PLC (Programmable Logic Controller) – Basics, Types, and Applications

Published on July 16, 2024 | Category: introductionShare this Page:

PLC (Programmable Logic Controller) is a digital control system that replaces complex hardwired relay logic with a flexible, programmable solution. It stores instructions to control industrial machines, systems, and processes based on input and output conditions. PLCs are widely used in automation to monitor sensors, execute control logic, and operate devices like motors, pumps, valves, and alarms. They are essential in industries such as manufacturing, water treatment, HVAC, packaging, and process control. This page provides a simple overview of PLC basics, working principles, types, and real-world applications to help students, technicians, and engineers understand how PLCs automate industrial operations.

The evolution of PLCs has passed through multiple stages, improving with each technological advancement. One of the major milestones was the integration of digital components that enabled precise timing, synchronization, and counting functions. Later, the adoption of microprocessors significantly enhanced processing power, flexibility, and programmability, making modern PLCs compact, reliable, and capable of handling complex automation tasks.

PLCs are programmed using dedicated software and graphical languages like Ladder Logic, Function Block Diagram (FBD), and Structured Text. The control program is designed according to the specific needs of the process or machine. Once programmed, the PLC continuously scans input conditions, executes the logic, and updates outputs in real time. This ability to customize logic and respond instantly to changing conditions makes PLCs a core component of modern industrial automation systems.

What is PLC?

A PLC (Programmable Logic Controller) is an industrial digital controller used to automate machinery, processes, and production lines. It continuously monitors input signals from field devices such as sensors, switches, and push buttons, executes a control program written in languages like Ladder Logic or Structured Text, and updates outputs to devices such as motors, valves, and alarms. The PLC makes decisions based on real-time input conditions and logic instructions, enabling precise, repeatable, and reliable automation. For example, a PLC can be programmed to start a motor when a start button is pressed and stop it automatically when a limit switch is triggered. By replacing traditional hardwired relay systems, PLCs provide flexible and scalable control solutions in industries such as manufacturing, water treatment, packaging, and energy.

What is a PLC Meaning?

PLC stands for Programmable Logic Controller. It is a digital industrial control device designed to monitor inputs, execute a programmed logic sequence, and control outputs based on that logic. PLCs are used to automate machines, equipment, and processes in industries such as manufacturing, energy, water treatment, and packaging. Unlike traditional control systems that rely on fixed wiring, a PLC uses a software-based program—usually written in Ladder Logic or other IEC 61131-3 languages—to make decisions and perform specific tasks automatically.

What is the Basic Concept of PLC?

The basic concept of a PLC (Programmable Logic Controller) is to provide an automated way to control industrial machines and processes based on logic defined by the user. A PLC continuously reads input signals from sensors or switches, processes those signals according to a program stored in its memory, and then activates output devices such as motors, lights, or valves. This cycle repeats in real time, allowing fast and reliable control of equipment. PLCs are designed to replace hardwired control systems with a programmable and flexible solution that is easy to update and maintain.

