FactoryTalk View SE Data Logging

Published on May18, 2025 | Category: introdunctionShare this Page:

Data logging is the process of storing tag values over time in a database or internal file set.

You can use this logged data to monitor and analyze processes, generate reports, track trends, and identify issues or root causes.

FactoryTalk View SE data logging is configured to collect data at specific intervals or in real-time, depending on system requirements.

It allows logging of process variables, HMI tags, alarms, events, and trend data.

This data can be used for real-time visualization, historical trend analysis, performance tracking, or predictive maintenance.

FactoryTalk View SE supports logging to ODBC-compatible databases such as Microsoft SQL Server, as well as to proprietary .DB files.

A data log model in FactoryTalk View SE defines:

– Which tags to log

– When to log the data (rate or event-driven)

– Where to store the data (SQL or local files)

Proper data logging helps improve traceability, process optimization, and quality control in industrial automation systems.

FactoryTalk View Data Log Model

FactoryTalk View Data Log Models are a key component that define how, when, and where process data will be logged. These models allow you to specify the storage format of log files, determine the storage location, and configure whether to use file sets or ODBC databases for data storage. You can also set events or specific time conditions to create and delete files or records. Each data log model can record data for up to 10,000 tags, and 20 data log models can run simultaneously on a single FactoryTalk View SE Server.

