Pressure Switch – Working Principle, Types, Diagram, and Applications

Published on July 23, 2024 | Category: introductionShare this Page:

A pressure switch is an electromechanical device used to monitor the pressure of gases or liquids and connect or disconnect an electrical circuit based on a predefined setpoint. It plays a vital role in industrial automation, safety systems, and equipment protection. When the system pressure reaches a specific level, the switch opens or closes the circuit to trigger alarms, control pumps, activate compressors, or shut down machinery. Common examples include water pump systems (where the switch turns the pump off at high pressure and on at low pressure), air compressor cutoff controls, and fire suppression systems that monitor fluid or gas pressure. Pressure switches come in various types, such as mechanical, diaphragm-operated, piston-type, and modern electronic switches with digital outputs. A pressure switch can also function as a control unit or serve as an optical or acoustic monitor or indicator.

These pressure switches are durable and reliable gauge-based electromechanical devices, available in configurations such as single pole single throw (SPST) — normally open (NO) or normally closed (NC) — and single pole double throw (SPDT) circuitry. Their high proof pressure and burst pressure ratings make them suitable for rugged applications that require making or breaking an electrical connection in response to pressure changes in the system media. This page provides a complete guide to how pressure switches work, the different types available, wiring diagrams, key applications, comparisons with pressure transmitters, and practical troubleshooting tips for maintenance and safety.

What is a Pressure Switch?

A pressure switch is an electromechanical device that detects the pressure level of a gas or liquid in a system and responds by opening or closing an electrical contact. It operates based on a preset pressure threshold—activating or deactivating equipment when the pressure goes above or below that setpoint. Pressure switches are widely used in industrial and commercial systems for automation, safety, and control.

For example, in a water pump system, the switch turns the pump off when the tank reaches high pressure and turns it back on when pressure drops. Other typical uses include air compressor shutdowns, HVAC monitoring, hydraulic systems, and fire suppression systems. Pressure switches are available in various types, including mechanical, diaphragm-type, and electronic switches with digital output.

Types of Pressure Switches

Pressure switches come in various types based on their sensing mechanism, switching action, and application requirements. Below are the most common types:

- Mechanical Pressure Switch: Uses a spring-loaded mechanism or diaphragm to actuate the switch. It is widely used in general industrial and pump control applications.

- Electronic Pressure Switch: Uses pressure sensors and electronic circuitry to measure pressure and trigger switching. These are highly accurate and often include digital displays and programmable settings.

- Diaphragm-Type Pressure Switch: Uses a flexible diaphragm to sense pressure changes. Ideal for low-pressure applications and compatible with corrosive or sensitive media.

- Piston-Type Pressure Switch: Uses a piston mechanism for sensing and switching. It is suitable for higher pressure ranges and dirty fluids.

- Differential Pressure Switch: Measures the difference in pressure between two points. Commonly used in filter monitoring, flow measurement, and pump protection.

- Vacuum Pressure Switch: Activates or deactivates circuits when vacuum levels fall below or rise above a specific threshold. Useful in vacuum pumps and suction lines.

- SPST / SPDT Pressure Switch: Refers to the switching configuration — Single Pole Single Throw (normally open or normally closed) and Single Pole Double Throw — depending on the control requirement.

Each type of pressure switch is selected based on the application environment, media compatibility, pressure range, and control system requirements.

Working, Components, and Operation of Pressure Switch

A pressure switch works by detecting changes in pressure and activating or deactivating an electrical circuit when a setpoint is reached. The basic operation is mechanical or electronic, depending on the type. The switch is designed to respond to either a rise or fall in pressure in a system — commonly found in pumps, compressors, hydraulic systems, and industrial automation setups.

