How to Learn PLC Programming – Beginner to Advanced Guide

Published on Aug 18, 2024 | Category: ProgrammingShare this Page:

A Programmable Logic Controller (PLC) is a rugged industrial computer used to monitor inputs, make logic decisions, and control outputs for processes such as cement manufacturing, power plants, packaging lines, and building automation. If you’re a student or an engineer wondering how to learn PLC programming, this guide explains what PLCs are, where these skills are used, and the practical steps to begin your learning journey.

PLC programming skills are in demand across manufacturing, automotive, food and beverage, water treatment, oil and gas, HVAC/BMS, and material handling. While PLC hardware and licensed software can be expensive, most major vendors provide student editions, learning editions, or fully featured trial versions (often 30 days). Even after a trial ends, limited-feature modes are usually enough to practice ladder logic, timers, counters, data handling, and basic diagnostics without purchasing hardware.

In this article, you’ll learn a clear, step-by-step method to build PLC skills: understanding core concepts, setting up vendor trial software, practicing with built-in simulators, and working through real-world mini projects. The goal is to help you grow as an automation engineer—cost-effectively—by focusing on hands-on learning paths, essential tools, and smart ways to practice without owning expensive devices.

What is PLC?

A Programmable Logic Controller (PLC) is a specialized industrial computer designed to control machines and processes. It receives signals from input devices such as sensors, processes the information using a programmed logic, and then sends commands to output devices like motors, valves, or alarms. PLCs are built to work in harsh industrial environments and are widely used in industries such as cement, steel, power plants, automotive, and packaging.

What is PLC Programming?

PLC programming is the process of creating a set of instructions that a PLC follows to perform control tasks. The most common programming language is Ladder Logic, which uses symbols similar to electrical relay diagrams. Other languages include Function Block Diagram (FBD), Structured Text (ST), and Sequential Function Chart (SFC). By learning PLC programming, engineers can design, troubleshoot, and optimize industrial automation systems.

Step 1 – Learn Basic Electrical Engineering

Before starting with PLC programming, it is important to have a foundation in basic electrical engineering. Understanding how electrical components work will make it easier to design, program, and troubleshoot automation systems. PLCs deal directly with electrical signals from sensors and actuators, so this knowledge is essential.

Key topics to focus on include:

- Power Supply – Learn how AC and DC power is generated and used in control systems.

- AC & DC Circuits – Understand the difference between alternating current and direct current.

- Resistors – Components that limit or control the flow of current.

- Capacitors – Store and release energy, used for filtering and power conditioning.

- Motors – Basics of AC and DC motors, since PLCs often control motor operations.

- Transformers – Devices that step up or step down voltage in power systems.

- CT (Current Transformer) – Measures current for protection and metering.

- PT (Potential Transformer) – Steps down high voltage to safe levels for measurement.

- Earthing & Protection (ERTC) – Learn grounding, fuses, MCBs, and protection systems for safety.

Once you understand these fundamentals, you’ll be better prepared to work with PLC hardware, wiring, and troubleshooting in real-world industrial applications.

imgStep 2 – Learn Basic Instrumentation

After building a foundation in electrical engineering, the next step is to understand the basics of instrumentation. PLCs interact with field devices such as sensors, switches, and transmitters. Knowing how these instruments work will help you program PLCs more effectively and troubleshoot problems in automation systems.

Important instrumentation topics to learn include:

- Switches – Simple devices to start or stop electrical signals, such as push buttons and limit switches.

- Relays – Electromechanical devices used to control high-power circuits with low-power signals.

- Transmitters – Convert physical parameters like pressure, flow, or temperature into standard signals (4–20 mA, 0–10 V).

- ADC (Analog to Digital Converter) – Converts analog signals from sensors into digital data for PLC input.

- RTD (Resistance Temperature Detector) – A temperature sensor that changes resistance with temperature.

- Thermocouples & Temperature Measurement – Devices used for accurate temperature monitoring in industries.

- Proximity & Level Sensors – Detect objects, positions, or material levels without physical contact.

- Flow & Pressure Instruments – Measure process variables that PLCs control in automation systems.

A clear understanding of these instruments will give you the confidence to connect, configure, and program them with a PLC in real projects.

Step 3 – Select a PLC Brand and Software

Once you are comfortable with electrical and instrumentation basics, the next step is to select a PLC brand. There are many manufacturers in the market such as Siemens, Allen-Bradley (AB), Delta, Schneider, Honeywell, ABB, and Panasonic. Each PLC brand has its own programming software, so it is best to start with one and learn it step by step.

For learning purposes, choose a brand that provides student editions, trial versions, or free learning software. This allows you to practice PLC programming without investing in expensive hardware.

