Learn what PNP and NPN proximity sensor switches are, how they work, their differences, and common applications in industrial automation and PLC control systems.

Published on July 2, 2024 | Category: ProximityShare this Page:

Proximity sensors or switches detect objects without any direct physical contact. These sensors are widely used in industrial environments to detect objects such as metals, plastic components, or machine parts. In industrial automation, proximity switches are commonly available in 2-wire and 3-wire configurations, with 3-wire PNP or NPN types being the most popular, offering various power supply options and sensing ranges.

A PNP-type proximity switch is also known as a 'sourcing' sensor, while an NPN-type is known as a 'sinking' sensor. The selection between PNP and NPN proximity switches depends on several factors:

- The type of electrical control system

- The input type accepted by the PLC or controller

- The sensing range and operating frequency

- Power supply voltage and target material

PNP sensors are more commonly used in European systems, while NPN sensors are widely preferred in Asian and American automation setups.

Both NPN and PNP proximity sensors are available in either Normally Open (NO) or Normally Closed (NC) configurations. This determines whether the output signal is active when an object is detected or not. It's important to note that the NO/NC configuration is separate from the PNP/NPN type and should not be confused. Understanding this distinction is essential when designing or troubleshooting automation systems.

In traditional control circuits using relays or contactors, either PNP or NPN proximity switches can be used depending on the control wiring scheme. Each sensor type uses a different internal transistor arrangement, which affects how current flows through the output during detection. Choosing the correct sensor type ensures compatibility with control hardware and minimizes wiring errors.

This page serves as a complete guide for both beginners and experienced professionals. It covers the working principles, sensor types, internal circuitry, and practical wiring examples of PNP and NPN proximity sensors with PLCs. Whether you're installing sensors in machines, diagnosing faults in field wiring, or planning a control panel layout — understanding the difference between PNP and NPN sensors is essential for reliable automation system design.

What is a PNP Proximity Sensor?

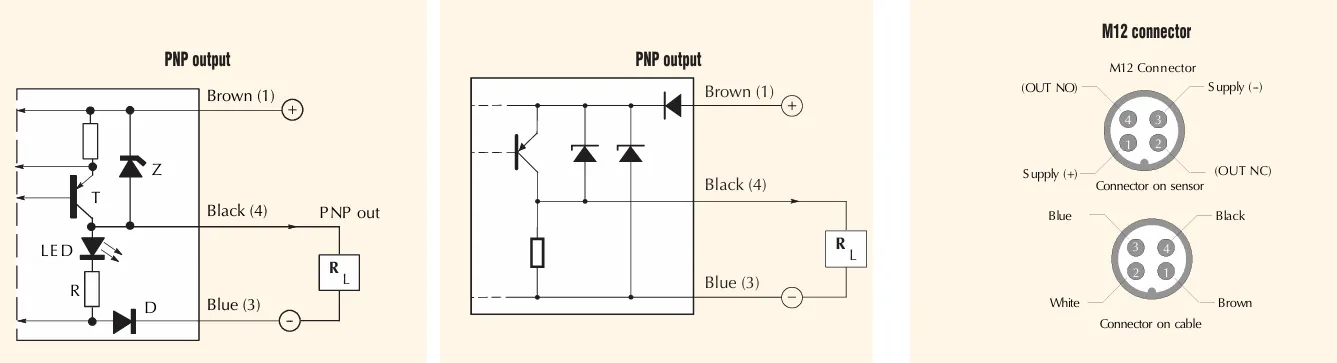

A PNP proximity sensor is a type of electronic sensor that detects the presence of an object (usually metal) without making physical contact. In a PNP sensor, when the sensor detects an object, it connects the load to the positive supply voltage, allowing current to flow from the sensor to the input device (such as a PLC). This is why PNP is also referred to as a "sourcing" sensor.

