IEC 61131: International Standard for PLCs and Automation Systems

Published on July 16, 2024 | Category: introductionShare this Page:

IEC 61131 is the international standard that defines requirements and guidelines for Programmable Logic Controllers (PLCs) and their programming environments in industrial automation. Issued by the International Electrotechnical Commission (IEC), this standard ensures consistency, compatibility, and reliability across different PLC platforms and software.

The standard is divided into multiple parts:

- IEC 61131-1: General information and definitions related to PLCs

- IEC 61131-2: Hardware requirements and testing

- IEC 61131-3: Programming languages for PLCs (LD, ST, FBD, SFC, IL)

- IEC 61131-4: User guidelines for applying the standard

- IEC 61131-5 and beyond: Communication interfaces, data handling, and extensions

Adoption of IEC 61131 across the industry promotes:

- Standardized software development across PLC brands

- Improved maintenance and troubleshooting

- Interoperability between automation systems

- Faster training and onboarding of engineers

Benefits of IEC 61131 for Users and Programmers

The IEC 61131 standard brings significant advantages to both control system users and automation programmers. It promotes consistent, efficient, and scalable PLC software development across various industries and platforms.

- Reduced Human Resource Waste: The standard minimizes the time and cost involved in training, debugging, system maintenance, and consulting by offering a unified and familiar programming approach across different PLC brands.

- High Level of Software Reusability: By promoting modular programming structures and standard libraries, IEC 61131 allows programmers to reuse code across different projects, reducing development time and ensuring consistency.

- Minimized Errors and Miscommunication: A structured and standardized programming environment reduces misunderstandings among teams and helps avoid costly logic or interface errors during development and commissioning.

- Broad Applicability Across Industries: The techniques and programming models defined by IEC 61131 are applicable in a wide range of industrial automation systems — from manufacturing and process control to building automation and infrastructure.

- Improved System Integration and Collaboration: The standard enables the combination of program components from various sources — including different projects, departments, companies, or countries — simplifying integration and collaborative development.

- Platform Independence and Vendor Neutrality: IEC 61131 allows developers to create applications that are not tied to a specific PLC vendor, making migration, upgrading, or system expansion easier and more cost-effective.

Different Parts of the IEC 61131 Standard

The IEC 61131 standard is not a single document but a series of parts that collectively define the structure, functionality, and development practices for Programmable Logic Controllers (PLCs) in industrial automation. Each part addresses a specific domain such as hardware, programming, communication, and usage guidelines. Here's an overview of the key components:

-

IEC 61131-1: General Information

Describes the basic concepts, definitions, and architectural structure of PLC systems. It sets the foundation for how PLCs should function within control environments. -

IEC 61131-2: Hardware Requirements

Specifies the electrical, mechanical, and environmental conditions PLC hardware must withstand. It includes standards for noise immunity, EMC compliance, and physical durability. -

IEC 61131-3: Programming Languages

This is the most widely adopted part. It defines five standard PLC programming languages — Ladder Diagram (LD), Structured Text (ST), Function Block Diagram (FBD), Sequential Function Chart (SFC), and Instruction List (IL, now deprecated). It enables vendor-independent, reusable, and modular programming. -

IEC 61131-4: User Guidelines

Provides practical implementation and configuration guidelines for applying the standard in automation projects. It helps users design compliant and maintainable systems. -

IEC 61131-5: Communication

Defines how PLCs communicate and integrate with external devices, networks, and control systems. It supports standardized data exchange and interoperability. -

IEC 61131-6 and Future Parts

Covers extended topics such as motion control, safety integration, and object-oriented enhancements for modern PLC platforms. These parts support evolving industrial needs. -

IEC 61131-7: Fuzzy Control Extensions

Introduces fuzzy logic programming capabilities to IEC 61131-compliant systems. It enables more flexible, human-like decision-making for complex control tasks. -

IEC 61131-8: Guidelines for Application and Implementation

Provides best practices and methodologies for implementing PLC-based control systems using IEC 61131 standards effectively in real-world industrial environments. -

IEC 61131-9: IO-Link Communication

Defines IO-Link interface standards for intelligent sensors and actuators, enabling standardized communication and diagnostics at the field device level.

