Share on Facebook

Share On Twitter

Share on LinkedIn

Share on Whatsapp

FPWIN Pro is the Panasonic programming software for panasonic plc. fpwin pro easy to programs of plc. fpwin supports simulation process for plc so you can easily simulate your program without having plc. it is easy to learn and practice.

in this article we will learn how to program using ladder digram. so follow these steps for a simple program in simulation mode.

open Fpwin software, and create a new project click on "project" >"new" > "new project wizard" or simply ctrl+N

enter folowing project details in project wizard

Click on the required contact

Comile and check your program

Check the program using

Download the program to the PLC

before doing this check your communication setting. Connect the PLC to the computer using the programming cable.If communication problems occur, check the communication parameters.for checking communication parameter go to submenus of the online menu, you set the parameters which have to do with working in the online mode.

Switch to online mode by clicking

Change to RUN mode by clicking

start your first program with panasonic plc FPWIN Pro

FPWIN Pro is the Panasonic programming software for panasonic plc. fpwin pro easy to programs of plc. fpwin supports simulation process for plc so you can easily simulate your program without having plc. it is easy to learn and practice.

in this article we will learn how to program using ladder digram. so follow these steps for a simple program in simulation mode.

- suported plc: FP-X, FP-e,FP-X0(FP-X0 L14/30, FP-X0 L40/60), FP-X,FP-e, FPS, FP0, FP0R, FP2, FP3, FP5, FP10/10S, FP10SH, FP2SH, FP7 etc.

- it support five IEC 61131-3 plc programming language you can choose any of them,Instruction List(IL), Structured Text, Ladder Diagram, Function Block Diagram, Sequential Function Chart.

open Fpwin software, and create a new project click on "project" >"new" > "new project wizard" or simply ctrl+N

enter folowing project details in project wizard

- PLC Type :Select or Change PLC Type. Select "Change PLC Type" to open a dialog in which all PLC types are listed.

- Name specify the name for the project's first program. This program is assigned to the "Programs" task when the project is created. Then it is processed each cycle by the PLC.

- language: select your following plc programmming language type

- To create a project containing the newly defined program, select "Create project.

- To create a project without any program, e.g. if you need to import objects (*.asc, *.st, *.type), select [Create empty project].

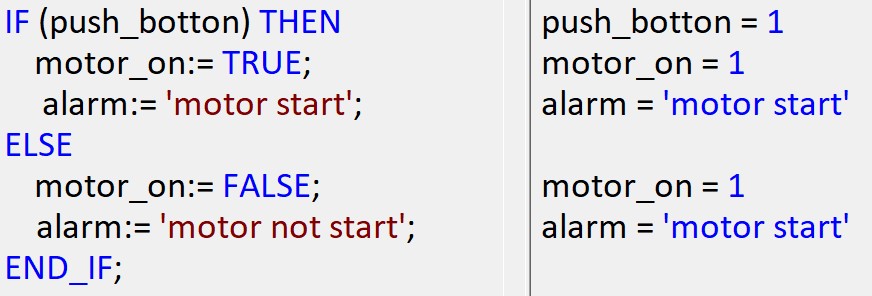

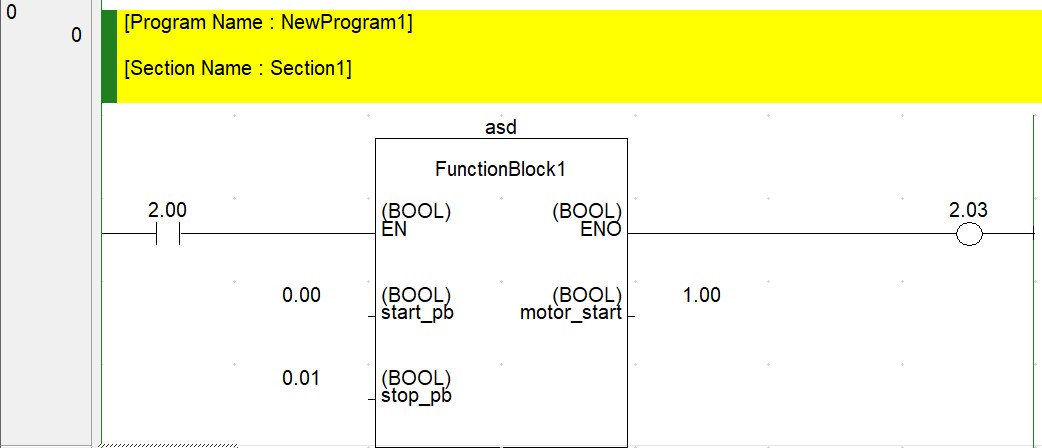

make a simple program by adding a contact and coil

Click on the required contact  and coil

and coil in the toolbar or choose the item from the context menu Place them into network 1 of the programming window,Click on the question mark of the contact and the coil

