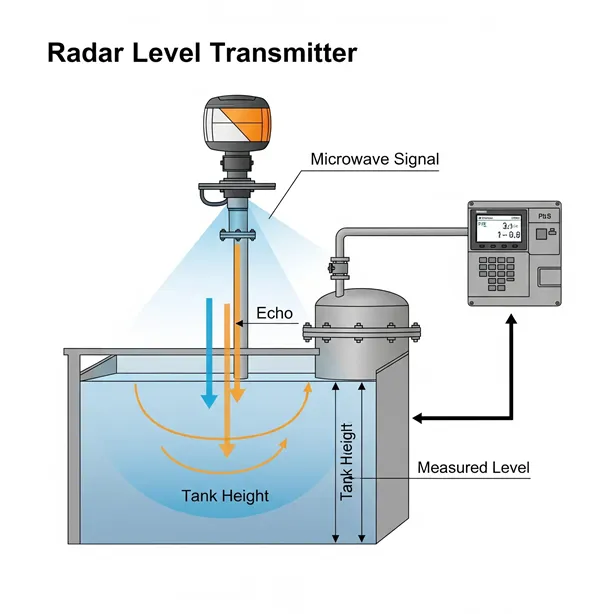

What is a Radar Type Level Transmitter?

A radar type level transmitter is a non-contact level measurement device that uses high-frequency microwave radar pulses to measure the level of liquids, slurries, or solids in industrial tanks and silos. It operates effectively even under challenging conditions like high temperature, pressure, dust, or vapor. Radar transmitters are known for their precision and reliability, especially in corrosive or hygienic environments.

Radar Type Level Transmitter – Working Principle and Uses

Radar level transmitters work based on the principle of **time-of-flight measurement**. The transmitter emits electromagnetic microwave signals (typically in the GHz range) toward the surface of the material. These waves reflect back from the surface, and the time it takes for the echo to return is measured. The distance is calculated using the formula:

Distance = (Speed of Light × Time Delay) / 2

Since the distance from the transmitter to the surface is known, and the total height of the tank is known, the level is calculated by subtraction. These transmitters are often used where contact-based sensors may degrade due to temperature, pressure, chemical interaction, or buildup.

Applications of Radar Level Transmitter

Radar level transmitters are widely used in industries where accurate and hygienic or harsh-environment measurement is critical. Common applications include:

- Monitoring chemical storage tanks

- Measuring levels in oil refineries and fuel depots

- Food and beverage processing (hygienic designs)

- Slurry tanks in mining operations

- Water and wastewater treatment plants

- Powdered or granular solid level monitoring in silos

Their ability to function without physical contact makes them ideal for use with corrosive, pressurized, or hot materials.

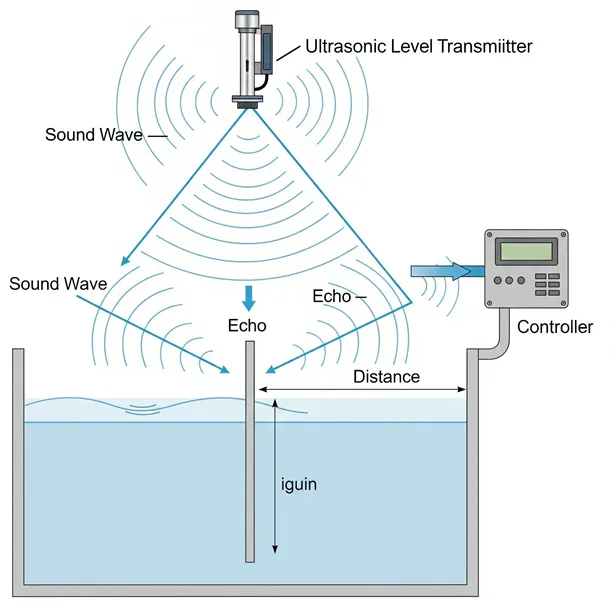

What is an Ultrasonic Level Transmitter?

An ultrasonic level transmitter measures level by emitting sound waves and detecting the echo reflected from the surface of the material. It is also a non-contact type and is cost-effective for simple applications.