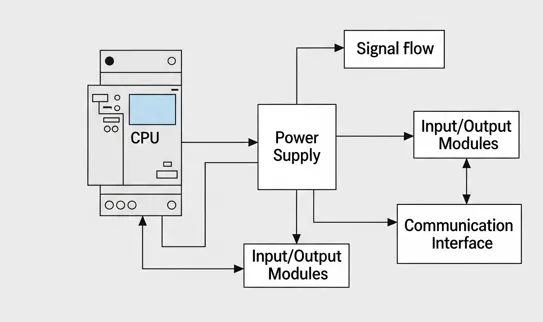

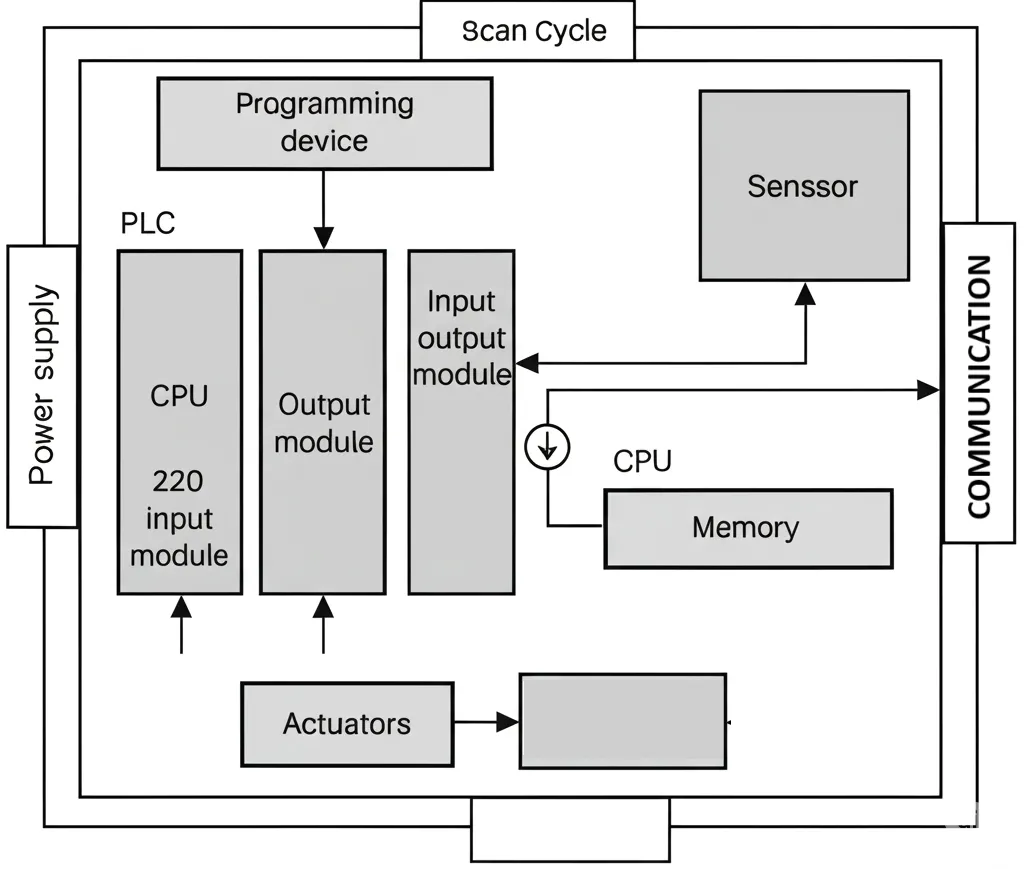

What is IEC 61131-1? – General Information and PLC Architecture

IEC 61131-1 is the first part of the IEC 61131 standard series. It provides the general overview, structure, and essential definitions for Programmable Logic Controllers (PLCs). This part does not focus on programming but rather sets the foundation for how PLCs are defined, categorized, and used in industrial automation.