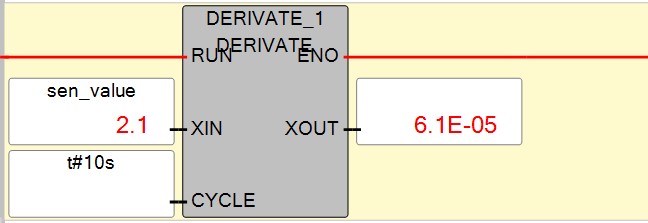

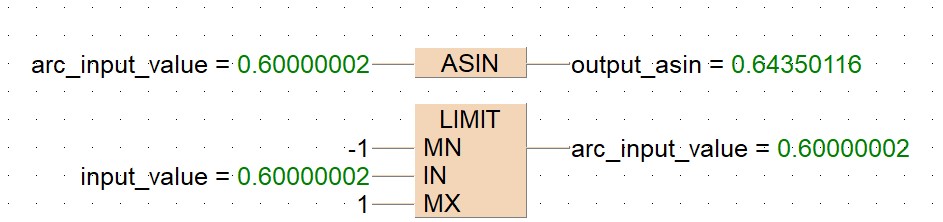

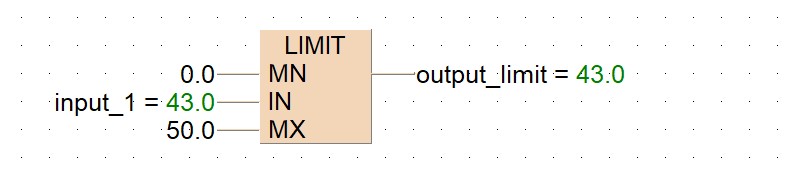

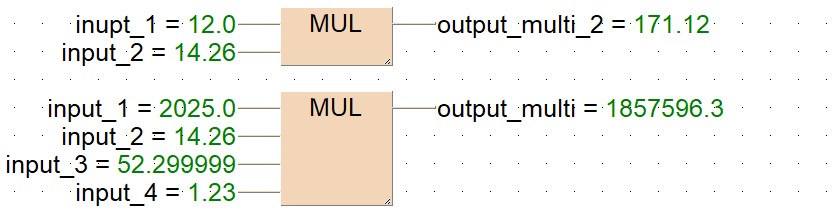

Enter an identifier for the variable, e.g. input and output. if you want to inser block like timer, comparing block, arthmitic block select these from instrunction list of the window and them in programming window assign variable and data types as required. for more details of all type of instrunction of panasonic we will discuss next articles.

in the toolbar or choose the item from the context menu Place them into network 1 of the programming window,Click on the question mark of the contact and the coil

Enter an identifier for the variable, e.g. input and output. if you want to inser block like timer, comparing block, arthmitic block select these from instrunction list of the window and them in programming window assign variable and data types as required. for more details of all type of instrunction of panasonic we will discuss next articles.

Comile and check your program

Check the program using  or from the context menu. A message will inform you if your program is OK or not. If needed, modify errors, e.g. double lines. If more than one error occurs, fix the first one first. The others could be sequence errors.

or from the context menu. A message will inform you if your program is OK or not. If needed, modify errors, e.g. double lines. If more than one error occurs, fix the first one first. The others could be sequence errors.

You can toggle between the remote run and remote programming via the toolbar.

You can toggle between the remote run and remote programming via the toolbar.

Download the program to the PLC by clicking

Download the program to the PLC by clicking Confirm by compiling all.

Confirm by compiling all. . Start monitoring by clicking

. Start monitoring by clicking  and check your program. we will discuss about other instrunction next article.

and check your program. we will discuss about other instrunction next article.