DOL Starter – Working Principle, Wiring Diagram, Components & Applications

Published on July 4, 2024 | Category: DOLShare this Page:

A Direct-On-Line (DOL) starter is the simplest and most commonly used method for starting 3-phase induction motors. It directly connects the motor terminals to the power supply using a contactor and overload relay. DOL starters are known for their simplicity, cost-effectiveness, and ease of installation, making them highly suitable for small motors with low starting current requirements.

This starter connects the motor directly to the power supply without reducing the starting voltage. While this method is effective for smaller motors, it results in a high inrush current—typically 6 to 8 times the rated current—which can cause voltage dips in the power system. Hence, DOL starters are not suitable for larger motors or weak electrical systems.

A motor starter, in general, is an essential electrical device used to start, control, and protect electric motors. It regulates the initial inrush current and provides protection against overloads, phase failures, and short circuits. Motor starters are extensively used in industrial, commercial, and residential settings to enhance motor performance, operational safety, and lifespan.

What is DOL Starter in Motor?

A Direct-On-Line (DOL) starter is the most basic and cost-effective method for starting a 3-phase squirrel cage induction motor. As the name suggests, it connects the motor terminals directly to the full line voltage of the power supply without any voltage reduction during startup. This approach delivers maximum starting torque, which is advantageous for applications where a motor needs to overcome initial inertia quickly.

However, this method also results in a very high inrush current—typically 6 to 8 times the motor’s rated current—which can lead to voltage dips and mechanical stress on the motor and connected load. Due to this limitation, DOL starters are generally suitable only for motors with smaller ratings (typically less than 5 HP or 3.75 kW), where the high starting current does not negatively affect the electrical supply network.