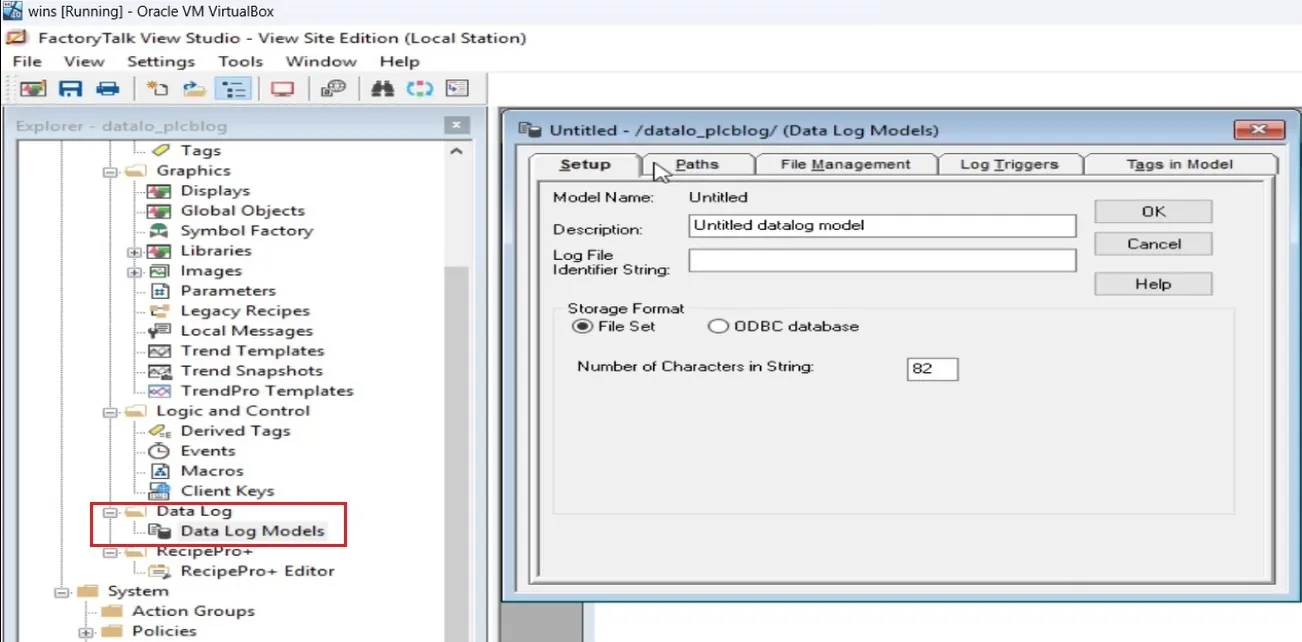

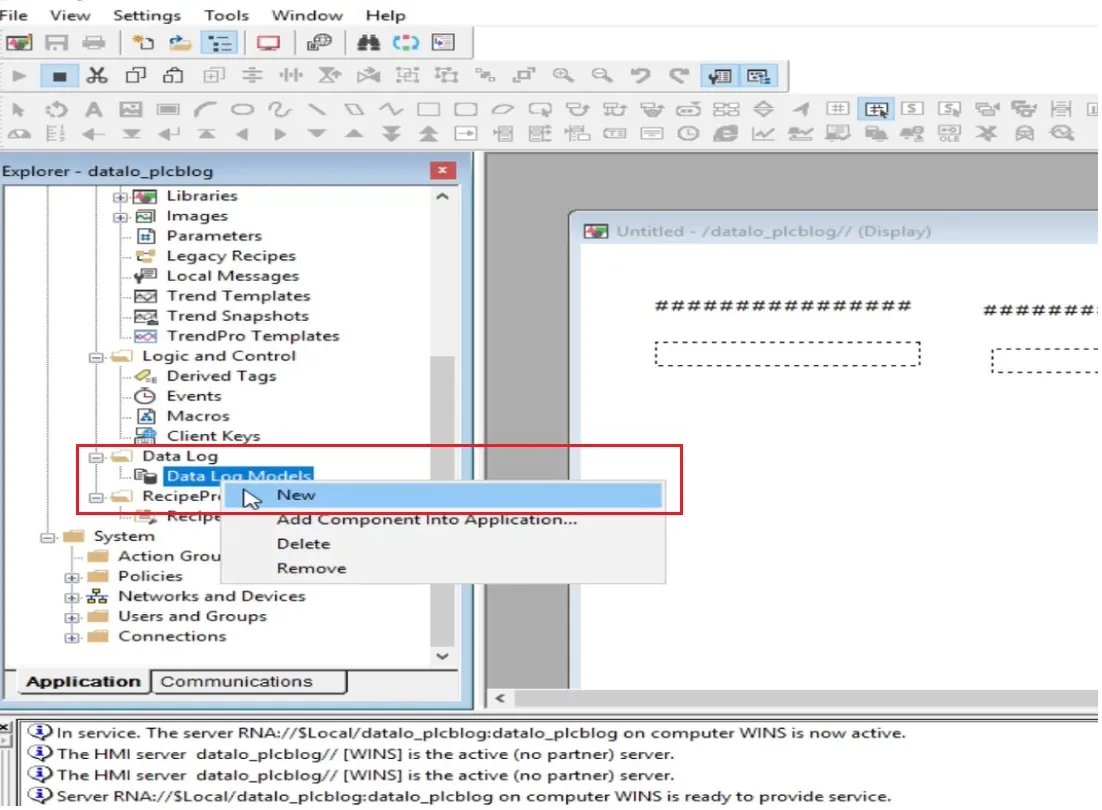

How To Open FactoryTalk View Data Log Model

To open a data log model in FactoryTalk View Studio:

In the Explorer window, expand the Data Log folder.

Right-click Data Log Models, and then select New to create a new model.

Specifying the Storage Format or Type

In the Setup tab of the model, specify the following:

- Log file name: A descriptive name for the log file (used for identification).

- Log file identifier: A string that becomes part of the filename.

- Storage format: Choose between File Set or ODBC database. For this example, we use File Set.

- Character length: If logging string tags, specify max character length.

We are using data logging for a blower motor application and configuring the fields accordingly.