Working Principle of PNP Proximity Sensor

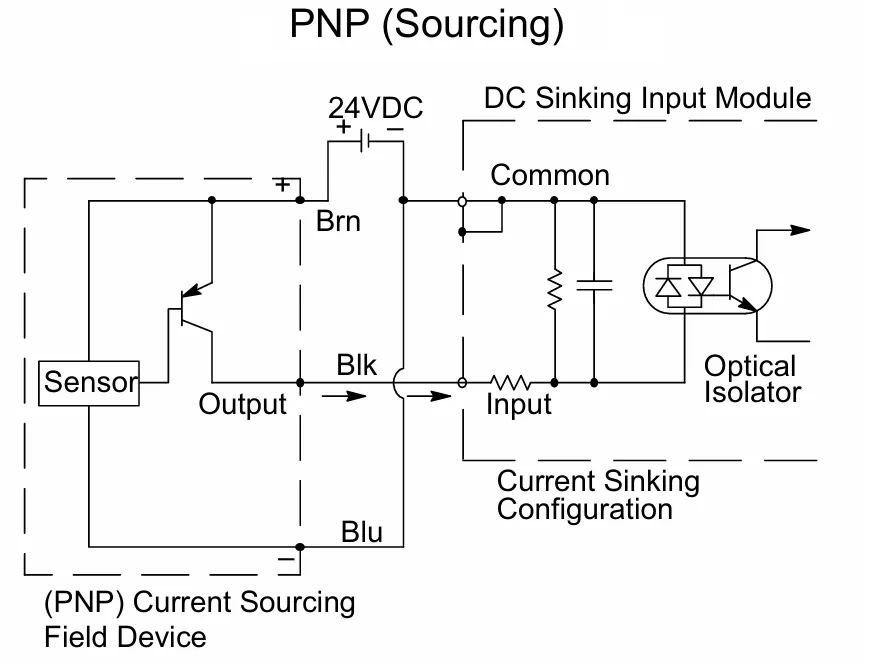

A PNP proximity sensor, also called a sourcing sensor, provides positive voltage to the output when an object is detected. It is widely used in industrial automation and is compatible with DC sinking input modules in PLCs.

The PNP sensor has three wires:

- Brown (Brn): +24V DC (Power supply)

- Blue (Blu): 0V DC (Ground)

- Black (Blk): Output signal to load or PLC input

When a metallic or target object is detected near the sensing face, the internal transistor switches ON and connects the output (black wire) to the +24V line. This allows current to flow out of the sensor, through the connected load (e.g., PLC input or LED), and then to ground.

How Current Flows:

- The output becomes HIGH (24V) when the object is detected.

- Current flows: Sensor → Load → Ground.

- This energizes the input device, activating the corresponding logic in the controller.

When no object is detected, the sensor's output remains disconnected (OFF), and no current flows through the load. The input module sees this as an inactive state.

Key Points:

- PNP = Sourcing output (positive voltage on detection)

- Connects to DC sinking input (current flows into ground)

- Output is HIGH (24V) when active

PNP sensors work by generating an electromagnetic field at the sensing face. When a target object enters this field, the sensor detects a change and activates the internal transistor circuit. The output terminal switches to a high voltage level (+V), allowing current to flow into the load (such as a PLC input). The sensor typically has three wires: one for power supply (+V), one for ground (0V), and one for the output signal.

Applications of PNP Proximity Sensors

PNP sensors are widely used in:

- Industrial automation and machine control

- Position and object detection in assembly lines

- Conveyor systems and packaging machines

- Metal detection in robotic arms and CNC machines

- Automated inspection systems

Properties of PNP Proximity Sensors

Common properties and specifications of PNP sensors include:

- Sensing Distance: 2 mm to 20 mm (depends on sensor size and type)

- Operating Voltage: 10V to 30V DC

- Output Type: PNP (sourcing) – Normally Open (NO) or Normally Closed (NC)

- Frequency Response: Up to 2 kHz (depending on model)

- Target Material: Usually ferrous metals (iron, steel); non-ferrous may require special models

- Protection: Short-circuit and reverse polarity protection

What is a 2-Wire PNP Sensor?

A 2-wire PNP proximity sensor uses only two wires to provide both power and output signal. It is typically connected in series with the load. These are less common and generally used where wiring space is limited. The sensor must be carefully matched with the input device to ensure reliable switching.

What is a 3-Wire PNP Sensor?