Here are the key elements defined in IEC 61131-1:

-

1. Definition of a PLC:

A PLC is described as a digital electronic system designed for use in industrial environments, capable of performing logic-based control functions automatically. -

2. Basic Architecture:

It outlines the standard structural components of a PLC system, including:- Central Processing Unit (CPU)

- Input/Output Modules (I/O)

- Memory (for logic and data storage)

- Power Supply

- Communication Interfaces

-

3. Task Types:

Describes the types of execution cycles within a PLC:- Cyclic tasks – run repeatedly at a defined interval

- Event-driven tasks – triggered by specific external or internal events

- Time-driven tasks – executed based on a timer or clock

-

4. System Behavior and Execution:

Specifies how PLCs process inputs, execute control logic, and update outputs in a deterministic and repeatable cycle (scan cycle). -

5. Communication and Interfaces:

Defines how a PLC communicates with field devices, operator panels, and supervisory systems using standard protocols. -

6. Environmental and Operational Considerations:

Sets expectations for reliability and performance in industrial conditions such as temperature, electrical noise, and humidity. -

7. Classification and Functional Role:

Categorizes PLCs based on functionality, size, and application—from small machine control to large process automation systems.

IEC 61131-1 is essential for understanding how PLC systems are structured and what functional blocks they include. It sets the baseline before moving on to programming languages (IEC 61131-3) or hardware testing (IEC 61131-2).

What is IEC 61131-2? – PLC Hardware Requirements and Test Standards

IEC 61131-2 is the second part of the IEC 61131 standard and defines the hardware requirements, performance criteria, and testing methods for Programmable Logic Controllers (PLCs) and their associated input/output devices. This part ensures that PLC hardware can operate reliably under various industrial conditions.

It focuses on standardizing the physical, electrical, and environmental aspects of PLC systems so that devices from different manufacturers can meet minimum safety and performance benchmarks.

-

1. Electrical Characteristics:

Specifies voltage ranges, power supply limits, input/output signal levels, and insulation resistance that PLC hardware must support. -

2. Environmental Conditions:

Defines acceptable operating conditions such as temperature, humidity, vibration, and mechanical shock that the PLC must withstand in industrial settings. -

3. EMC (Electromagnetic Compatibility):

Sets immunity levels against electromagnetic interference (EMI) and defines emission limits to ensure the PLC does not disturb other equipment. -

4. Safety and Isolation Requirements:

Includes safety rules for electrical isolation between control circuits, I/O channels, and external systems, preventing faults and hazards. -

5. Type Tests and Performance Testing:

Specifies standard tests like dielectric withstand, voltage dips, surges, insulation tests, and functional endurance tests to verify hardware robustness. -

6. Interface Compatibility:

Helps ensure consistent pin assignments, I/O module behavior, and connector types for field device integration.

In summary, IEC 61131-2 guarantees that PLC hardware is rugged, reliable, and capable of functioning in demanding industrial environments. Compliance with this part is critical for long-term system stability, safety, and regulatory acceptance.

What is IEC 61131-2? – PLC Hardware Requirements and Test Standards

IEC 61131-2 is the second part of the IEC 61131 standard and defines the hardware performance, environmental tolerances, and testing standards for Programmable Logic Controllers (PLCs) and their input/output modules. This standard ensures that PLC devices can operate safely and reliably in harsh industrial environments.

It specifies the minimum requirements and testing procedures for aspects like voltage levels, mechanical durability, immunity to electrical noise, and interface compatibility. IEC 61131-2 compliance helps manufacturers deliver robust PLC hardware that meets global industrial expectations.

-

1. Electrical Specifications:

Defines the required voltage ranges, signal levels, insulation resistance, and power tolerance that PLC I/O modules must comply with. -

2. Environmental Tolerance:

Sets limits for operating temperature, humidity, vibration, shock, and altitude — ensuring PLCs can withstand real-world industrial conditions. -

3. EMC (Electromagnetic Compatibility):

Requires PLC hardware to resist electromagnetic interference (EMI) and limits the emissions it produces to avoid disturbing nearby devices. -

4. Safety Isolation and Protection:

Specifies electrical isolation requirements between different PLC sections (e.g., CPU to I/O) and between PLCs and field equipment to prevent short circuits and hazards. -

5. Mechanical and Functional Testing:

Includes standardized performance tests such as surge protection, voltage dips, dielectric strength, and continuous operation endurance. -

6. Interface and Port Consistency:

Encourages hardware-level compatibility across I/O ports, connectors, and control signal interfaces between different vendors.

