Delta PLC Counter Instructions: Low-Speed CNT and High-Speed DCNT

Published on Jun 3, 2025 | Category: CounterShare this Page:

In PLC programming, a counter is an instruction used to count events based on input signals. A counter operates by detecting a transition of an input bit from OFF to ON (i.e., from low to high). Each time this transition occurs, the counter either increments or decrements its present value by one.

Counters are assigned to specific addresses such as C0, C1, C2, and so on, where the letter 'C' denotes that it is a counter, and the numerical part specifies the unique device address. Each counter must be properly addressed to function correctly within the PLC program.

In this article, we focus on how counters are implemented and configured using Delta PLC’s WPLSoft programming software. The software allows users to define counters, set preset values, and monitor the current value as the counter operates during runtime.

It is important to note that the number of available counters in a PLC is limited by the hardware, and the exact range of usable counter addresses depends on the specific PLC model. For instance, some Delta PLC models may support counters ranging from C0 to C255, while others may offer a different range. Therefore, it is always recommended to refer to the official user manual of the particular Delta PLC you are using to verify the valid range and limitations of counters.

In practical applications, counters are widely used in automation systems to count parts, limit cycles, control batch processes, and trigger actions after a specific number of operations. Proper configuration and understanding of counters is essential for building reliable and efficient ladder logic programs.in this article we discuss only low speed counter

how many types of counter available in delta plc

Counters are essential instructions in Delta PLC programming used to count occurrences of input signal transitions. Delta PLC provides two primary types of counter instructions: CNT for low-speed counting and DCNT for high-speed counting. These counters are widely used in industrial automation to monitor pulses, production counts, or timed sequences. This article explains the working, differences, and applications of CNT and DCNT counters in Delta PLCs.delta plc have two type of counter available 16bit and 32 bit counter but these counter further classified as up counter, updown counter and latched counter.

ES/EX/SS Series MPU – Counter C

- 16-bit Counting Up (General Purpose)

- Address Range: C0 ~ C111 (112 points)

- Fixed to be non-latched

- 16-bit Counting Up (Latched)

- Address Range: C112 ~ C127 (16 points)

- Fixed to be latched

- 32-bit Counting Up/Down High-Speed Counter (1-phase 1 input)

- Address Range: C235 ~ C238, C241, C242, C244 (7 points)

- Fixed to be latched

- 32-bit Counting Up/Down High-Speed Counter (1-phase 2 inputs)

- Address Range: C246, C247, C249 (3 points)

- Fixed to be latched

- 32-bit Counting Up/Down High-Speed Counter (2-phase 2 inputs)

- Address Range: C251, C252, C254 (3 points)

- Fixed to be latched

- Total Counter Points: 141

SA/SX/SC Series MPU – Counter C

- 16-bit Counting Up (General Purpose)

- Address Range: C0 ~ C95 (96 points)

- Fixed to be non-latched

- 16-bit Counting Up (Latched)

- Address Range: C96 ~ C199 (104 points)

- Can be modified to be non-latched via parameter settings

- 32-bit Counting Up/Down (General Purpose)

- Address Range: C200 ~ C215 (16 points)

- Fixed to be non-latched

- 32-bit Counting Up/Down (Latched)

- Address Range: C216 ~ C234 (19 points)

- Can be modified to be non-latched via parameter settings

- High-Speed Counter (SA/SX)

- 1-phase 1 input (Latched): C235 ~ C242, C244 (9 points)

- 1-phase 2 inputs (Latched): C246, C247, C249 (3 points)

- 2-phase 2 inputs (Latched): C251 ~ C254 (4 points)

- Total High-Speed Points: 16

- High-Speed Counter (SC Series)

- 1-phase 1 input (Latched): C235 ~ C245 (11 points)

- 1-phase 2 inputs (Latched): C246 ~ C250 (4 points)

- 2-phase 2 inputs (Latched): C251 ~ C255 (4 points)

- Can be modified to be non-latched via parameters

- Total High-Speed Points: 19

- Total Counter Points (SA/SX/SC): 235

EH/EH2/SV Series MPU – Counter C

- 16-bit Counting Up (General Purpose)

- Address Range: C0 ~ C99 (100 points)

- Can be modified to be latched via parameters

- 16-bit Counting Up (Latched)