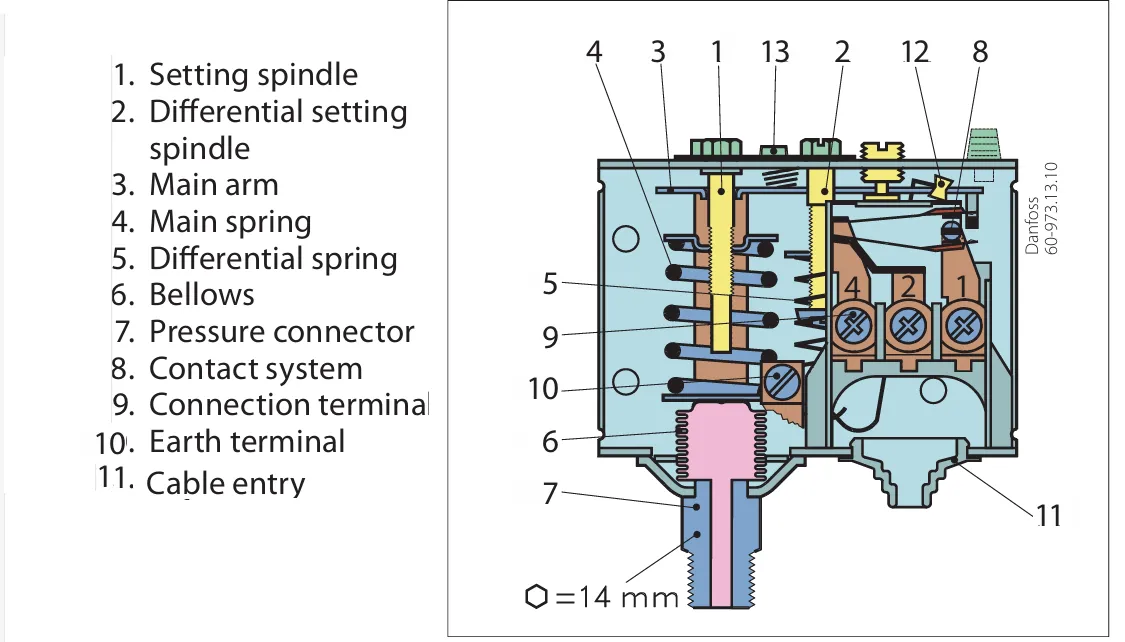

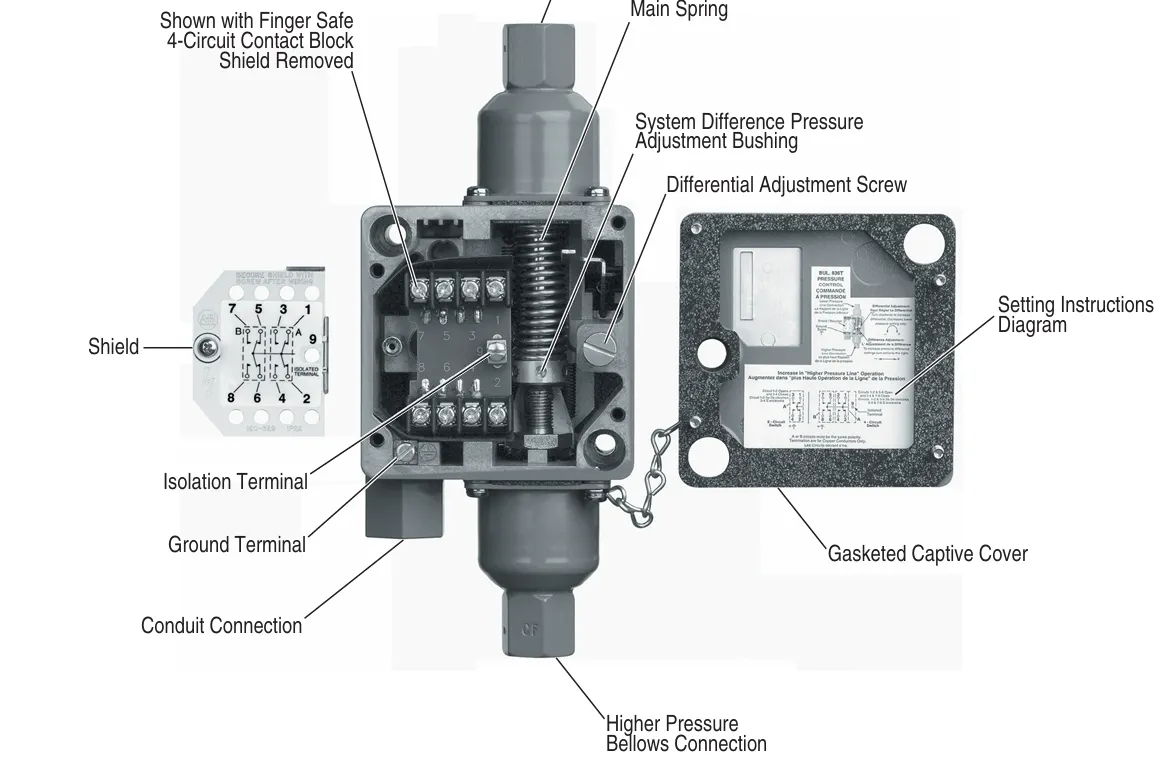

Key Components of a Pressure Switch:

- Pressure Sensing Element: Typically a diaphragm, piston, or bourdon tube that moves in response to pressure changes.

- Adjustable Spring: Sets the desired pressure setpoint. The spring tension determines at what pressure the switch activates.