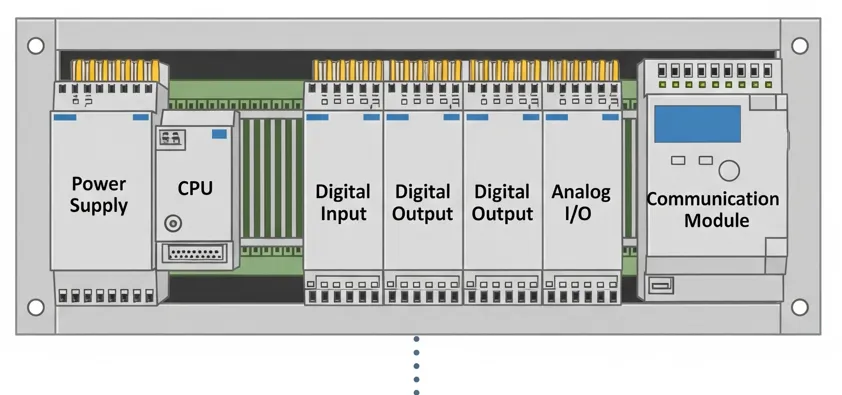

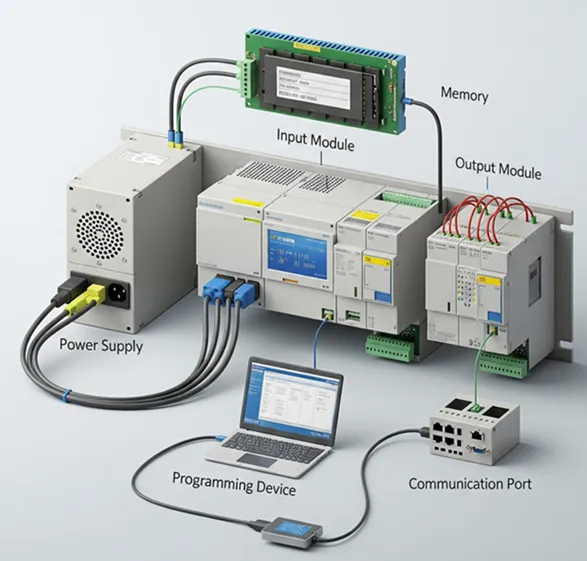

Basic Components of PLC

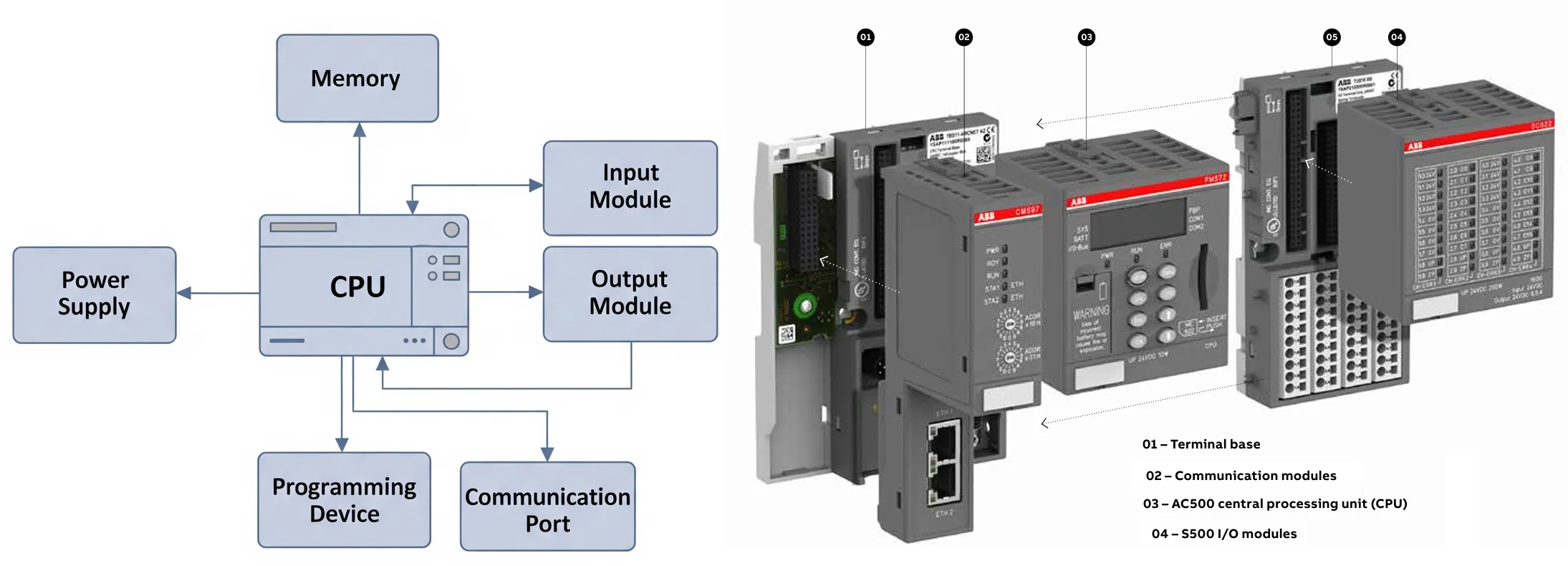

A PLC (Programmable Logic Controller) consists of several key components that work together to control industrial systems. The basic components include:

- Power Supply: Provides the required voltage to the PLC system.

- CPU (Central Processing Unit): The brain of the PLC that processes the control program and manages all operations.

- Input Module: Receives signals from field devices like sensors and switches.

- Output Module: Sends control signals to devices such as motors, lights, and valves.

- Programming Device: A computer or HMI used to write, load, and monitor the PLC program.

- Communication Port: Allows the PLC to connect with other systems like SCADA, HMI, or other PLCs.

- Memory: Stores the user program, system configuration, and real-time data.

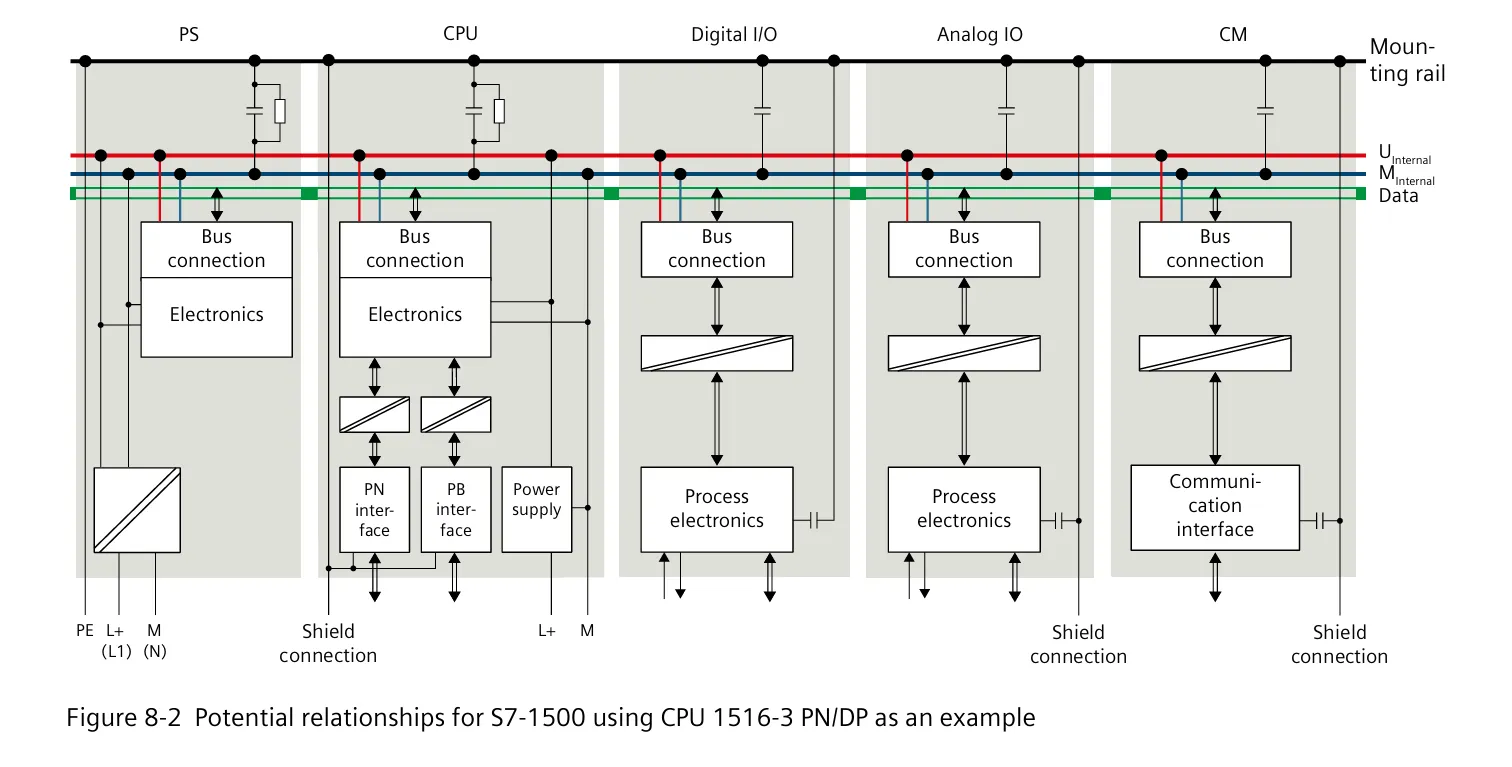

PLC Power Supply Unit

The Power Supply Unit in a PLC system is responsible for converting incoming AC or DC voltage into a stable voltage level required by the internal components of the PLC. Typically, it provides 5V, 12V, or 24V DC power to the CPU, I/O modules, and communication interfaces. A reliable power supply ensures stable operation of the PLC even in harsh industrial environments. Some PLCs have built-in power supplies, while larger systems may use separate, modular power supply units.