By complying with IEC 61131-2, manufacturers ensure their PLC hardware is rugged, durable, electrically safe, and globally accepted. This is essential for mission-critical industrial automation environments.

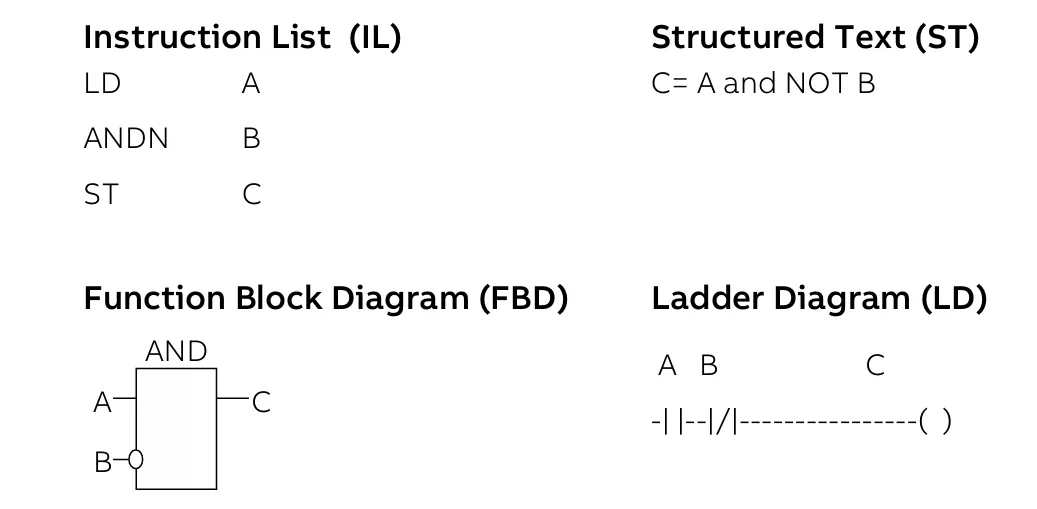

What is IEC 61131-3? – PLC Programming Languages Standard

IEC 61131-3 is the third and most significant part of the IEC 61131 standard. It defines the standard programming languages and software structure used in Programmable Logic Controllers (PLCs). This part is essential for achieving vendor-independent, modular, and reusable automation programs.

The standard introduces both graphical and textual programming languages, making it flexible for different types of developers. It also defines a common software model for how logic, tasks, variables, and program organization units (POUs) are managed across PLC platforms.

-

1. Supported Programming Languages:

IEC 61131-3 defines five PLC programming languages:- Ladder Diagram (LD): Graphical language based on relay logic, widely used in discrete manufacturing.

- Structured Text (ST): High-level, Pascal-like language for complex calculations and control flow.

- Function Block Diagram (FBD): Graphical blocks for logical and arithmetic operations, ideal for continuous processes.

- Sequential Function Chart (SFC): Used for process sequencing, step/transition-based logic.

- Instruction List (IL): Low-level assembly-style language (now deprecated in newer versions).

-

2. Program Organization Units (POUs):

Describes reusable code blocks like:- Programs: Main logic blocks that execute cyclically or event-based

- Function Blocks (FBs): Encapsulated logic with memory and reusable instances

- Functions: Stateless logic that returns a value

-

3. Data Types and Variables:

Supports strongly typed variables (BOOL, INT, REAL, STRING, etc.) and structures, arrays, and enumerations for reliable data handling. -

4. Execution Control:

Defines task scheduling, cyclic and event-driven execution, and multi-tasking features for real-time control. -

5. Portability and Reusability:

Programs developed using IEC 61131-3 languages are more portable across platforms, making projects easier to scale, maintain, and standardize.

Most modern PLC programming environments such as Siemens TIA Portal, Schneider EcoStruxure, Allen-Bradley Studio 5000, and Codesys are based on or compatible with IEC 61131-3.