- Contact System: Electrical contacts (SPST or SPDT) that open or close the circuit when actuated.

- Housing/Enclosure: Protects the internal components from dust, moisture, and mechanical damage.

How It Operates:

When the process pressure increases and reaches the setpoint, the sensing element deflects and pushes against the spring-loaded mechanism. This causes the contacts to either open or close, depending on whether it is normally open (NO) or normally closed (NC). Once the pressure drops back below the reset point (known as the differential), the contacts return to their original position.

In electronic pressure switches, a pressure transducer converts the pressure signal into an electrical signal, which is then processed digitally to trigger output signals, alarms, or control functions.

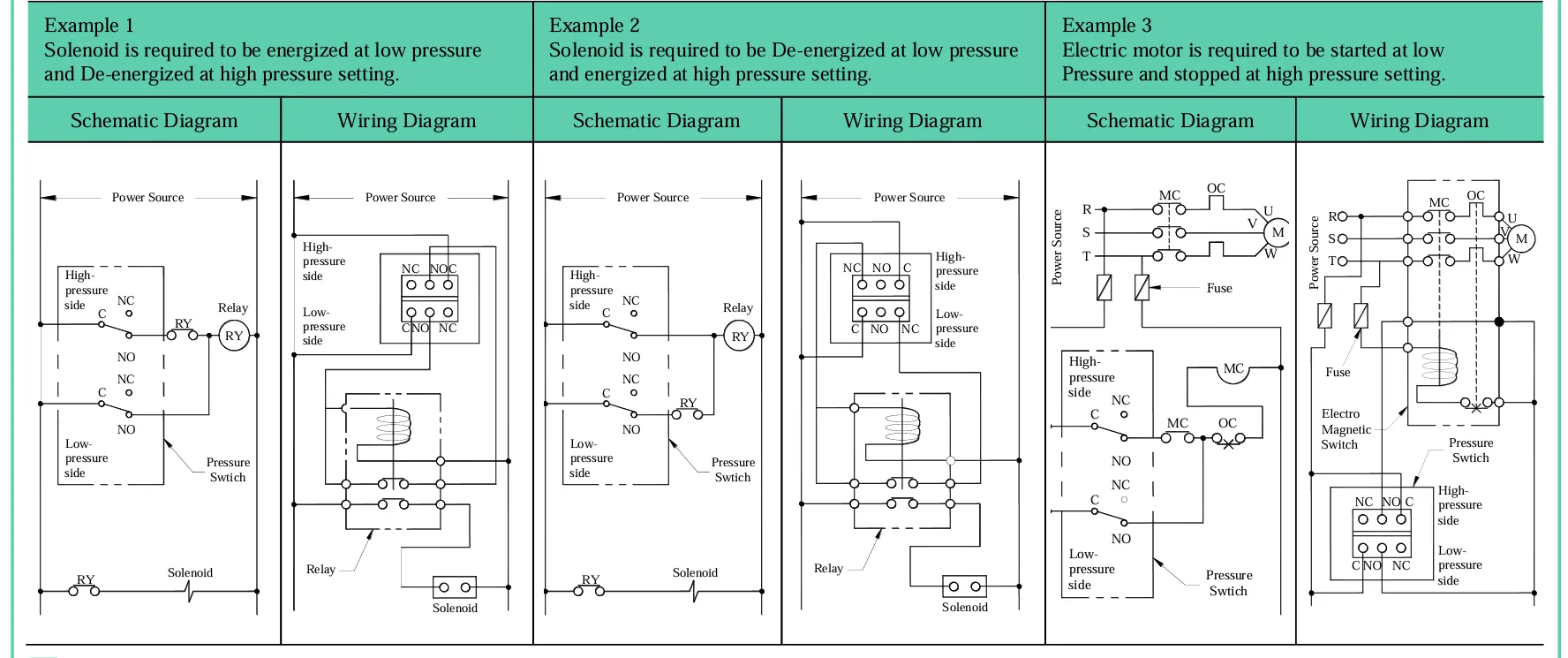

Wiring and Connection Diagram of Pressure Switch

Wiring a pressure switch depends on its internal contact configuration (SPST or SPDT) and the application (pump control, alarm triggering, etc.). A basic pressure switch has two or three terminals, and the electrical connection either completes or interrupts a circuit based on system pressure.

Common Wiring Terminals:

- Common (C): The terminal that connects to either NO or NC contact depending on the switch condition.

- Normally Open (NO): The contact remains open when the pressure is below the setpoint and closes when pressure increases.

- Normally Closed (NC): The contact remains closed when the pressure is below the setpoint and opens when pressure increases.