What is PLC CPU Unit and How It Works?

PLC CPU Unit

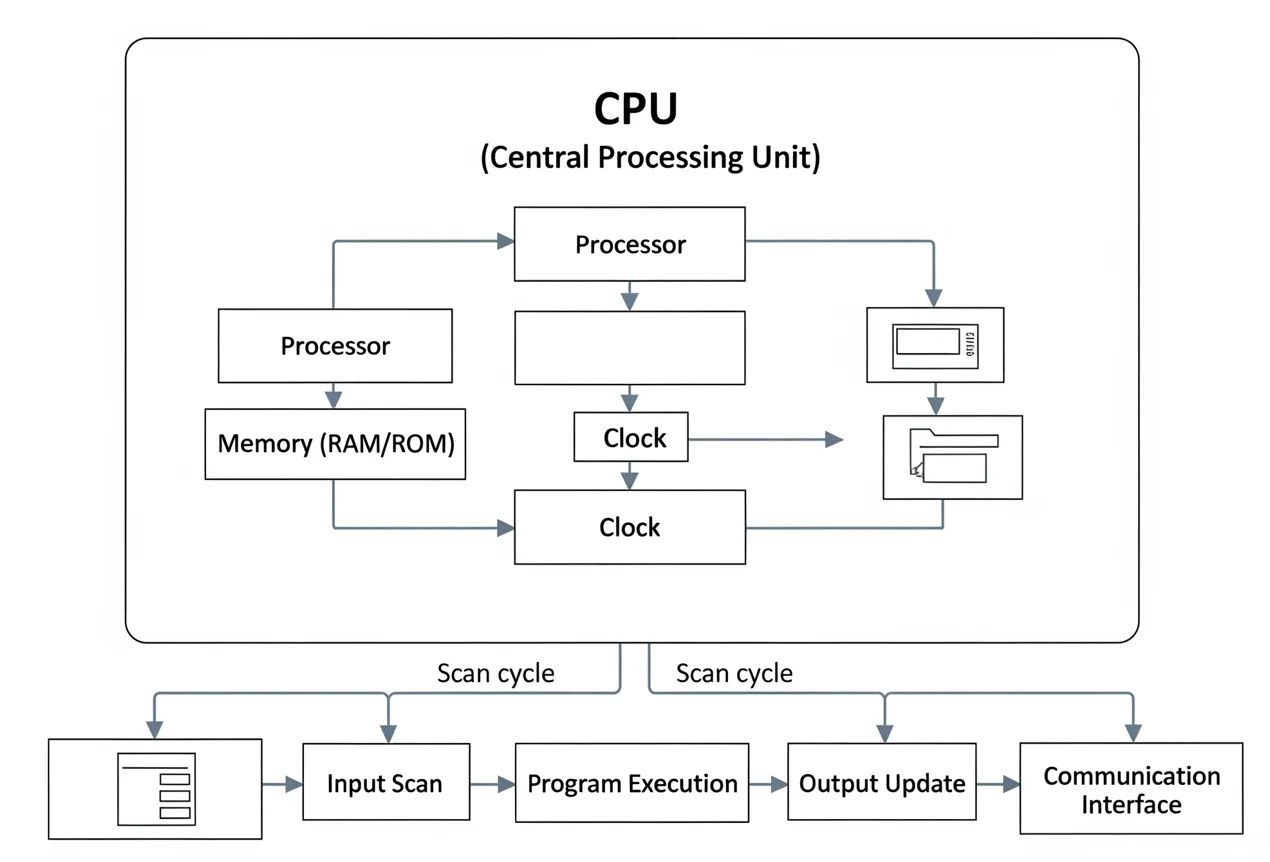

The CPU (Central Processing Unit) is the most critical part of a PLC. It acts as the brain of the system, executing the control program and coordinating all activities within the PLC. The CPU continuously monitors input signals, processes them according to the user-defined logic, and updates the output signals accordingly. This process is known as the PLC scan cycle.

The scan cycle consists of three main steps: 1) Input Scan – reads the current status of all input devices, 2) Program Execution – executes the logic instructions stored in memory, and 3) Output Update – sends the updated signals to output devices like motors or relays. This cycle is repeated continuously in milliseconds, ensuring real-time control.

The CPU also contains different types of memory:

- RAM (Random Access Memory): Stores temporary data, I/O status, and variable values during operation.

- ROM (Read-Only Memory): Stores the system firmware and fixed data.

- EPROM/EEPROM: Used to store user programs permanently, even when power is turned off.

In addition to processing logic, the CPU manages communication interfaces (such as RS-232, Ethernet, or fieldbus), diagnostic functions, and internal clock operations. A reliable CPU ensures that the PLC can respond quickly, accurately, and safely to changing conditions in the process it controls.