Working Principle of DOL Starter

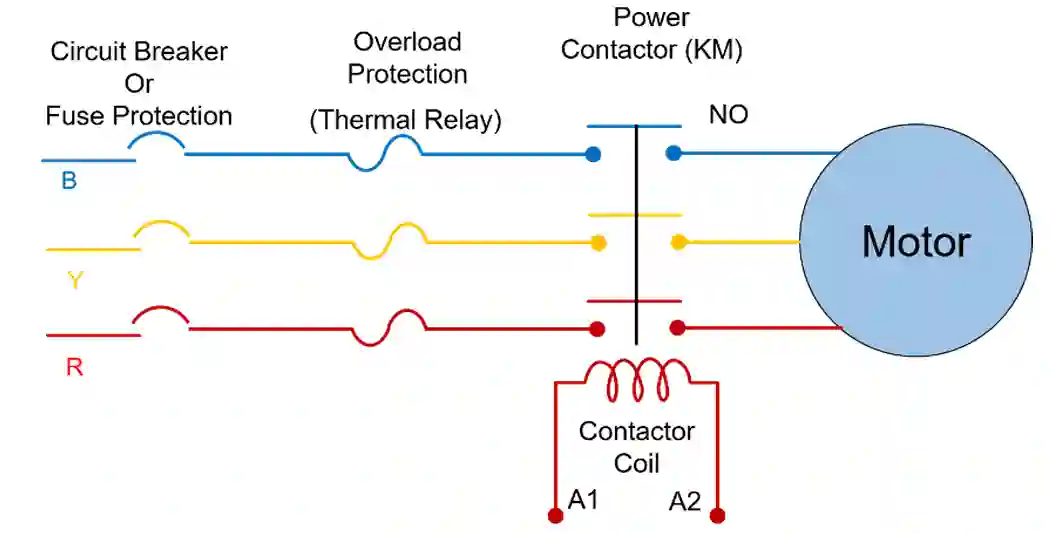

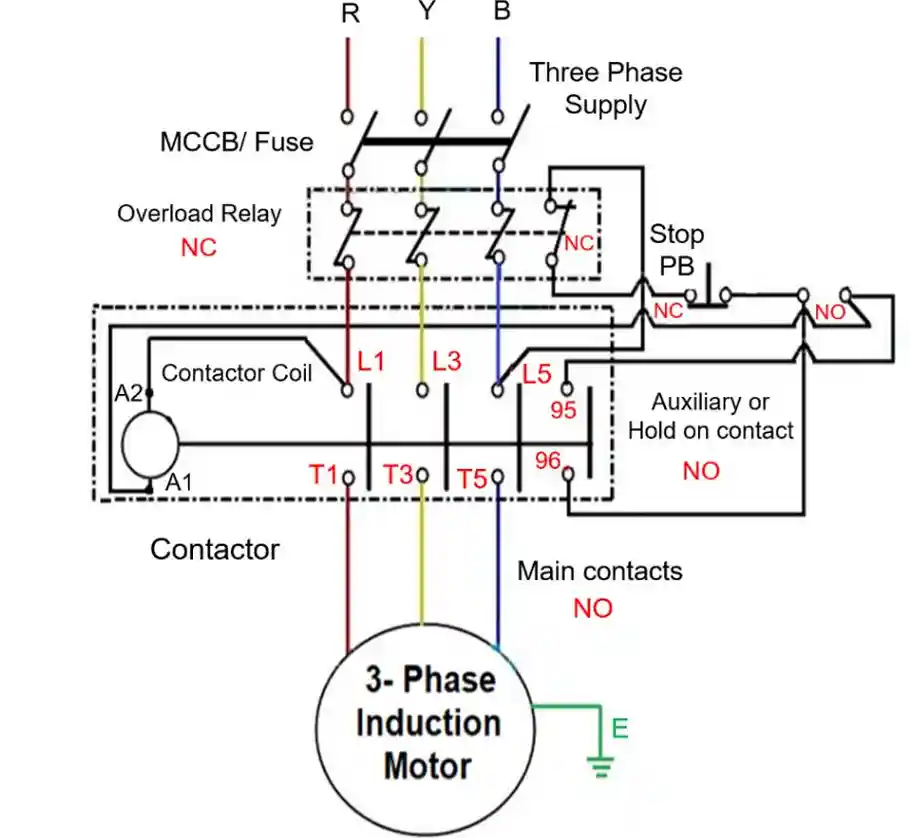

The DOL (Direct-On-Line) starter works on a simple principle: it connects the motor directly to the full supply voltage. The system is divided into two main parts — the Power Unit and the Control Unit. Together, these units ensure the safe and effective operation of the motor.