Typical Wiring Example:

In a pump control application, the pressure switch is connected in series with the control circuit of the motor. When the pressure drops below the setpoint, the NO contact closes, completing the circuit and starting the pump. When the pressure rises above the cut-off limit, the contact opens and stops the pump.

SPDT switches offer more flexibility by providing both NO and NC options in a single unit, allowing for control and feedback circuits simultaneously.

Applications of Pressure Switches

Pressure switches are widely used across industrial, commercial, and residential sectors for automation, safety, and process control. Their ability to monitor and respond to pressure changes makes them essential in systems that require precise operation based on pressure thresholds.

Common Applications Include:

- Water Pump Control: Automatically starts or stops pumps based on tank or pipeline pressure levels.

- Air Compressors: Ensures compressors stop at high pressure and restart at low pressure, preventing over-pressurization.

- HVAC Systems: Monitors refrigerant pressure and air flow in heating and cooling units.

- Hydraulic Systems: Maintains operational pressure levels in machinery, preventing pressure overloads.

- Fire Suppression Systems: Detects pressure drops to trigger alarms or start backup pumps.

- Process Industries: Used in oil & gas, chemical, and food processing for pressure-based interlocks and alarms.

- Fuel and Gas Systems: Prevents leaks and ensures proper pressure regulation in pipelines and storage tanks.

The choice of pressure switch depends on the system's pressure range, media type (liquid or gas), response time, and whether analog or digital feedback is needed.

Troubleshooting and Maintenance of Pressure Switches

Regular troubleshooting and maintenance of a pressure switch are essential to ensure safe and reliable operation. Over time, mechanical wear, environmental exposure, or process media contamination can affect switch performance or calibration.

Common Issues and Troubleshooting Tips:

- No Response or Failure to Switch: Check electrical connections, terminal tightness, and power supply. Replace damaged contacts or fuses.

- Inaccurate Switching: Verify the setpoint and recalibrate if needed. Mechanical components may require adjustment or replacement.

- Frequent On-Off Cycling: This may indicate a small pressure differential setting. Increase the differential range or inspect system pressure stability.

- Pressure Switch Leaks: Inspect the diaphragm, seals, or housing for signs of wear or corrosion. Replace faulty parts promptly.

- Wiring Faults: Check for loose terminals, corroded contacts, or short circuits in the control wiring.

Maintenance Best Practices:

- Periodically clean the switch body and sensing elements to prevent clogging.

- Test the switching action regularly under controlled conditions.

- Inspect gaskets and enclosures to prevent moisture ingress or dust accumulation.

- Record calibration and inspection dates as part of preventive maintenance schedules.

Timely maintenance not only ensures the long-term accuracy of pressure switches but also enhances process safety, reduces downtime, and extends equipment lifespan.

Difference Between Pressure Switch and Pressure Transmitter

Both pressure switches and pressure transmitters are used to monitor system pressure, but they operate differently and serve different functions in automation and control systems.

| Parameter | Pressure Switch | Pressure Transmitter |

|---|---|---|

| Function | On/Off switching based on pressure setpoint | Continuous analog output (e.g., 4–20 mA) proportional to pressure |

| Output Type | Discrete (digital) signal | Analog or digital (continuous pressure data) |

| Accuracy | Moderate | High |

| Usage | Simple control or alarm systems | Precise pressure monitoring, feedback, and process control |

| Complexity | Simple device, easy to install | More complex, often needs calibration and configuration |

| Cost | Lower | Higher |

In summary, pressure switches are ideal for threshold-based control, while pressure transmitters are preferred in applications requiring real-time monitoring, analog control, and precise measurement.

Switching Function of a Pressure Switch

The switching function of a pressure switch refers to its ability to open or close an electrical circuit in response to a change in pressure. This function is essential for automating control processes, activating alarms, or protecting equipment in both low and high-pressure scenarios.

How Switching Works:

When the system pressure reaches a preset value (setpoint), the pressure sensing element — such as a diaphragm or piston — deflects and activates the internal switching mechanism. Depending on the design, the switch can be:

- Normally Open (NO): Circuit remains open under normal conditions and closes when the pressure exceeds the setpoint.

- Normally Closed (NC): Circuit remains closed under normal conditions and opens when the pressure exceeds the setpoint.

- Single Pole Double Throw (SPDT): Offers both NO and NC outputs, allowing the user to choose the appropriate output for control or feedback.

for example In a pump system using a normally open pressure switch, the switch closes when pressure drops below the setpoint, starting the pump. Once the desired pressure is reached, the switch opens and stops the pump. This prevents over-pressurization and automates fluid handling efficiently.