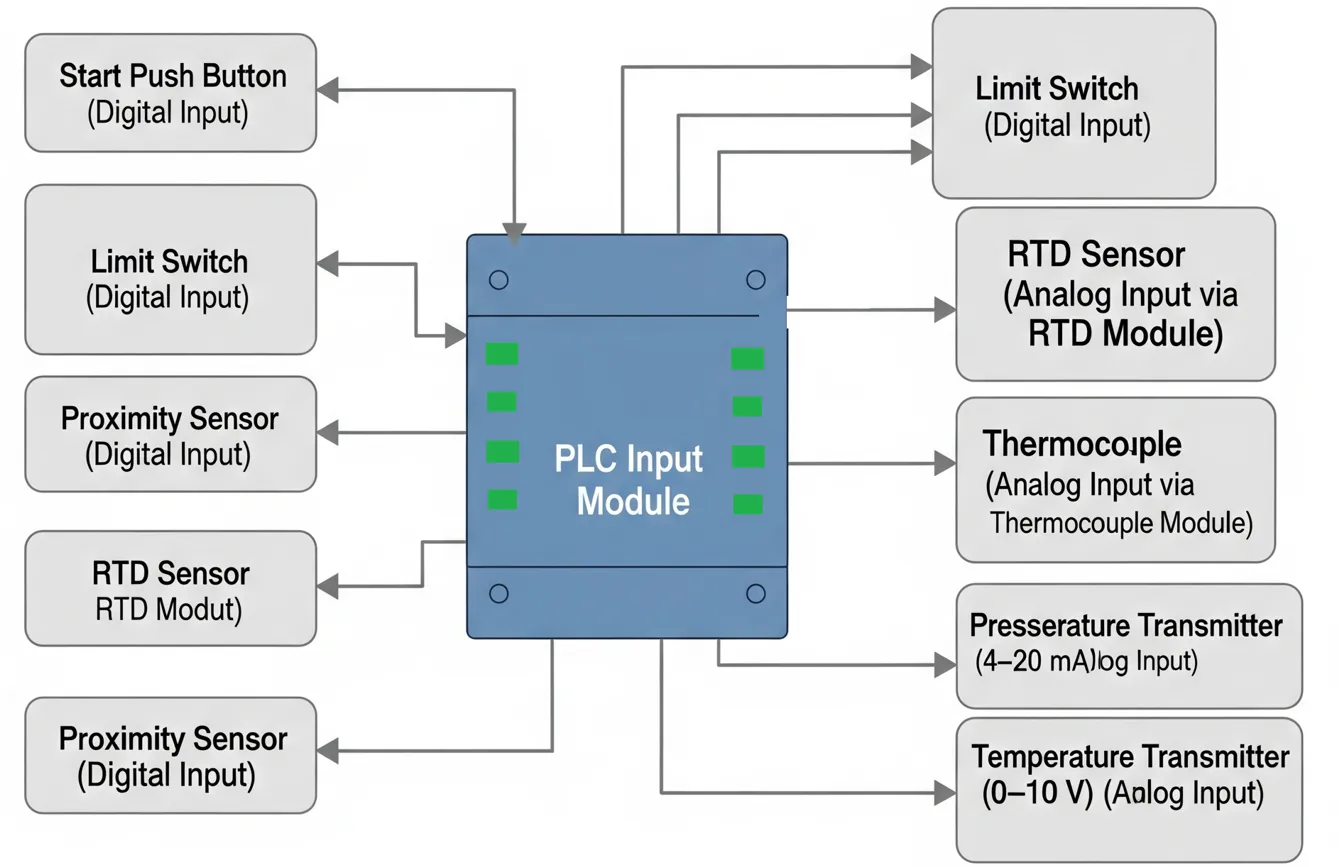

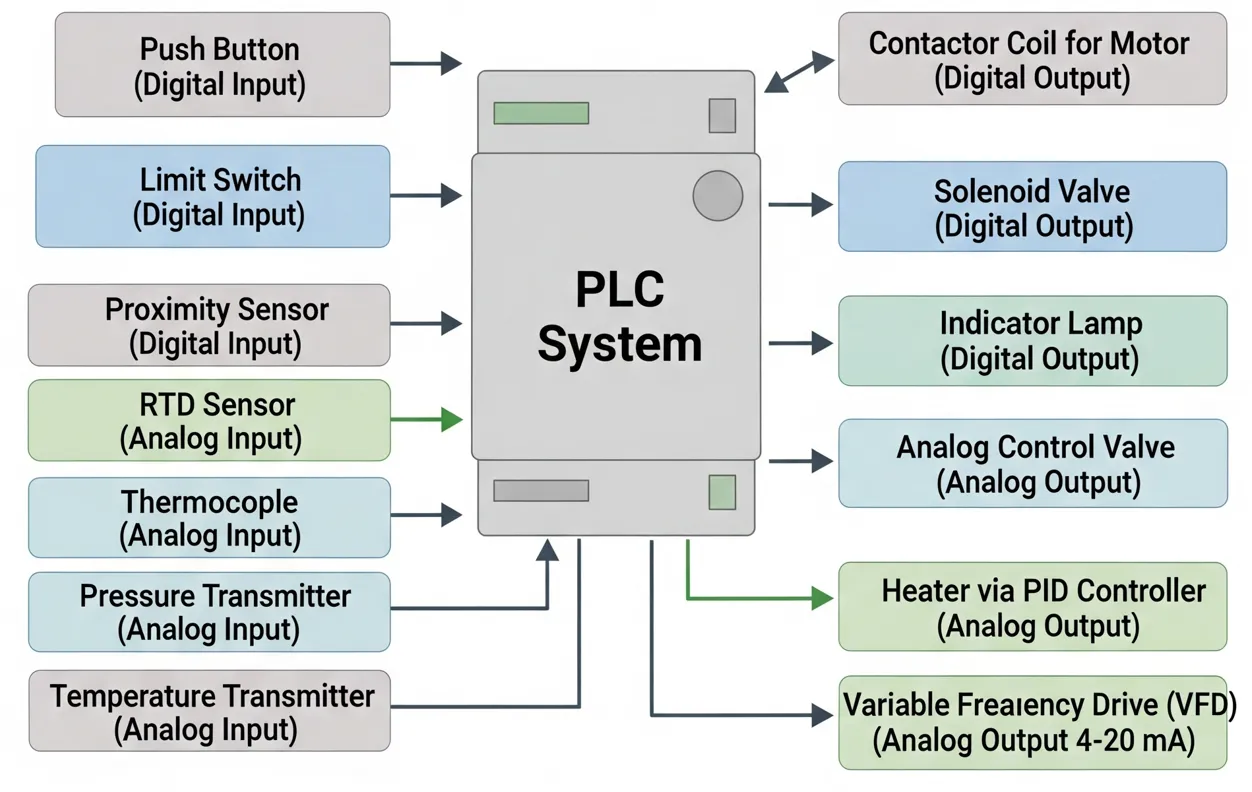

PLC Input Module – Definition and Working

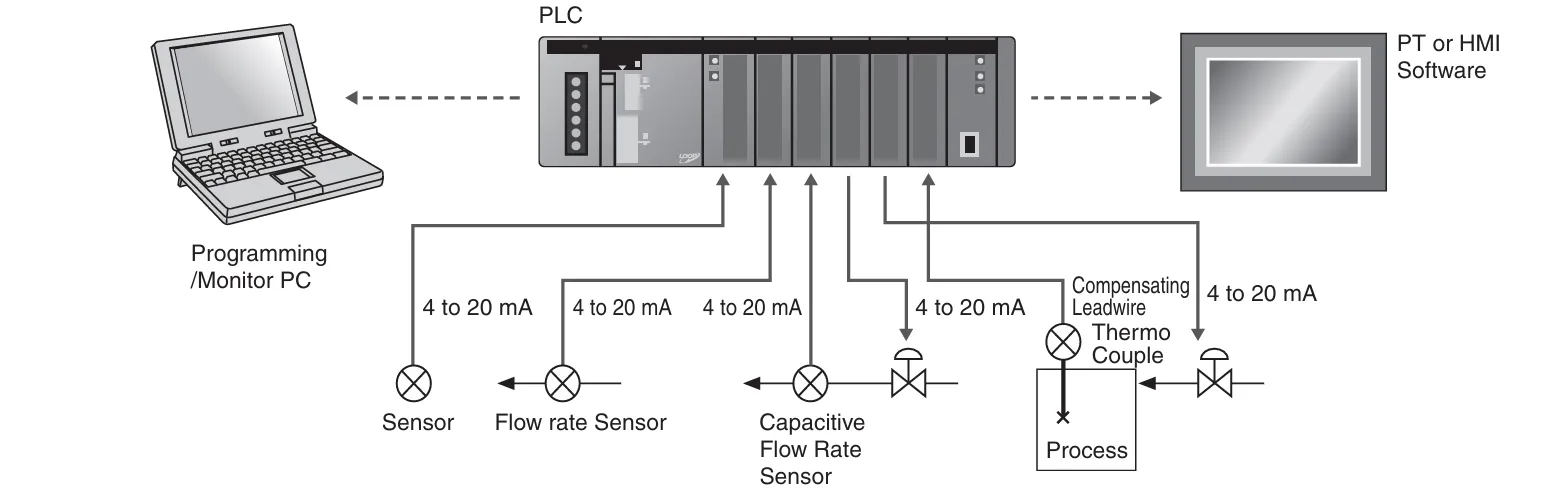

A PLC Input Module is a hardware component used to receive signals from field devices such as sensors, switches, and push buttons. These devices detect conditions in the real world—like temperature, pressure, or level—and send electrical signals to the PLC. The input module converts these signals into digital or analog values that the CPU can read and process.

There are two main types of PLC input modules:

- Digital Input Module: Accepts ON/OFF signals (e.g., from push buttons, limit switches, proximity sensors).

- Analog Input Module: Accepts variable signals (e.g., 0–10V, 4–20mA) from sensors such as:

- Temperature sensors (RTDs, Thermocouples)

- Pressure or level transmitters

- Flow meters

- Process signals used in PID control loops

Each input is assigned a specific address in the PLC program. During the scan cycle, the CPU reads these inputs, processes the logic, and updates outputs accordingly. The accuracy and reliability of input modules are essential for real-time industrial control.