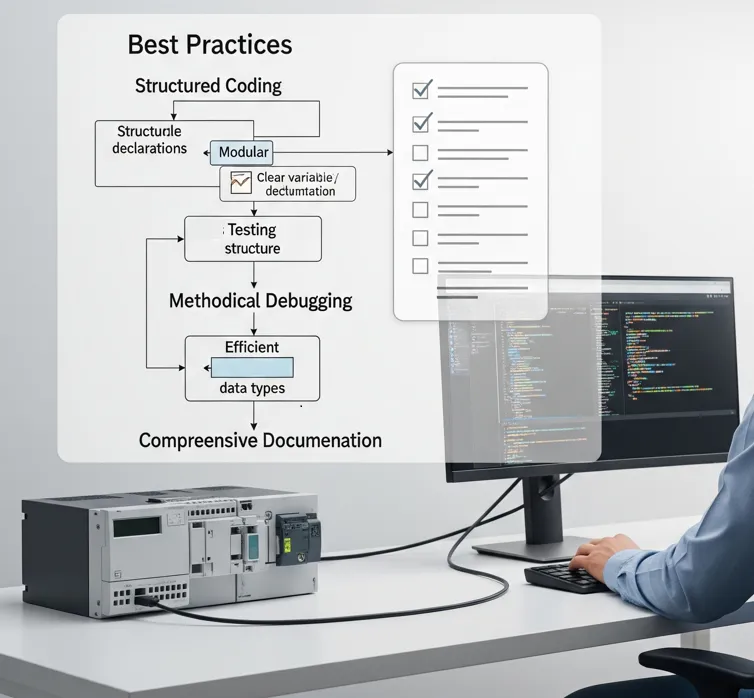

What is IEC 61131-4? – User Guidelines for PLC Programming

IEC 61131-4 provides guidelines and recommendations for applying the IEC 61131-3 programming languages effectively in real-world automation projects. While IEC 61131-3 defines the syntax and structure, IEC 61131-4 focuses on the best practices for programmers, integrators, and users working with industrial automation systems.

It aims to improve software portability, maintainability, modularity, and clarity. The standard is especially useful for teams collaborating across departments, companies, or geographical locations.

Key Features of IEC 61131-4:

- Standardized Design Practices: Encourages use of structured programming, naming conventions, modular function blocks, and consistent documentation.

- Project Lifecycle Recommendations: Covers development phases from planning, design, implementation, testing, commissioning, and maintenance.

- Team Collaboration: Offers advice for working in multi-developer environments, promoting reusable libraries and organized code structures.

- Error Handling Strategies: Suggests methods for incorporating diagnostics, fault management, and safe fallback routines.

- Human-Machine Interface (HMI) Considerations: Offers guidance on integration between control logic and user-facing interfaces.

By following IEC 61131-4, engineering teams can reduce training time, debugging effort, and operational risks—while increasing code clarity, transferability, and system uptime.