- Address Range: C100 ~ C199 (100 points)

- Can be modified to be non-latched via parameters

- 32-bit Counting Up/Down (General Purpose)

- Address Range: C200 ~ C219 (20 points)

- Can be modified to be latched via parameters

- 32-bit Counting Up/Down (Latched)

- Address Range: C220 ~ C234 (15 points)

- Can be modified to be non-latched via parameters

- Software High-Speed Counter

- 1-phase 1 input: C235 ~ C240 (6 points)

- Hardware High-Speed Counter

- 1-phase 1 input: C241 ~ C244 (4 points)

- 1-phase 2 inputs: C246 ~ C249 (4 points)

- 2-phase 2 inputs: C251 ~ C254 (4 points)

delta plc Low-Speed Counter CNT

- The CNT instruction is used for counting rising edge signals from input contacts at a standard (low) speed.

- It is suitable for applications where the input signal does not change too rapidly (e.g., button press, sensor trigger).

- Each time the input coil transitions from OFF to ON, the counter increments by 1.

- The current count is stored in a counter address (e.g., C0, C1, ...).

- When the counter reaches the preset value (PV), its done bit (Y coil) is turned ON.

- Can be reset using a dedicated reset coil (RST C0).

delta plc High-Speed Counter DCNT

- The DCNT instruction is designed for high-frequency pulse counting directly from the hardware input channels.

- Useful for applications such as rotary encoders, flow meters, and proximity sensors with fast pulse rates.

- DCNT supports counting modes such as up, down, or up/down counting depending on hardware wiring.

- It uses high-speed input terminals (X0 ~ X3) on supported MPUs (such as ES, EX, SS, EH series).

- DCNT counters use dedicated device numbers like C235 to C255 depending on the PLC model.

- Can handle frequencies up to several kHz (model-dependent).

- Parameters such as count mode, edge trigger, and initial value are configured via system settings or ladder logic.

What is a 16-bit and 32-bit Counter and Its Important Role

In Delta PLC programming, counters are categorized based on the bit-length of their data handling capacity, typically as 16-bit and 32-bit counters. A 16-bit counter can represent values from 0 to 32,767 and is generally used for general-purpose counting in a single direction (counting up). On the other hand, a 32-bit counter can handle much larger ranges, from -2,147,483,648 to +2,147,483,647, and is capable of counting in both directions—up and down, making it suitable for high-speed and precision applications.

The Set Value (SV) for both counter types can be defined using a constant (K) or a data register (D). In 32-bit counters, two values may be designated to define the full range accurately. The Present Value (PV) in a 16-bit counter stops counting once the SV is reached, while a 32-bit counter continues counting even after the SV is reached, providing flexibility for bi-directional counting logic.

Regarding execution timing, both counter types act upon scan completion in software-based execution. However, in high-speed counters (32-bit), especially when hardware-based, contact action occurs immediately when the target count is reached, regardless of the scan cycle. This makes 32-bit counters ideal for time-sensitive operations such as encoder pulse counting or rapid input detection, playing a crucial role in precise industrial automation tasks.