Ultrasonic Level Transmitter – Working Principle and Uses

It operates by sending high-frequency sound pulses downward. When these pulses hit the material surface, they bounce back. The time taken for the echo to return is measured, and the distance (and hence level) is calculated.

Applications of Ultrasonic Level Transmitter

- Open channel water flow measurement

- Storage tanks for non-volatile liquids

- Wastewater treatment plants

- Sewage and sludge tanks

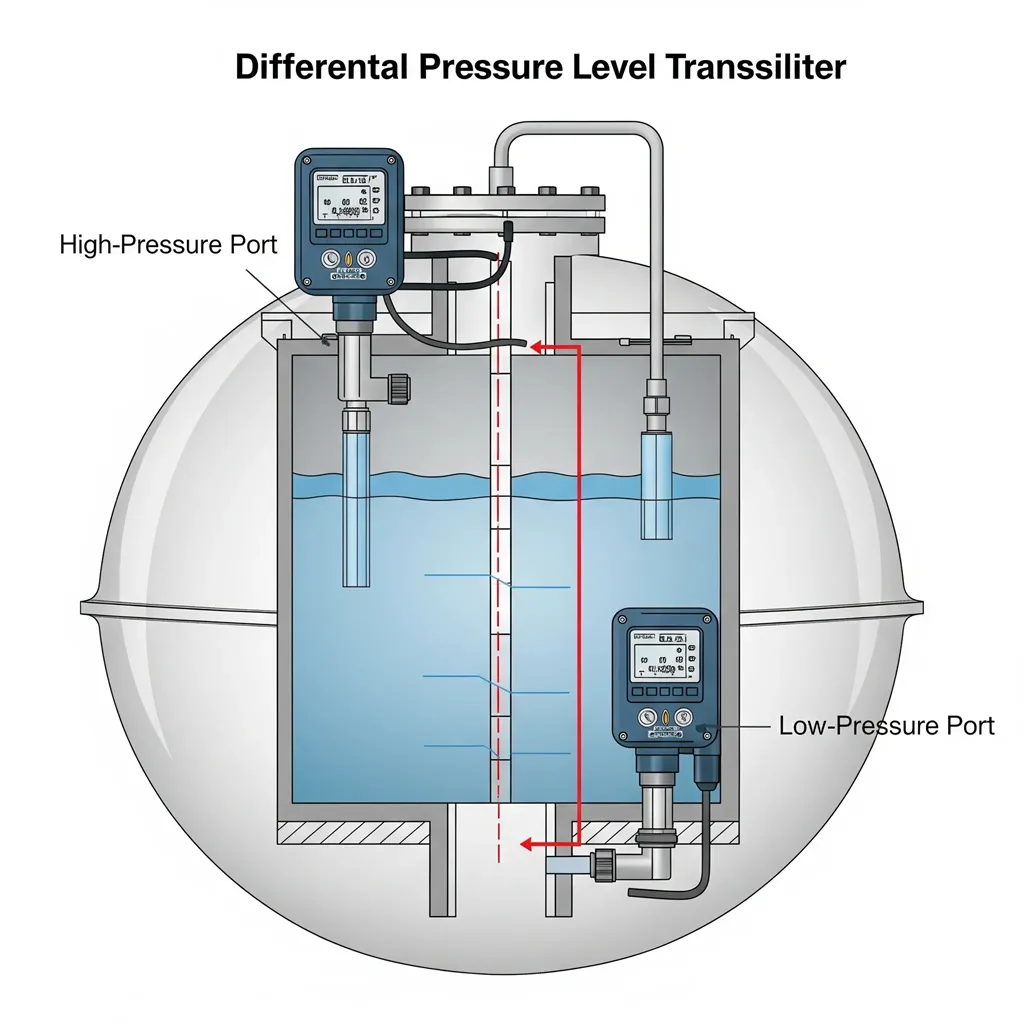

What is a Differential Pressure Level Transmitter?

A DP level transmitter measures the pressure difference between two points in a tank to calculate the level of the material. It is a contact-type method.

Differential Pressure Level Transmitter – Working Principle and Uses

The transmitter senses the pressure at the bottom of the tank and compares it to a reference pressure (usually the top or atmospheric). The pressure difference corresponds to the height of the liquid column.