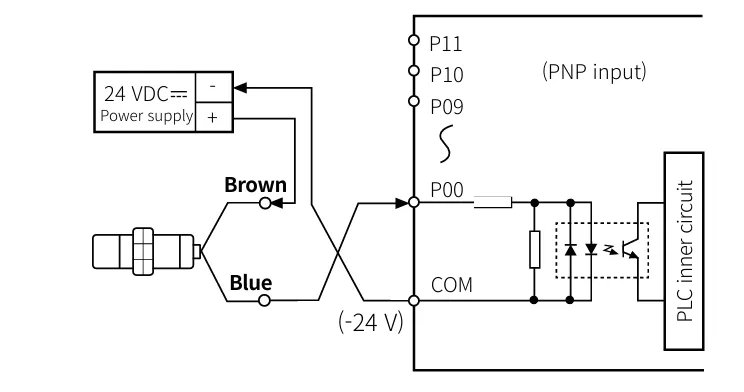

A 3-wire PNP proximity sensor is the most commonly used configuration. It has three wires:

- Brown: +V supply (typically 24V DC)

- Blue: 0V (Ground)

- Black: Output signal

What is an NPN Proximity Sensor?

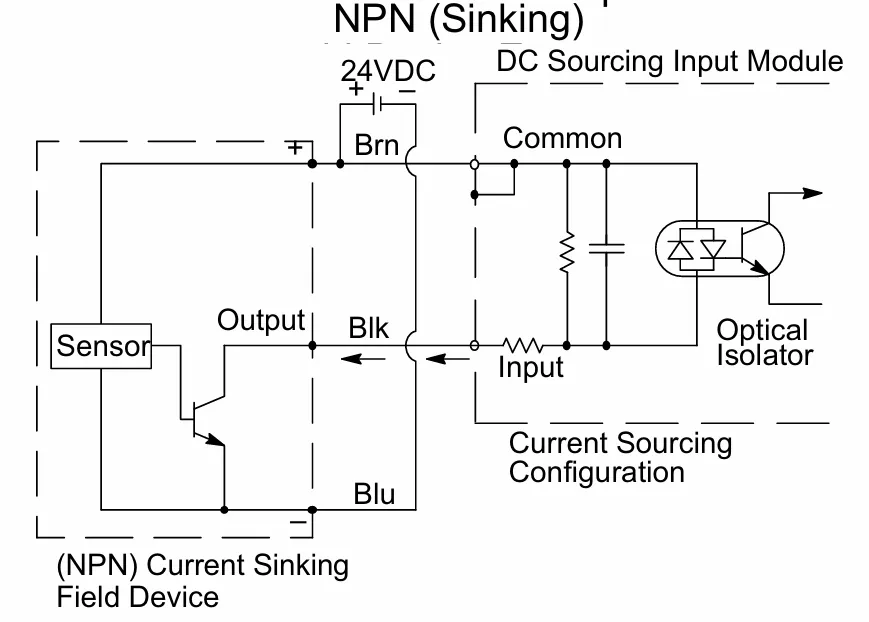

An NPN proximity sensor is a type of non-contact electronic switch used to detect the presence of nearby objects, typically metal. In an NPN sensor, when the sensor is activated, the output switches to ground (0V), and current flows from the input device (like a PLC) into the sensor. This is why NPN sensors are referred to as "sinking" sensors.

