Counter Instructions In Panasonic Plc

Counter , Used For Counting Bit. Counter Count If Input Is Set To 1 Or Only True Logic. Counters Are Used Where Somthing Counts, In This Article You Will Learn About Counter Up, Counter Down, Counter Up/Down, Counter Block.

Codesys Counter Instruction

Counter Are Used For Counting Bit And Increment And Decrement Of Bits, Generally Two Type Of Counter Are Used Either UP Counter Or Down Counter.

Introduction To Siemens Counter Instructions

Counters Have Memory Area Reserved For Them In The Memory Of CPU. This Memory Area Reserves One 16-Bit Word For Each Counter Address. Set Counter Preset Value By Entering A Number From 0 To 999,

Rslogix 500 Counter Instructions

Counter Counts Inputs Bit When Bit Changes From 0 To 1 And Counts Are Increment Or Decrement By One Total No Of Count Value Is Stored On Counter Accumulator Value.

Omron PLC Counter Programming Instructions CX-Programmer

A Counter That Counts Input Pulses Or Events Count Maybe Up, Down Or Both . It's Depends On Type Of Counter. Counter Track An Events Of How Many Times Has Occurred. For Example Counter Used To Count How Many Products Produced Or Delivered. Counter Count When Input Pulse Change From True To False Or False To True. Than Compare The Result With Preset Value And Current Value. If Both Are Equal To Each Other Than Counter Process Is Completed. In Omron Plc Counter Are Generally Two Type Binary And Bcd Counter And Than Sub Classified As Following

Connected Components Workbench Micro800 Counter Instructions

Counter Instructions Use To Control Operations Based On The Number Of Events. Counter Counts Input Bit Of Counter And Increment Or Decrement By 1 When Input Bit Of Counter Change. A Counter Input Bit Is Pulses Or Events. Increment Counter Is Known As Count Up And Decrement Counter Known As Count Down.

Fuji PLC Counter Instruction

Counter Counts Input Bit Of Counter And Increment Or Decrement By 1 When Input Bit Of Counter Change. A Counter Use For Counting Of Event, Pulses And Sequences. A Counter Input Is Always Is Bit (ON Or OFF), Pulses Or Events. Increment Counter Which Increment Its Preset Value When Input Bit Is Change From True To False, Decrement Counter Decrement Preset Value When Input Is Change From True To False. In Fuji PLC Have Two Type Of Counter , Counter UP And Counter Down.

B&R Automation Studio Counter Function Blocks Programming | CTU | CTD | CTUD

Counter Instructions Use To Counts Input Bit Of Counter By Increment Or Decrement By 1 Of Counter Value, When Input Bit Of Counter Changes From True To False.

B&R Automation Studio Counter Function Blocks Programming In ANSI C | CTU | CTD | CTUD

Up Counter Increments Counter Value By 1. Downward Counter Decrement Counter Value By 1. In ANSI C Programming You Can Use Counter As Function Statement. So First Declare Counters Function In A Programming Than You Can Use Their Parameter

Mitsubishi FX Series Counter Instructions: Mitsubishi PLC Programming with Counter, High speed Counter and Bi-directional Counters

A Counter count input bit generally we have a two type of counter up counter which is a incremental counter it increment current value of counter when input bit is set to ON. Second counter is decrement counter it decrement value by 1 when input bit is changed from off to ON. another counter is up/down counter,

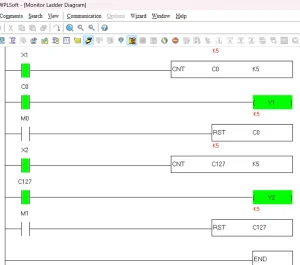

Introduction to DELTA PLC Counter

In Delta Plc counter is a important instruction in PLC. in delta plc have two types of counter CNT is 16 bit Counter instruction. DCNTis 32 bit counter instruction. counter increment or decrement current value by 1 each time when input of counter is changed from OFF to ON.

ABB PLC Counter : CTU, CTD and CTUD

ABB PLC have up counter CTU, Down counter CTD and up down counter CTUD. counter increment or decrement counter current value when input of counter is changed from false to true or OFF to ON.

ABB Functional Block Diagram Counter Blocks - CTU, CTD and CTUD

functional block diagram have up counter, down counter and up down counter blocks. up counter is an incremental counter, down counter is a decremented counter and up down counter perform both action when particular counter input bit is set. up counter and down counter have fixed input and output.

Delta PLC Counter Instructions: Low-Speed CNT and High-Speed DCNT

Learn the difference between CNT (low-speed counter) and DCNT (high-speed counter) in Delta PLC using WPLSoft or ISPSoft. Explore practical use cases, device addressing, timing behavior, and application guidelines.

Delta PLC Counter Instructions in AH Series PLC: Understanding CNT and DCNT Functions

Learn how to use CNT and DCNT instructions in Delta AH Series PLCs. Understand the working of 16-bit and 32-bit counters, including counting direction, preset values, and auxiliary bit control for general-purpose and high-speed applications.

RSLogix 5000 Counter Instruction – CTU, CTD, RES with Examples

Learn how to use RSLogix 5000 counter instructions like CTU (Count Up), CTD (Count Down), and RES (Reset). Understand their parameters, working logic, and real-world applications in Allen Bradley PLCs.

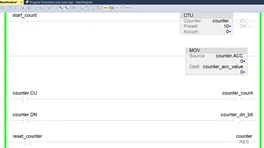

Schneider PLC Counter Programming in EcoStruxure Control Expert

Learn how to program counters in Schneider Electric PLCs using EcoStruxure Control Expert. This step-by-step guide covers Up Counter, Down Counter, and Reset Counter instructions with practical examples for beginners and professionals.

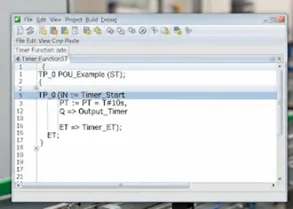

Timer in Structured Text (ST) Programming – Schneider PLC EcoStruxure Control Expert

Learn how to program timers in Structured Text (ST) using Schneider PLC EcoStruxure Control Expert. Understand TON, TOF, and TP timers with examples, applications, and best practices for industrial automation.