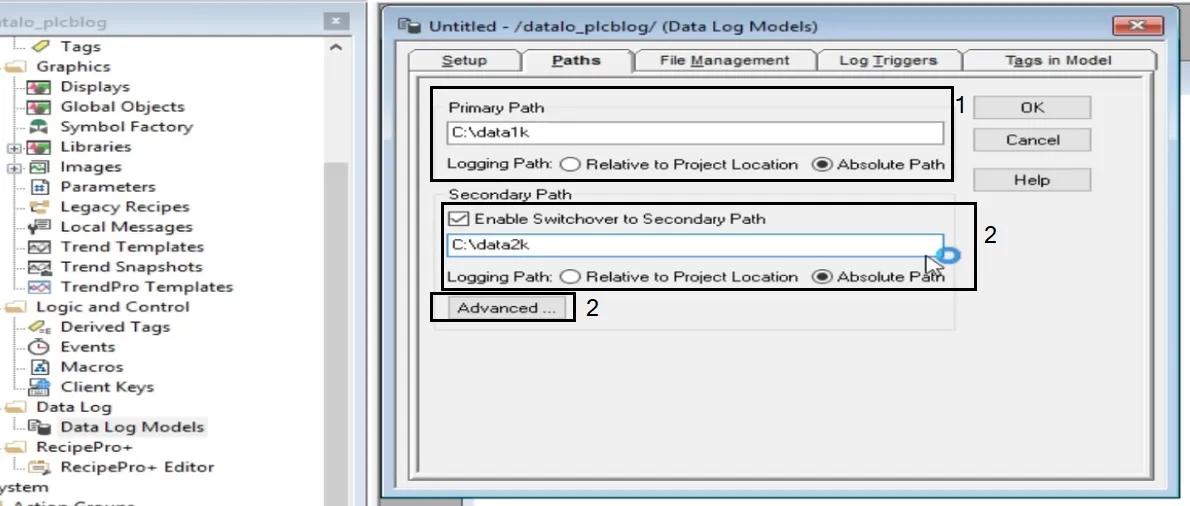

Set Up Log Paths

Use the Paths tab to define log file locations:

- Primary path: Main folder to store logs. Default is relative to the project. You may choose an absolute path if needed.

- Secondary path: Optional backup location if the primary becomes full or unavailable.

- Advanced options: Define the switchover time between primary and secondary paths.

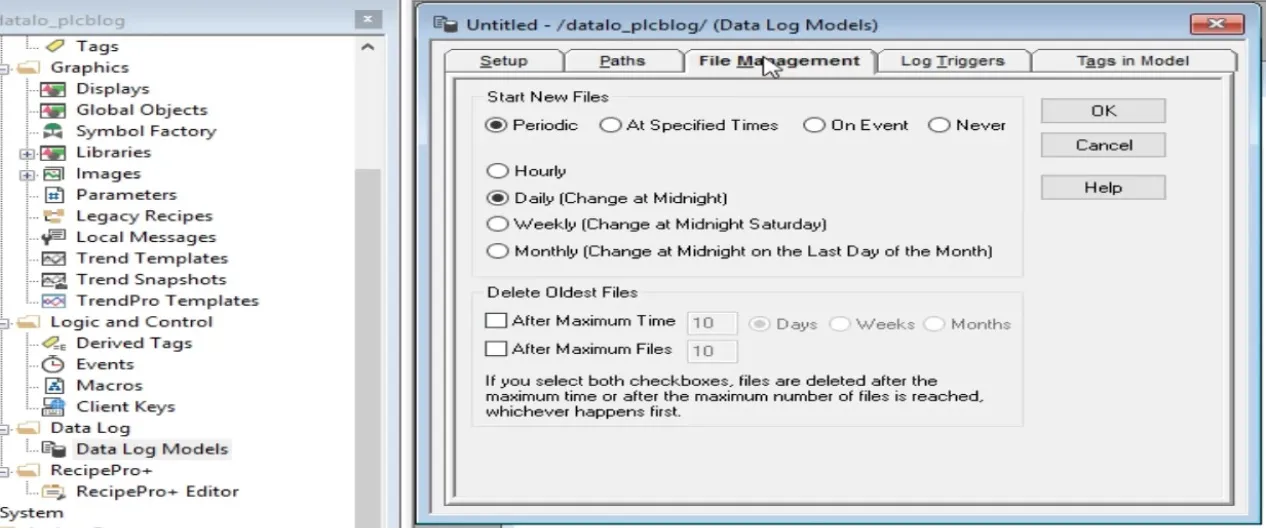

Managing Data Log Files and Creating File Sets

In the File Management tab:

- Start New Files: Choose when to create new files (periodically, at specific times, on event, or never).