Below is a list of popular PLC software you can explore:

- Siemens – STEP 7, TIA Portal

- Allen-Bradley (AB) – Connected Components Workbench (CCW), Studio 5000, RSLogix 500

- Schneider Electric – Unity Pro, EcoStruxure Control Expert

- Delta – ISPSoft (Free)

- ABB – Automation Builder

- Honeywell – Experion & ControlEdge tools

- Panasonic – FPWIN Pro

Start with one software (for example Siemens TIA Portal or Allen-Bradley CCW) and focus on learning its environment, instructions, and simulation features. Once you are confident, you can easily explore other brands since most programming concepts are similar across PLCs.

Step 4 – Learn the Basics of PLC

Once you have selected your PLC brand and software, the next step is to understand the basic concepts of PLC. A PLC is not just about programming — it also involves knowledge of its hardware, software, wiring, and communication methods. This foundation will make your learning process much easier.

Important areas to focus on include:

- Digital Signals – On/Off signals (0 or 1) used for switches, push buttons, and relays.

- Analog Signals – Continuous signals (0–10 V, 4–20 mA) used for sensors like temperature, pressure, and flow.

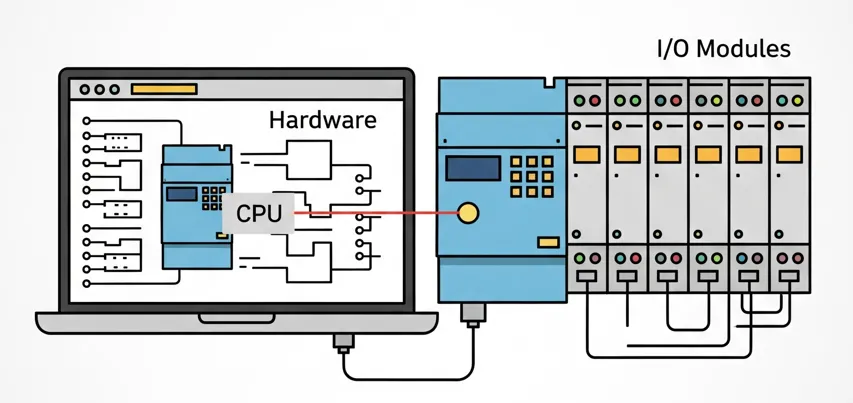

- PLC Hardware – CPU, input/output (I/O) modules, power supply, and communication modules.

- PLC Software – Programming environment such as TIA Portal, Studio 5000, or ISPSoft.

- Wiring & Connections – How sensors, switches, and actuators are connected to PLC input/output modules.

- Communication Protocols – Industrial protocols like Modbus, Profibus, Profinet, EtherNet/IP, and DeviceNet.

- HMI/SCADA Basics – How PLCs communicate with operator screens and supervisory systems.

By learning these basics, you will understand how a PLC interacts with the real world and other devices. This knowledge is essential before diving into programming and advanced automation projects.

Step 5 – Learn Ladder Logic Programming

After selecting your PLC software, the next step is to start learning Ladder Logic programming. Ladder Logic is the most common language used in PLCs because it looks similar to electrical relay diagrams, making it easy for engineers and technicians to understand.

Begin with simple programs and gradually move toward more complex logic. Focus on the following key concepts:

- Contacts and Coils – The building blocks of Ladder Logic (similar to switches and relays).

- Timers (TON, TOF, RTO) – Used for time delays, on/off control, and process sequencing.

- Counters (CTU, CTD) – For counting operations such as items on a conveyor or cycles in a process.

- Bit Instructions – Latch (Set/Reset), internal memory bits, interlocks, and flags.

- Comparison Instructions – Greater than, less than, equal, and other conditions to control logic.

- Math Functions – Basic addition, subtraction, multiplication, and division used in process control.

- Analog Scaling – Converting 4–20 mA or 0–10 V signals into engineering units.

Practice by writing small programs such as motor start/stop circuits, lamp blinking with timers, or counting objects using a sensor. Most PLC software provides a simulation mode, so you can test your programs without hardware.

Mastering Ladder Logic will give you the foundation to work on real industrial automation projects and prepare you for advanced topics like PID control and structured programming.

Step 6 – Practice with Simulation and Mini Projects

Learning theory is not enough — to truly understand PLC programming, you need hands-on practice. The best way to start is by using the simulation tools available in most PLC software. These simulators allow you to test your programs on a virtual PLC without needing expensive hardware.

Begin with small mini projects that represent real-world industrial applications. This will help you apply your knowledge of ladder logic, timers, counters, and analog instructions.

Example mini projects to try:

- Start/Stop motor control with interlocking.

- Blinking a lamp using a timer (TON/TOF).

- Conveyor belt system with a counter to count objects.

- Tank level monitoring using analog inputs and comparison instructions.

- Traffic light control sequence using timers.

- Temperature control simulation with RTD and analog scaling.

Working on such projects will help you build problem-solving skills and gain confidence. Later, you can connect your program to actual hardware kits or training modules to test it in real conditions. This step will prepare you for industrial projects and job interviews.