Pressure Range – What is Pressure Range and How to Set It

The pressure range of a pressure switch defines the minimum and maximum pressure values within which the switch can operate safely and accurately. It represents the span of pressure over which the switch can be adjusted to activate or deactivate a connected electrical circuit.

What is Pressure Range?

For example, if a pressure switch has a range of 2 bar to 10 bar, it means the switch can be set to trigger between these values. Operating it outside this range can lead to inaccurate switching or even mechanical failure. Different applications require different ranges — a pneumatic system may need a low range (0.5–2 bar), while hydraulic systems often operate at higher ranges (20–300 bar).

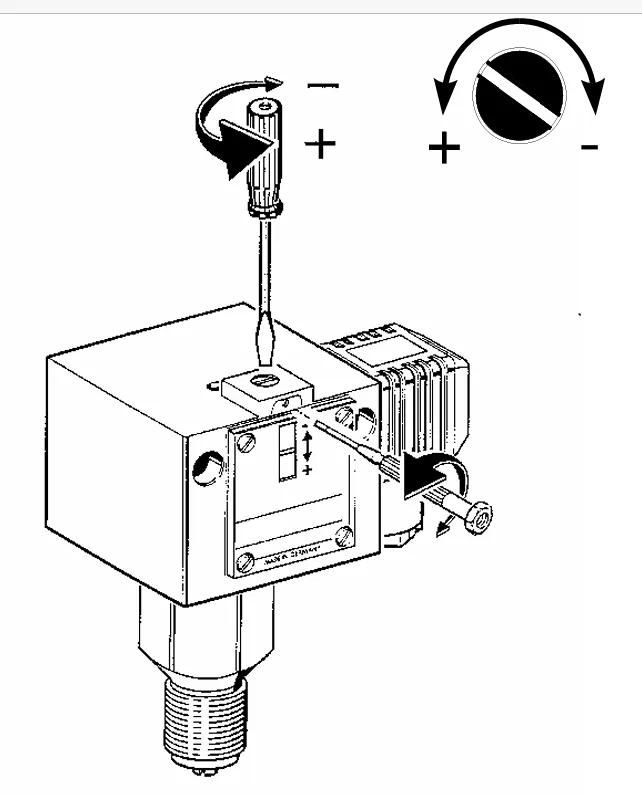

How to Set Pressure Range on a Pressure Switch:

- Identify Setpoint: Determine the pressure at which the switch should activate or deactivate based on your process requirements.

- Adjust Setpoint Screw: Most mechanical switches have a setpoint screw or dial. Turning it clockwise usually increases the setpoint; counterclockwise decreases it.

- Set the Differential (if available): Some switches allow adjusting the differential — the gap between cut-in and cut-out pressures — to prevent rapid cycling.

- Verify with a Gauge: Use a calibrated pressure gauge to ensure accurate settings while testing the system under real conditions.

Always refer to the manufacturer's datasheet to understand the safe pressure range and recommended adjustment procedure for your specific switch model.

High Pressure Switches and Low Pressure Switches

High pressure switches and low pressure switches are specialized types of pressure switches designed to operate at different pressure ranges depending on the system requirements. Both serve similar functions — to monitor pressure and open or close a circuit — but are built with different sensing elements, housing materials, and calibration limits to suit their respective pressure levels.

What is a High Pressure Switch?

A high pressure switch is designed to monitor and control systems operating at high pressure levels, typically above 100 bar and up to several hundred bar. They are used in hydraulic systems, heavy-duty compressors, power plants, and industrial gas systems. These switches are rugged, often piston-actuated, and made from high-strength materials to withstand extreme conditions.

What is a Low Pressure Switch?

A low pressure switch is used in systems where the pressure range is minimal — often less than 10 bar. These are ideal for monitoring pneumatic systems, air filters, vacuum lines, and low-pressure fluid transport. Diaphragm-type sensing elements are commonly used for better sensitivity and accuracy at low pressures.

Comparison:

| Feature | High Pressure Switch | Low Pressure Switch |

|---|---|---|

| Typical Pressure Range | 100 bar to 600+ bar | 0.1 bar to 10 bar |

| Sensing Element | Piston or reinforced diaphragm | Thin diaphragm or capsule |

| Applications | Hydraulics, gas cylinders, high-pressure compressors | Pneumatics, vacuum systems, leak detection |

| Material Strength | High-grade stainless steel, brass | Lightweight plastic, aluminum, or standard steel |

| Cost | Generally higher | Lower and economical |

Choosing between a high or low pressure switch depends entirely on your system’s operating range, required sensitivity, and media compatibility. Always consult datasheets and pressure ratings before selection.