- Delete Old Files: Set to delete old logs after a time limit or max number of file sets. You can uncheck this option to retain all files.

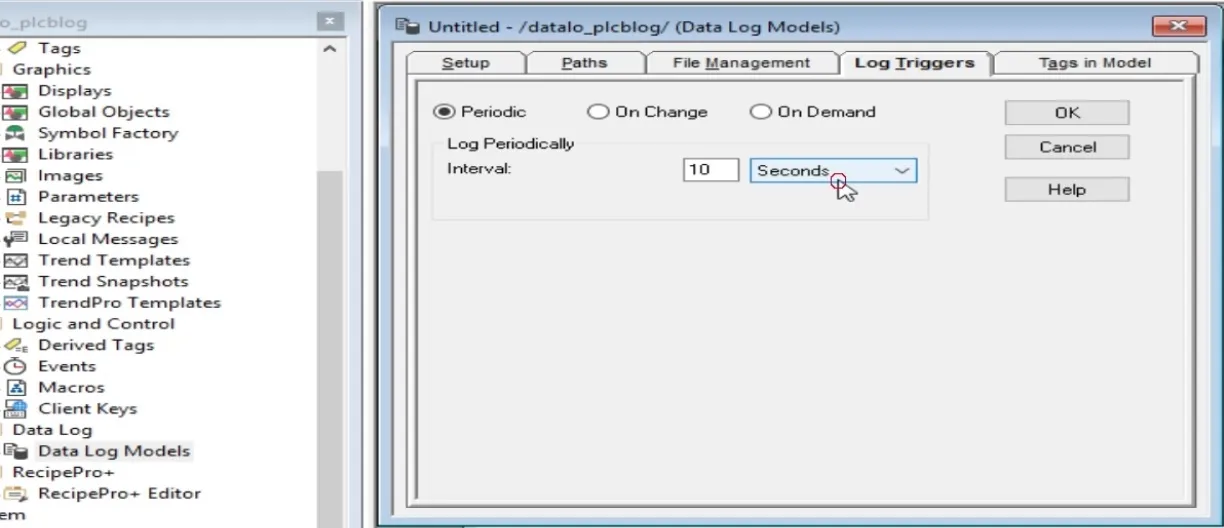

Specifying When to Log Data

Use the Log Triggers tab to choose how data is logged:

- Periodically: Logs at regular intervals (e.g., every 10 seconds).

- On Change: Logs only when tag values change.

- On Demand: Logs when a specific event occurs using the DataLogSnapshot command.