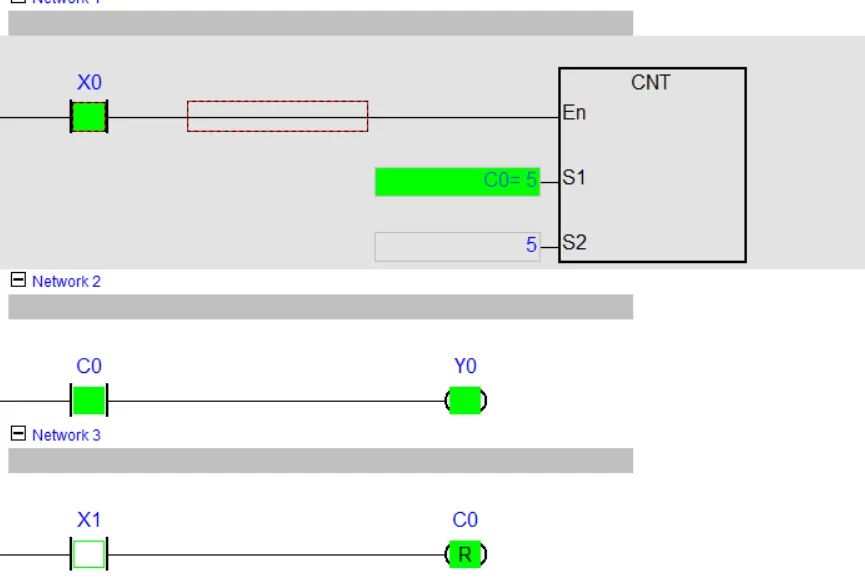

CNT Instruction: 16-bit Up Counter in Delta PLC

The CNT instruction in Delta PLC is a 16-bit up counter used to count rising edge signals from input contacts. Each time the counter input changes from LOW to HIGH (OFF to ON), the counter increments its Present Value (PV) by 1. When the Present Value becomes equal to the Preset Value (SV), the counter stops incrementing, even if further input transitions occur. This ensures the counter only counts up to its defined setpoint.

If the counter's output bit is already ON, no further counting occurs. To reset the counter, the RST (reset) instruction must be used with the associated counter number. The Preset Value (SV) is a numerical word-type value and can be defined using a constant (K), a data register (D), or any word-based value. The valid range for a 16-bit counter is K0 to K32,767, where K0 is functionally treated the same as K1.

Notably, the counter’s output contact turns ON immediately when the first count is registered. Since this is a 16-bit general-purpose counter, its Present Value (PV) is cleared when the PLC is powered off. However, if the counter is configured as a latched type, it will retain the Present Value and output status even after a power cycle, allowing it to resume counting from where it left off once the power is restored.

In Delta DVP-PLC systems, counters like CNT play a vital role in monitoring discrete input events, such as item counting, process tracking, or cycle monitoring, with precise behavior and flexible configuration based on application needs.

DCNT Instruction: 32-bit General Purpose Counter in Delta PLC

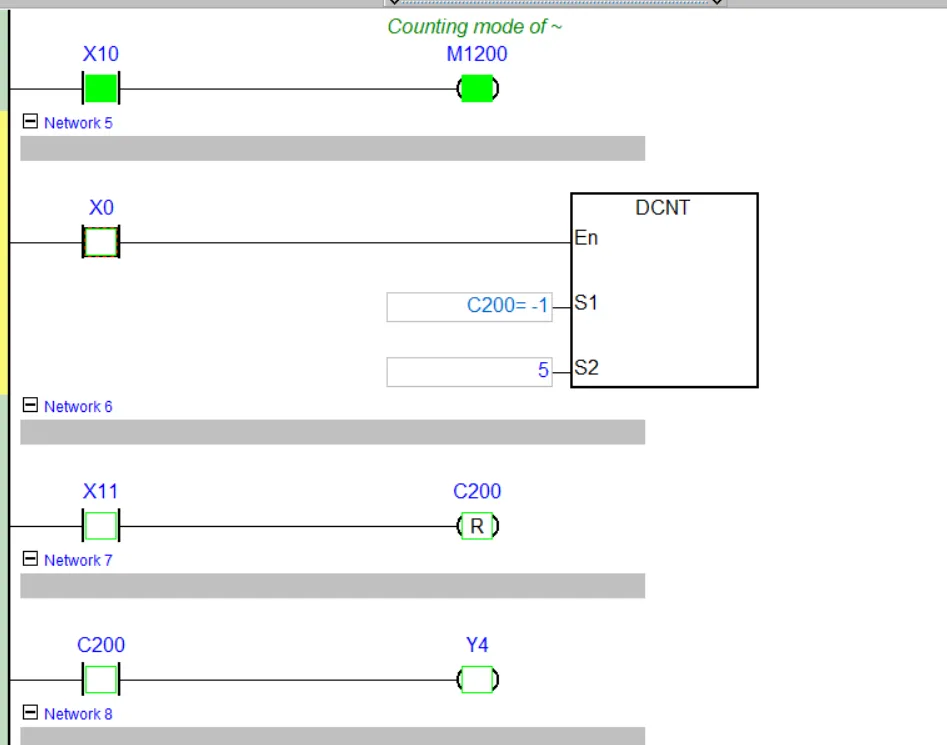

The DCNT instruction in Delta PLC is a 32-bit general-purpose counter that supports both up-counting and down-counting operations. This makes it highly suitable for advanced automation applications where bidirectional counting is required. Unlike the standard 16-bit CNT instruction, the DCNT provides an extended value range and direction control through auxiliary relays.