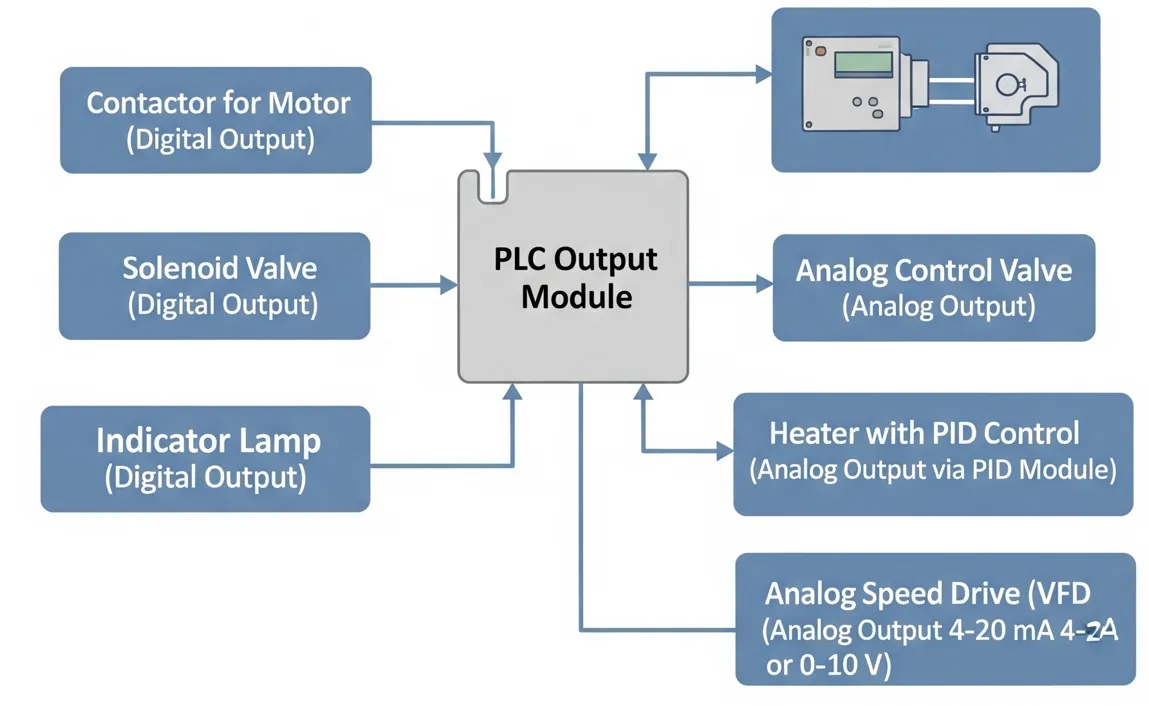

PLC Output Module – Types and Function

A PLC Output Module is responsible for sending control signals from the CPU to external field devices that perform actions. After processing the input conditions based on the logic program, the CPU uses the output module to activate devices like motors, relays, solenoids, control valves, buzzers, and indicator lamps. It acts as the interface between the PLC and the real-world output devices.

There are two major types of output modules:

- Digital Output Module: Sends discrete ON/OFF signals to devices such as:

- Contactors and motor starters

- Solenoid valves

- Indicator lamps and buzzers

- Relay outputs for alarms

- Analog Output Module: Sends continuous signals (e.g., 4–20mA, 0–10V) to control:

- Variable speed drives (VFDs)

- Proportional control valves

- Analog actuators

- PID-controlled process elements

Each output device is assigned a unique address in the PLC program. The CPU continuously scans and updates output states based on the current input conditions and logic instructions, allowing for real-time process control and automation.