Applications of DP Level Transmitter

- Pressurized liquid tanks

- Boiler drum level measurement

- Chemical reactor vessels

- Crude oil storage with vapor pressure

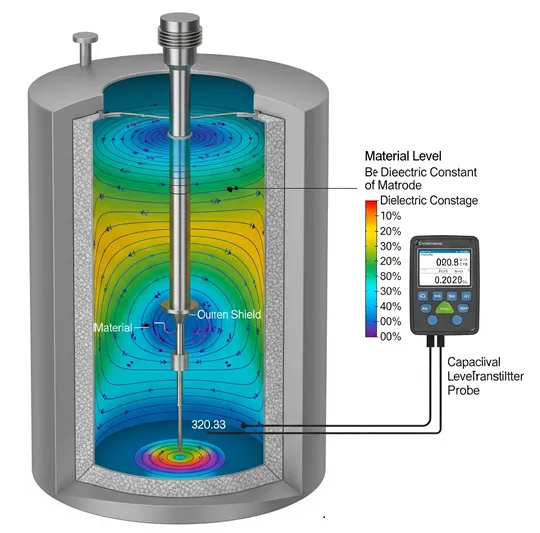

What is a Capacitance Level Transmitter?

A capacitance level transmitter measures changes in electrical capacitance between the probe and tank wall due to material level variation.

Capacitance Level Transmitter – Working Principle and Uses

As the level changes, the dielectric constant of the material between the probe and tank wall changes, altering the capacitance. This change is processed to determine the level. It can be used for both liquids and solids.

Applications of Capacitance Level Transmitter

- Viscous liquid tanks (e.g., syrups, oil)

- Powder level detection in silos

- Low dielectric material measurement

- Food-grade processes with sanitary fittings

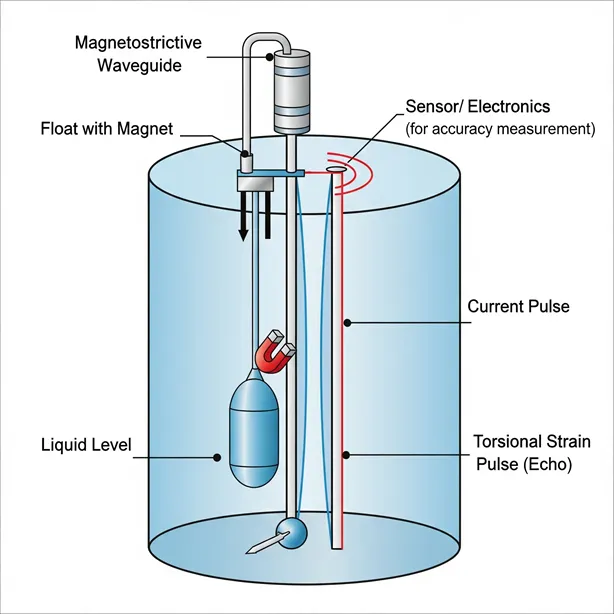

What is a Magnetostrictive Level Transmitter?

This transmitter uses a float containing a magnet that moves with the material level along a waveguide. It is known for high precision and is widely used in fuel and oil tanks.

Magnetostrictive Level Transmitter – Working Principle and Uses

A pulse is sent down the waveguide, which interacts with the magnetic float, creating a torsional strain wave. The time taken for this wave to return is used to calculate the float's position, and thus, the material level.

Applications of Magnetostrictive Level Transmitter

- Underground fuel tanks

- Liquid propane and butane level measurement

- Food and beverage process tanks

- Pharmaceutical industry

What is a Magnetostrictive Level Transmitter?

This transmitter uses a float containing a magnet that moves with the material level along a waveguide. It is known for high precision and is widely used in fuel and oil tanks.

Magnetostrictive Level Transmitter – Working Principle and Uses

A pulse is sent down the waveguide, which interacts with the magnetic float, creating a torsional strain wave. The time taken for this wave to return is used to calculate the float's position, and thus, the material level.