The valid setup range for a 32-bit counter is from K–2,147,483,648 to K+2,147,483,647, allowing a much wider numerical scope for counting large-scale events or high-resolution encoder pulses. This extended range enables the DCNT instruction to handle both small and large-scale industrial tasks with high precision. Note: DCNT counters are not available for ES, EX, or SS series MPUs.

The direction of the count—whether to increment (count up) or decrement (count down)—is determined by the status of special auxiliary relays M1200 to M1234. Each 32-bit counter (e.g., C200 to C234) is paired with a corresponding M bit to define its counting mode. For example:

If M1200 = OFF, the associated counter C200 will function as an up counter. If M1200 = ON, C200 will operate as a down counter. This method allows dynamic control over counter behavior based on logic conditions within the program.

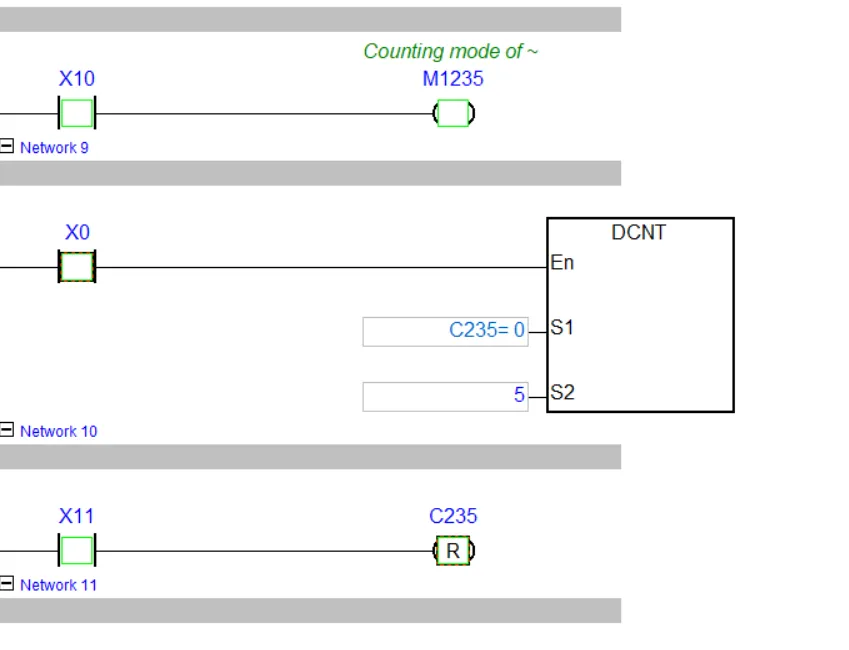

DCNT Instruction: 32-bit High Speed Counter in Delta PLC

The DCNT (Double-word Count) instruction is used for high-speed, 32-bit counting in Delta PLCs. It supports both up-counting and down-counting based on the ON/OFF state of special auxiliary relays, with an extremely large counting range of K-2,147,483,648 to K+2,147,483,647.

For high-speed counters like C235 ~ C244, counting direction is controlled by the ON/OFF state of relays M1235 ~ M1244:

- If M1235 is OFF, C235 counts up.

- If M1235 is ON, C235 counts down.

Similarly, counters C246 ~ C255 are controlled via M1246 ~ M1255:

- M1246 = OFF → C246 counts up.

- M1246 = ON → C246 counts down.

The Set Value (SV) can be specified using:

- A constant value K (e.g., K100)

- A data register D (excluding D1000 ~ D1999)

The DCNT counter retains the advantages of 32-bit data handling, supporting accurate control in high-speed counting scenarios or where large ranges are essential. It is especially useful in applications such as encoder pulse tracking, bidirectional conveyor systems, or motion control loops.

Understanding the difference between CNT and DCNT instructions is crucial for efficient Delta PLC programming. Use CNT for standard counting needs and DCNT for precise, real-time high-speed pulse counting. Always refer to the specific PLC series manual to understand address ranges and performance limitations for counter instructions.