Types of PLC Input and Output Modules

PLC Input Modules

- Digital Input Module: Receives ON/OFF signals from field devices such as push buttons, limit switches, proximity sensors, and emergency stops.

- Analog Input Module: Accepts continuous signals (e.g., 4–20 mA, 0–10 V) from sensors measuring parameters like pressure, level, or flow.

- RTD Input Module: Specifically designed to receive temperature signals from Resistance Temperature Detectors (RTDs).

- Thermocouple Input Module: Processes millivolt-level signals from thermocouples (types J, K, T, etc.) for temperature measurement.

- High-Speed Input Module: Used for applications requiring fast signal capture like encoders, counters, and pulse signals.

PLC Output Modules

- Digital Output Module: Sends ON/OFF control signals to field devices such as contactors, relays, lamps, and solenoid valves.

- Analog Output Module: Sends continuous control signals (e.g., 4–20 mA, 0–10 V) to actuators like control valves, drives, or analog indicators.

- PWM Output Module: Provides pulse-width modulated signals used for motor speed control or LED dimming.

- PID Control Module: Dedicated module to execute closed-loop control logic for temperature, pressure, or flow based on feedback from input modules.

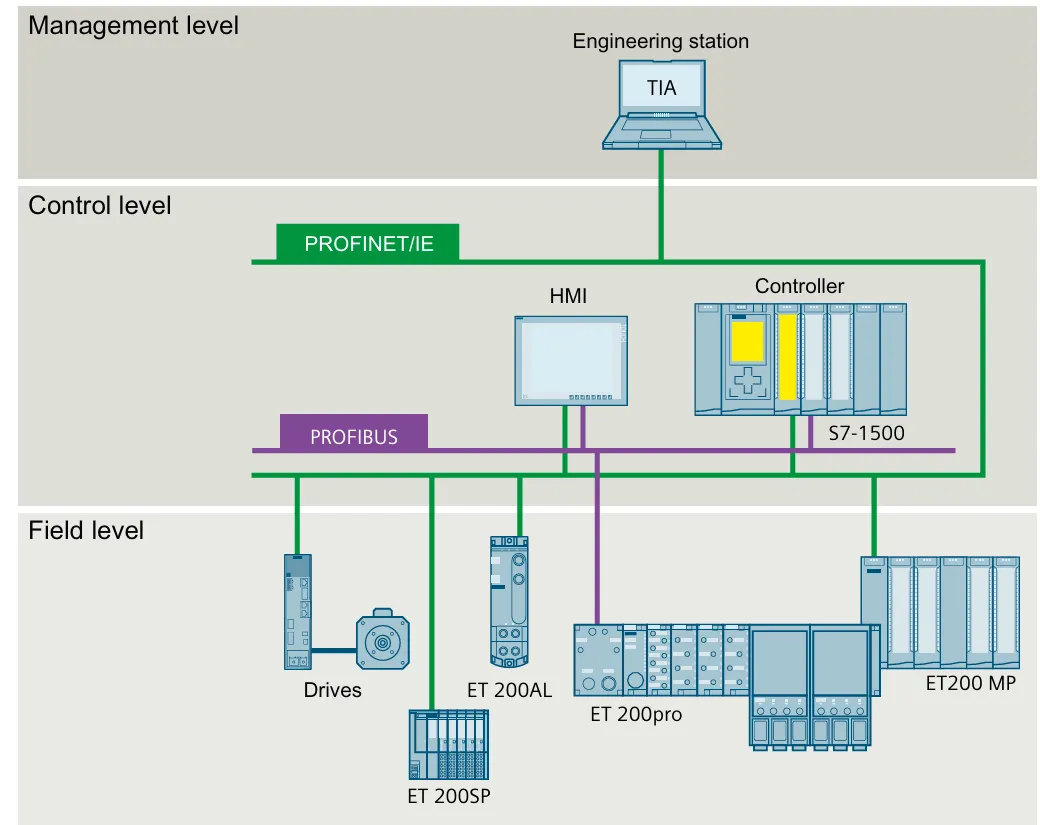

PLC Communication Module – Purpose and Types

A PLC Communication Module enables data exchange between the PLC and external systems such as HMIs, SCADA, other PLCs, and remote I/O devices. These modules are essential for monitoring, data logging, supervisory control, and integration with plant-level or enterprise-level networks.

Communication modules support various industrial protocols to ensure reliable and fast data transfer. Common types include:

- Ethernet/IP Module: Used for high-speed communication with HMIs, SCADA, and other controllers.

- Modbus RTU/Modbus TCP Module: Widely used open protocol for connecting PLCs with instruments, drives, and third-party devices.

- Profibus Module: Common in process industries for field-level device communication.

- DeviceNet/ControlNet: Used for deterministic communication in real-time control systems.

- RS-232/RS-485 Serial Modules: For legacy devices and point-to-point communication.

With communication modules, PLCs can exchange input/output data, share memory tags, send alarms, and synchronize operations across multiple systems. This improves automation efficiency and ensures centralized control and visibility of the entire process.