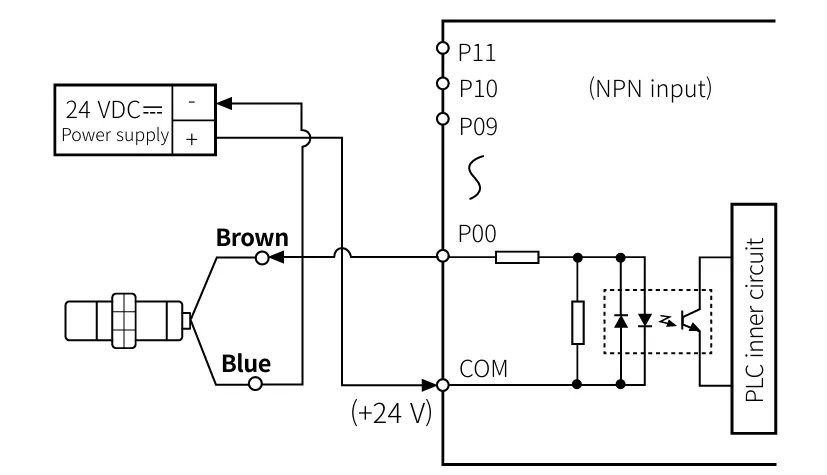

Working Principle of NPN Proximity Sensor

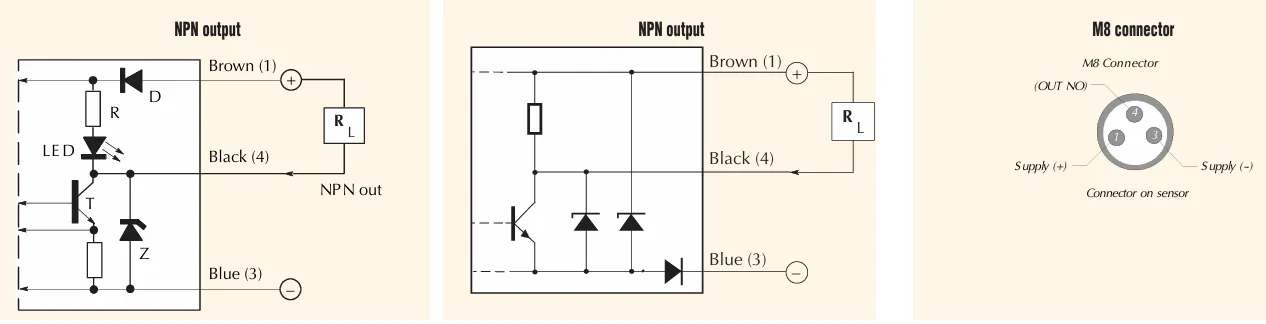

The NPN proximity sensor operates by emitting an electromagnetic field from its sensing face. When a target object enters this field, it disturbs the field, and the sensor detects this change. The internal transistor turns ON, pulling the output to ground (0V), which allows the input device (PLC or relay) to sense a logic LOW signal. NPN sensors generally have three wires: power supply (+V), ground (0V), and signal output.

Applications of NPN Proximity Sensors

NPN sensors are commonly used in:

- Industrial automation systems

- Material handling and conveyor equipment

- Robotic detection systems

- Sensor networks in PLC control panels

- High-speed metal detection systems

Properties of NPN Proximity Sensors

General technical features of NPN proximity switches include:

- Sensing Range: 2 mm to 15 mm depending on type and target

- Operating Voltage: 10–30V DC

- Output Type: NPN (sinking) – available as Normally Open (NO) or Normally Closed (NC)

- Switching Frequency: Up to 2 kHz for high-speed detection

- Target Material: Best suited for ferrous metals

- Environmental Protection: IP67 (in most industrial-grade sensors)

What is a 2-Wire NPN Sensor?

A 2-wire NPN proximity sensor integrates power and signal lines into just two wires. This compact wiring design can simplify installation but may have limitations in terms of current handling and load compatibility. It connects directly in line with the load and typically requires matching with specific input circuitry.

What is a 3-Wire NPN Sensor?

The 3-wire NPN sensor is the standard configuration used in industrial control. It includes:

- Brown: +V DC supply (typically 24V)

- Blue: 0V (Ground)

- Black: Output signal (sinking to 0V when active)

What is the difference between NPN and PNP proximity sensors?

The main difference between NPN and PNP proximity sensors lies in their output switching method. An NPN sensor (also called a sinking sensor) switches the connection to ground (0V) when activated, while a PNP sensor (also called a sourcing sensor) switches the connection to the positive supply voltage (+V). In NPN sensors, the load is connected between the sensor output and the positive terminal, whereas in PNP sensors, the load is connected between the output and the negative terminal. NPN is commonly used in Japanese and American systems, while PNP is popular in European automation systems. Choosing between PNP and NPN depends on the PLC input module type and system wiring requirements.

| Parameter | NPN Proximity Sensor | PNP Proximity Sensor |

|---|---|---|

| Output Type | Sinking (connects to 0V when active) | Sourcing (connects to +V when active) |

| Load Connection | Between output and positive supply | Between output and ground |

| Logic Level When Activated | Low (0V) | High (+V) |

| Preferred Region | Japan, USA | Europe |

| PLC Compatibility | Requires sinking-type PLC input | Requires sourcing-type PLC input |

| Wiring Polarity | Connects negative to load | Connects positive to load |

| Common Use | Industrial control panels (some Asian standards) | Widely used in European automation systems |