Applications of Magnetostrictive Level Transmitter

- Underground fuel tanks

- Liquid propane and butane level measurement

- Food and beverage process tanks

- Pharmaceutical industry

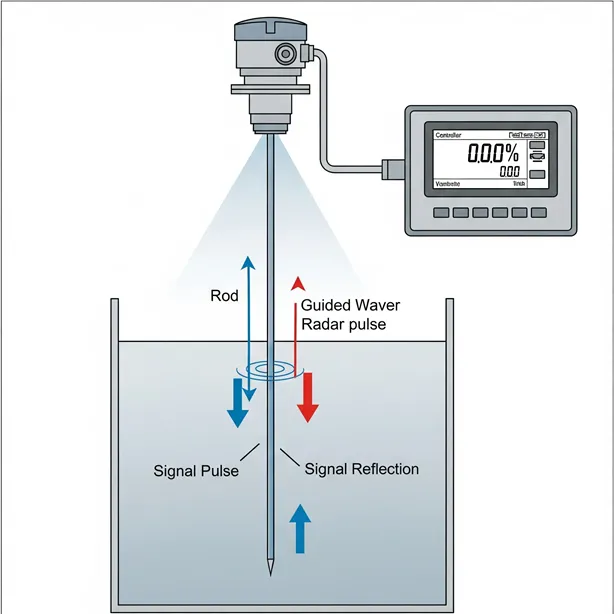

What is a Guided Wave Radar Level Transmitter?

A guided wave radar (GWR) level transmitter is a contact-based radar device that sends microwave pulses down a probe (rod or cable) to detect the level of liquids, slurries, or solids.

Guided Wave Radar Level Transmitter – Working Principle and Uses

GWR transmitters operate by sending electromagnetic pulses down a probe that extends into the process material. When the pulse hits the material surface, part of the energy reflects back. The time delay of the reflected signal is used to calculate the level. It provides high accuracy even with vapors, foam, or agitation.

Applications of Guided Wave Radar Level Transmitter

- Viscous or sticky liquids in narrow tanks

- Heavy foam or vapor conditions

- Storage tanks with small nozzles

- Interface level (oil-water separation)

What is a Float Type Level Transmitter?

A float type level transmitter uses a float that rises and falls with the liquid level. Its movement is converted into an electrical signal to measure level continuously.

Float Type Level Transmitter – Working Principle and Uses

The float contains a magnet or is mechanically linked to a transmitter. As the liquid level changes, the float moves vertically. This movement is detected using magnetic coupling, resistance change, or mechanical linkage to provide level indication.