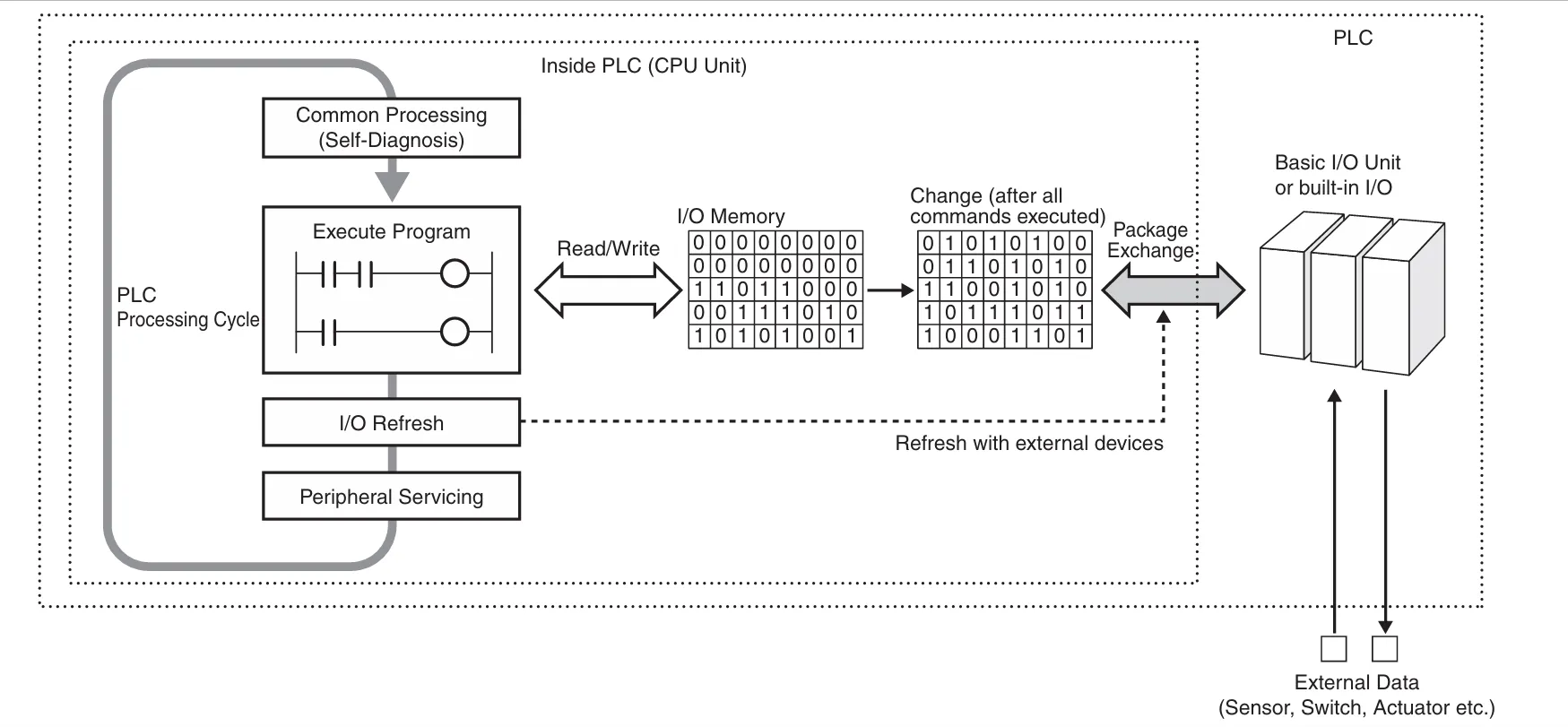

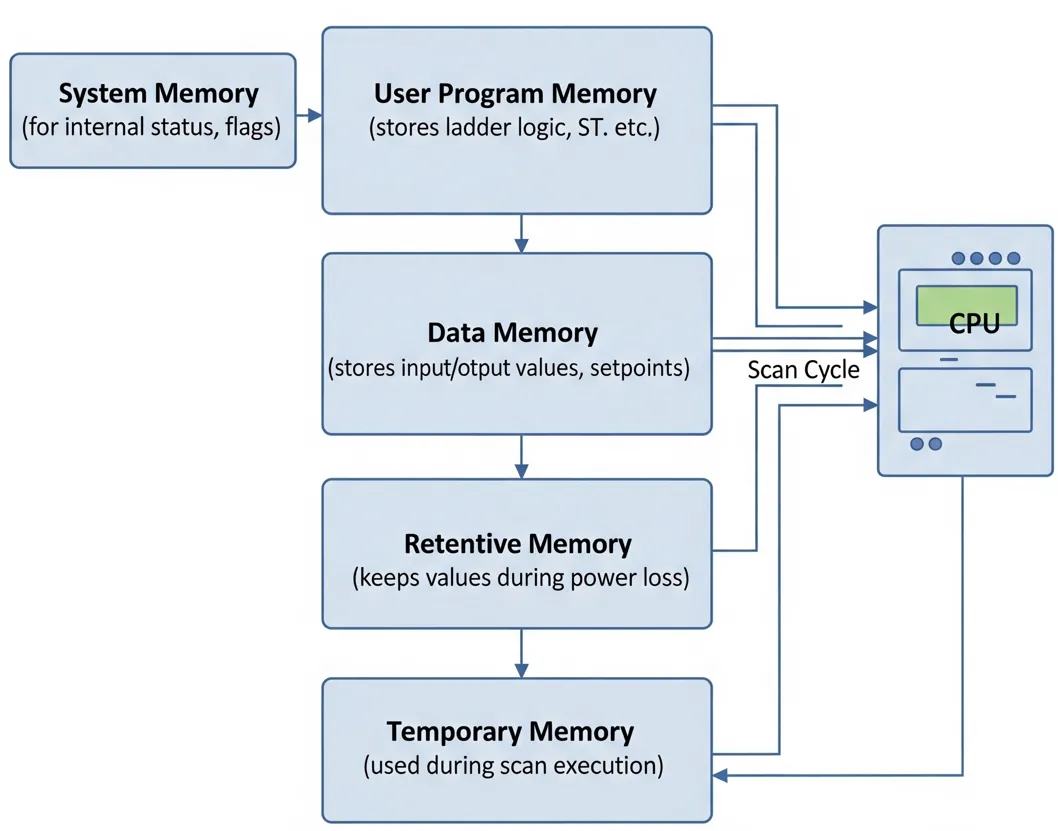

PLC Memory Unit – RAM, ROM, and Data Handling

The PLC Memory Unit stores all essential information required for program execution, system operation, and process control. It holds the user-defined control program, real-time input/output status, setpoints, and internal variables such as timers and counters. Without memory, the PLC cannot retain or execute control logic.

The memory in a PLC is divided into several key types:

- RAM (Random Access Memory): Temporary memory used during program execution. It stores real-time data, intermediate results, and I/O status, which gets cleared during power loss.

- ROM (Read-Only Memory): Permanent memory that stores the operating system and firmware, essential for PLC startup and internal system functions.

- EEPROM/Flash Memory: Used for non-volatile storage of the user program and configuration data. It retains data even after power loss.

During the PLC scan cycle, the memory unit plays a vital role by storing:

- Input status from sensors and switches

- Control logic and instruction blocks

- Output status for actuators

- System flags, internal bits, counters, and timers

Understanding the PLC Scan Cycle – Input to Output

The PLC Scan Cycle is the continuous process that a Programmable Logic Controller (PLC) follows to monitor and control industrial systems. This cycle ensures that the PLC reads real-world signals, processes the program logic, and sends updated signals to output devices in real time. The cycle repeats hundreds or thousands of times per second depending on the complexity of the program and hardware speed.