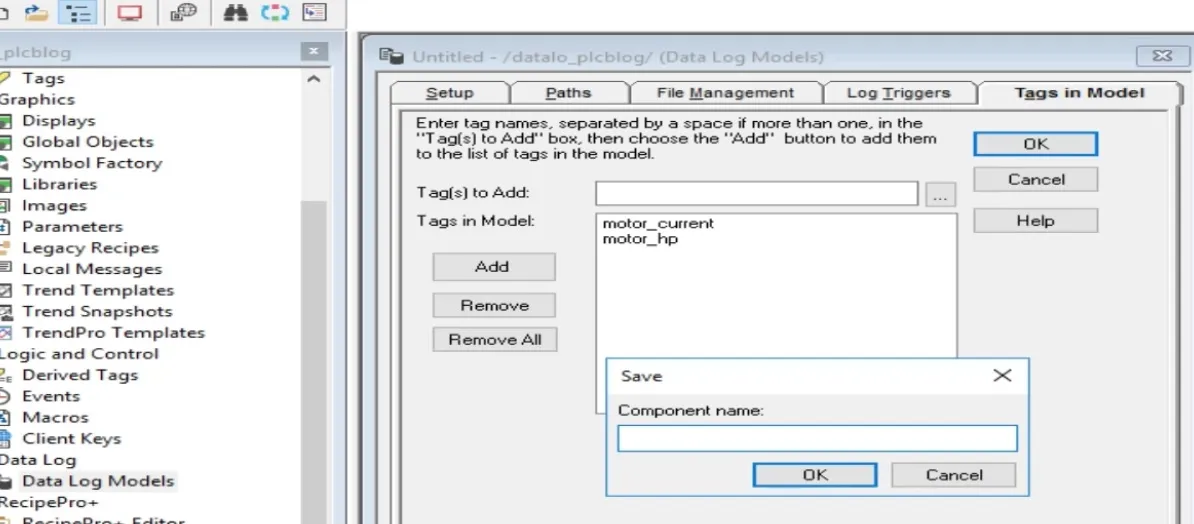

Select Tags for Data Logging

In the Tags in Model tab, add the tags to be logged. A model can include up to 10,000 tags. Tags can be digital, analog, string, or derived values. Browse and select tags to include in your model.

Set Component Name for the Data Log Model

After completing the setup, click OK and give a name to your data log model component. This name will be used when referencing the model in commands or automation scripts.

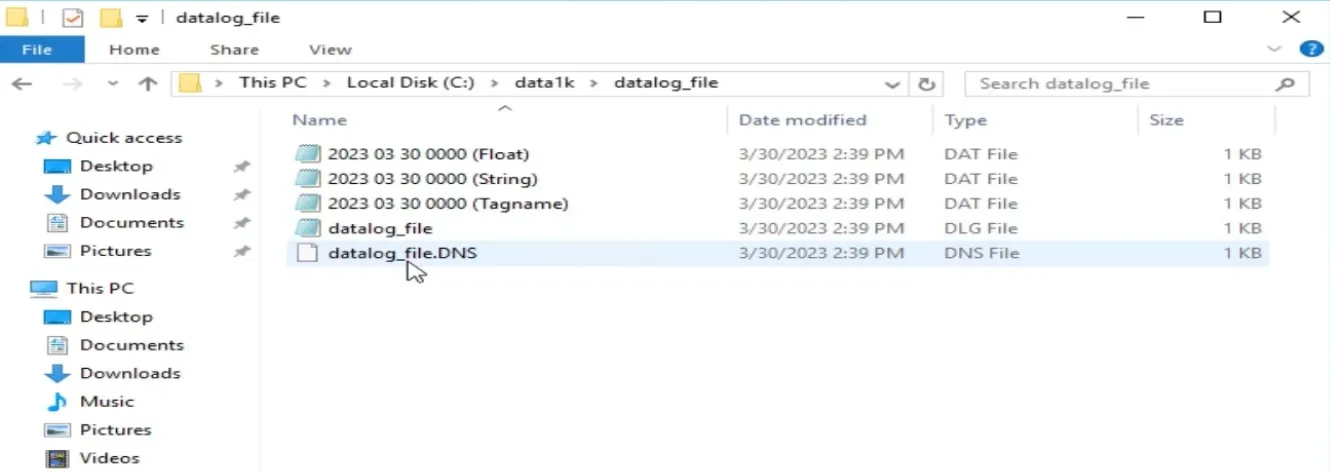

Starting Data Logging in FactoryTalk View

To start logging, use any of the following methods:

- Use the command line: DataLogOn 'datalog_file'

- Enable it via the HMI Server Properties > Components tab.

- Right-click the data log model component and select Start.

You can also assign the start command to a button, event, or macro for dynamic control.

Once logging starts, FactoryTalk View SE automatically creates log files in your defined primary folder according to your configuration.

Stopping Data Logging

To stop logging, use any of the following options:

- Use the command line: DataLogOff 'datalog_file'

- Right-click the data log model component and choose Stop.

This stops recording data until logging is started again manually or automatically.