Applications of Float Type Level Transmitter

- Underground diesel or fuel tanks

- Lubricant storage and level control

- Water level in pump stations

- Simple and economical level monitoring

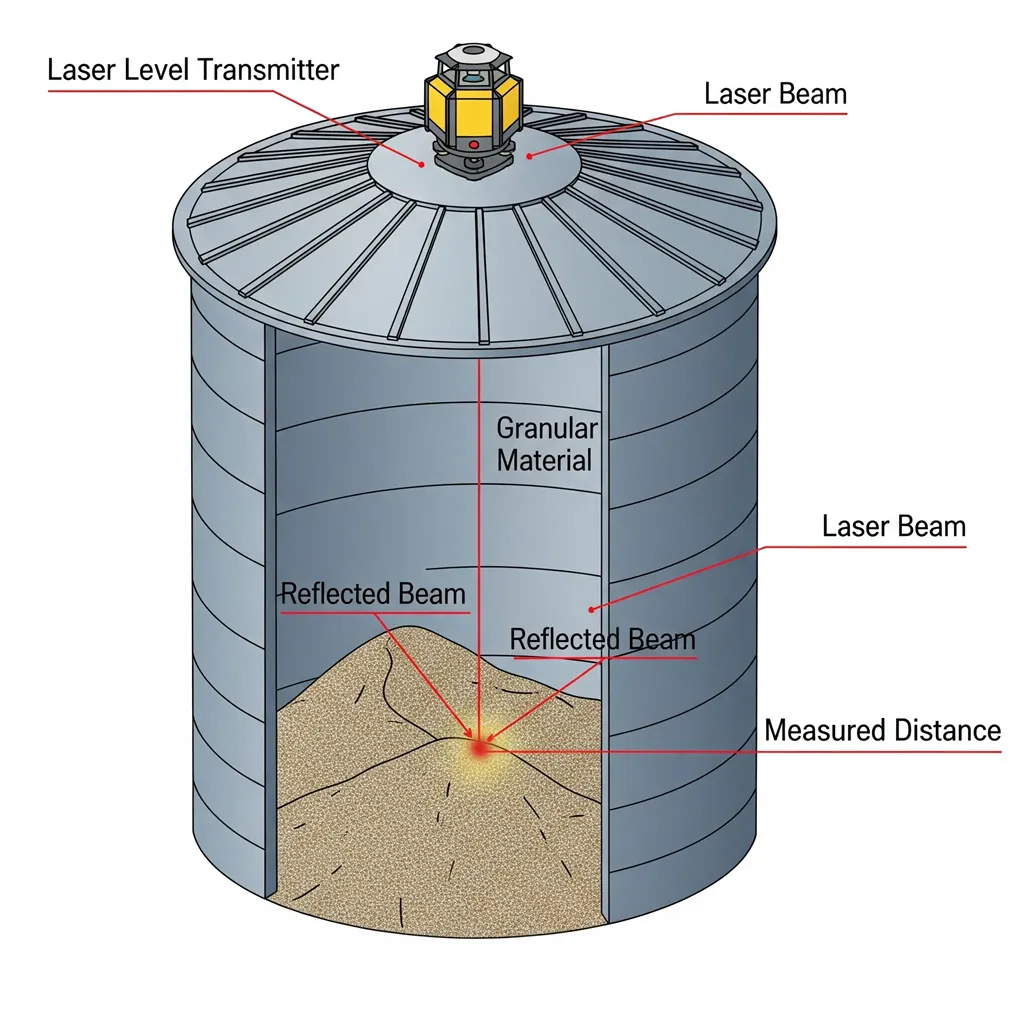

What is a Laser Level Transmitter?

A laser level transmitter uses a narrow beam of laser light to measure the distance to the material surface, offering extremely precise non-contact level measurement.

Laser Level Transmitter – Working Principle and Uses

The transmitter emits a focused laser beam toward the surface. The reflected signal's time delay is analyzed to calculate distance. It's especially effective for long-range measurements and applications where high resolution is required.

Applications of Laser Level Transmitter

- Long-distance silo level monitoring

- Mining and bulk solids (gravel, coal)

- Precise non-contact measurement for powders

- High-precision inventory systems

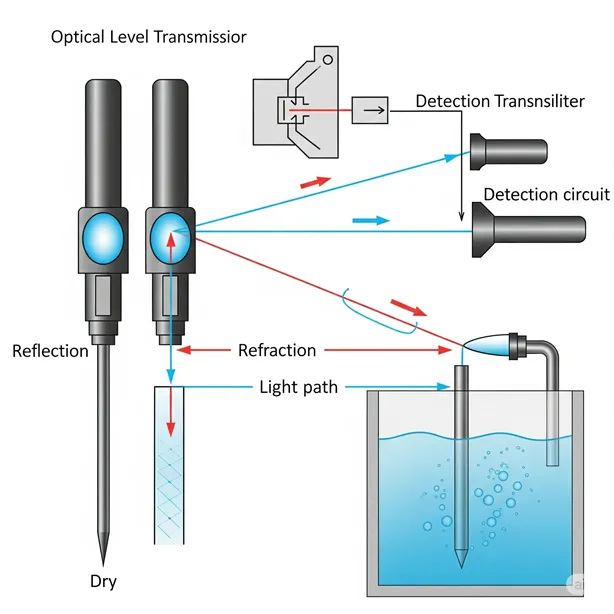

What is an Optical Level Transmitter?

An optical level transmitter uses infrared light to detect the presence or absence of a liquid at a specific level point. It is a point-level sensor, not continuous.

Optical Level Transmitter – Working Principle and Uses

A light source and receiver are embedded in a probe. When the probe is dry, the light reflects internally and returns to the receiver. When immersed in liquid, the light is refracted into the liquid, causing a signal change. This change is used to detect whether the liquid level has reached the sensor tip.

Applications of Optical Level Transmitter

- Leak detection in pipelines

- Tank overfill protection

- Compact point-level detection in small vessels

- Medical and laboratory applications