What is IEC 61131-5? – Communication for Programmable Controllers

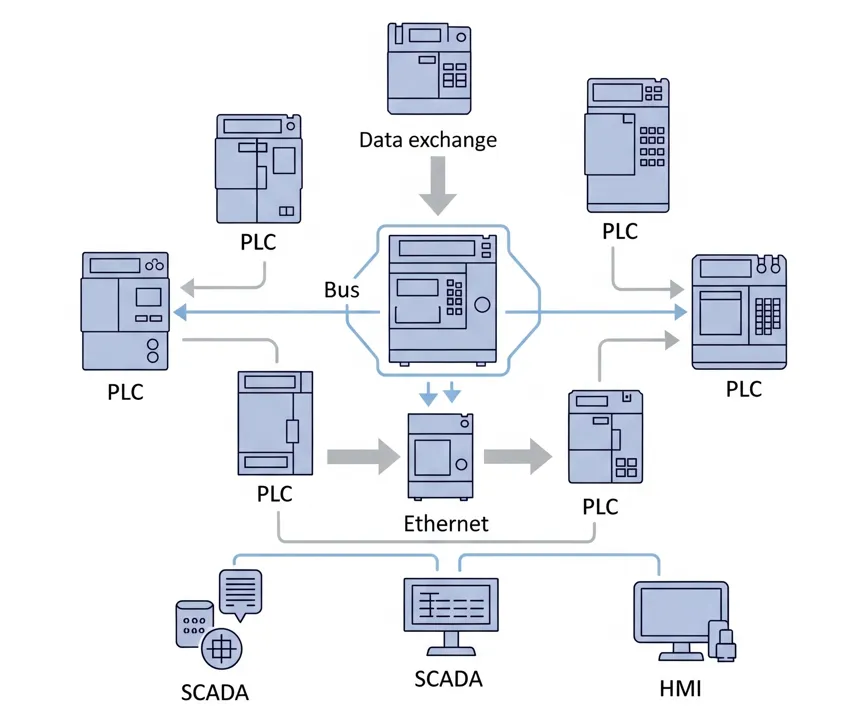

IEC 61131-5 defines the communication aspects of programmable controllers, focusing on data exchange between PLCs and other devices in industrial automation systems. It standardizes the communication services, interfaces, and models required for interoperability.

The main goal of this part is to ensure that PLCs from different manufacturers can communicate reliably across networks and systems, supporting distributed control architectures and factory-wide integration.

Key Elements of IEC 61131-5:

- Communication Models: Defines master-slave, client-server, and peer-to-peer interaction patterns for PLC communication.

- Interface Independence: Abstracts the communication interface from specific hardware protocols (like Modbus, Ethernet/IP, Profibus).

- Data Exchange Formats: Specifies how variables and messages should be structured and exchanged across systems.

- Synchronization and Timing: Addresses timing constraints, handshakes, and synchronization for real-time operations.

- Multi-vendor Support: Facilitates communication between PLCs and devices from different suppliers, enabling scalable systems.

This standard is especially valuable in IIoT, SCADA, and distributed automation environments where seamless and secure data flow between devices is essential.

What is IEC 61131-6? – Functional Safety for Programmable Controllers

IEC 61131-6 focuses on functional safety aspects of programmable logic controllers (PLCs) and control systems used in safety-related applications. It defines requirements for systems that must operate reliably and safely even in the presence of faults, errors, or abnormal conditions.

This part of the standard is used when designing Safety Instrumented Systems (SIS), emergency shutdown systems (ESD), fire and gas detection, or any system that could impact human safety or the environment if it fails.

Key Focus Areas of IEC 61131-6:

- Safety Integrity Levels (SIL): Specifies the performance and reliability required at different safety levels (SIL1 to SIL4).

- Redundancy and Fault Tolerance: Defines techniques such as dual-channel logic, watchdog timers, and hardware redundancy.

- Fail-Safe Operation: Systems must default to a safe state in case of failure (e.g., shutdown valves, stop motors).

- Validation and Testing: Emphasizes the importance of rigorous testing, diagnostics, and validation for safe system design.

- Compliance and Certification: Supports conformity with safety regulations such as IEC 61508 and ISO 13849.

IEC 61131-6 plays a crucial role in industries such as oil and gas, chemical, pharmaceuticals, manufacturing, and power where safety is paramount. It ensures that automation systems are not only functional but also fail-proof and secure.

Summary of IEC 61131 Standard Parts

The IEC 61131 standard is a comprehensive international guideline for programmable controllers used in industrial automation. It is divided into six parts, each focusing on a specific area of PLC design, programming, communication, and safety.

- IEC 61131-1 – General Information: Defines the basic terminology, system architecture, and operating principles of programmable controllers.

- IEC 61131-2 – Hardware Requirements: Specifies the electrical, mechanical, and environmental requirements for PLC hardware and I/O modules.

- IEC 61131-3 – Programming Languages: Introduces standard programming languages (LD, FBD, ST, IL, SFC) and a structured programming model for PLCs.

- IEC 61131-4 – User Guidelines: Provides practical application guidelines and good practices for programming, testing, and maintaining PLC systems.

- IEC 61131-5 – Communication: Standardizes communication models and interfaces for data exchange between PLCs and other systems.

- IEC 61131-6 – Functional Safety: Focuses on the safety requirements of PLCs used in critical applications like emergency shutdown or safety instrumented systems.

Together, these parts create a unified framework for developing, maintaining, and scaling reliable automation systems across industries.