The standard scan cycle consists of the following steps:

- 1. Input Scan: The PLC reads current statuses from all input devices (sensors, switches, etc.) and stores them in memory.

- 2. Program Execution: The PLC executes the user-defined program logic (ladder, ST, etc.) using the stored input values.

- 3. Output Scan: Based on the program results, the PLC updates the output devices such as motors, valves, and alarms.

- 4. Housekeeping: The PLC performs internal diagnostics, communication tasks, and updates system flags or counters.

This real-time, cyclic operation allows the PLC to react to input changes and update output responses instantly. A typical scan time ranges from a few milliseconds to tens of milliseconds, depending on program size and hardware.

Types of PLC – Classification Based on Size and Use

PLCs (Programmable Logic Controllers) are categorized into different types based on their size, processing power, number of I/O points, and application scope. Choosing the right type of PLC is crucial for the efficiency, flexibility, and scalability of an industrial automation system.

The main types of PLCs include:

- 1. Compact or Fixed PLC: These PLCs come with a fixed number of input/output points and built-in power supply and CPU. They are ideal for small-scale applications like packaging machines, conveyors, and small equipment.

- 2. Modular PLC: Modular PLCs allow users to add or replace I/O modules, power supply units, and communication modules. Suitable for medium to large applications where scalability and flexibility are required.

- 3. Rack-Mounted PLC: These are advanced systems where modules (CPU, I/O, communication) are mounted on standard racks. Common in large-scale industrial plants like refineries, manufacturing units, and utility control.

- 4. Soft PLC: A software-based PLC that runs on a standard PC using real-time operating systems. Mostly used in training, simulation, and SCADA-integrated environments.

Each type of PLC offers unique benefits depending on the complexity of the task, the environment, and communication needs. For example, compact PLCs suit standalone operations, while modular or rack-based PLCs are used in distributed control environments.

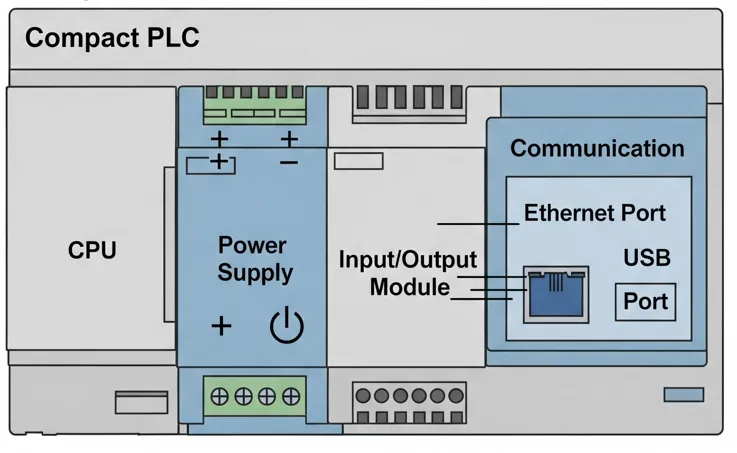

What is a Compact PLC?

A Compact PLC, also known as a Fixed PLC, is a type of Programmable Logic Controller with a pre-configured structure. It comes with a built-in CPU, fixed number of input/output (I/O) points, and often includes a power supply—all in a single housing unit. Unlike modular PLCs, compact PLCs do not allow expansion of I/O modules, making them ideal for small-scale and standalone automation systems.

Compact PLCs are easy to install and program, making them popular in applications like conveyor control, packaging machines, bottle filling units, and simple batch processes. These PLCs are cost-effective, space-saving, and efficient for handling basic automation tasks with limited I/O requirements.

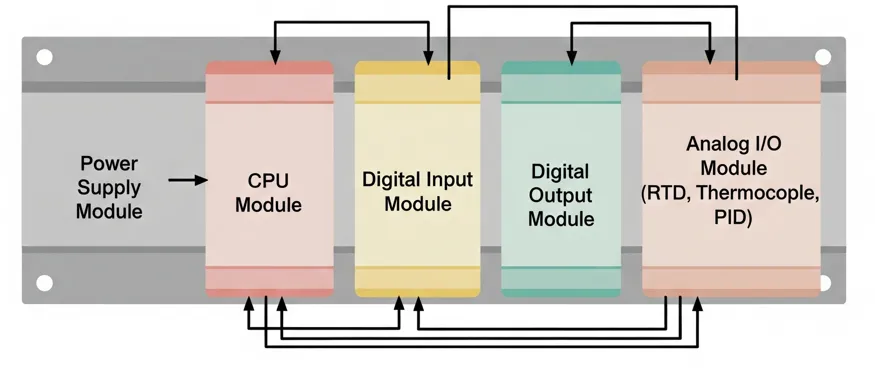

What is a Modular PLC?

A Modular PLC is a type of Programmable Logic Controller made up of separate, plug-in modules for the CPU, power supply, and input/output (I/O) channels. These modules are installed on a base or backplane, allowing users to customize and expand the PLC according to the needs of the automation system.

The modular structure allows engineers to easily add or replace I/O modules, communication cards, or specialized function blocks such as analog, temperature, RTD, PID, or high-speed counters. This flexibility makes modular PLCs suitable for medium to large-scale industrial applications such as process control systems, large packaging lines, energy management, and plant automation.

Modular PLCs are scalable and serviceable, supporting remote I/O communication and complex control tasks. They are preferred in systems where process complexity may grow over time or require integration with SCADA, HMI, or DCS systems.

What is a Rack-Mounted PLC?

A Rack-Mounted PLC is an advanced type of Modular PLC where all modules such as CPU, power supply, and I/O units are installed on a rack or chassis system. This rack acts as a backplane that connects all modules electrically and mechanically, allowing data exchange and power distribution across modules.

Rack-mounted PLCs are designed for large-scale, high-performance industrial applications where system expandability, redundancy, and distributed control are required. Multiple racks can be connected in a single system using remote I/O and communication modules, supporting thousands of I/O points and complex control logic.

These PLCs are commonly used in heavy industries like power plants, oil & gas, automotive assembly lines, water treatment facilities, and complex manufacturing processes. Their modular and distributed architecture ensures easy maintenance, scalability, and system reliability.