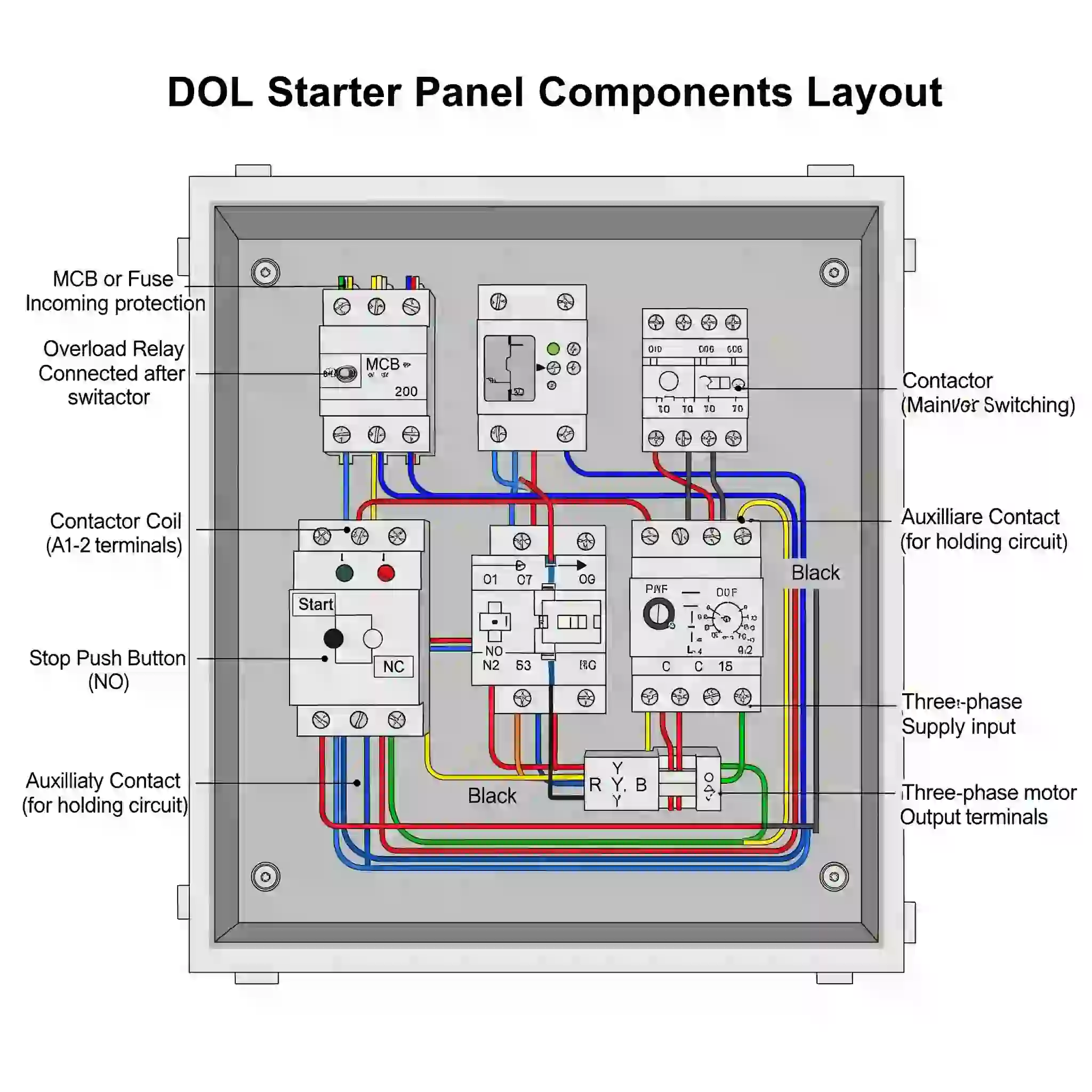

1. Power Unit of DOL Starter

The power unit is responsible for delivering electrical power to the motor. It connects the motor directly to the three-phase AC supply without any voltage reduction during startup. This unit consists of:

- MCB or Fuse: Provides short circuit protection to the system.

- Contactor (Main Contacts): Acts as a switching device to connect or disconnect power to the motor.

- Overload Thermal Relay: Protects the motor from overheating due to overload by disconnecting the supply.

These components are wired in series and ensure that the motor receives the necessary voltage and current for operation while protecting it from electrical faults.

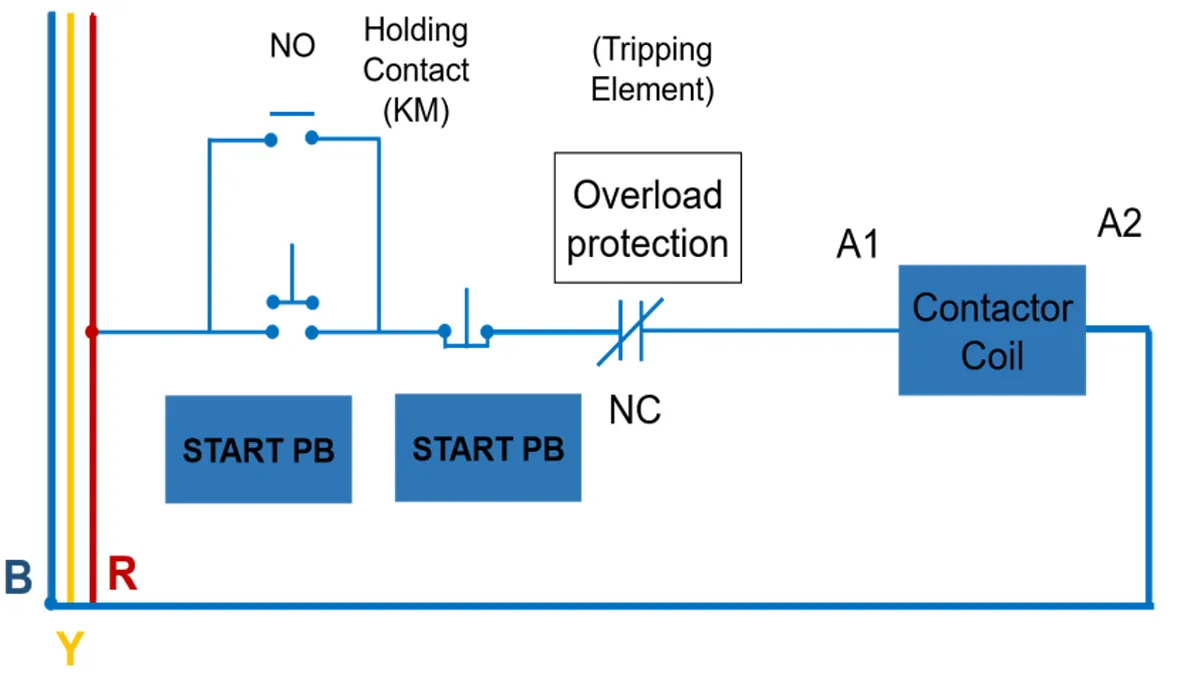

2. Control Unit of DOL Starter

The control unit manages the switching operation of the contactor and allows the user to start or stop the motor as needed. It also ensures safety during abnormal conditions like overload. This unit typically includes:

- Start Push Button (NO – Normally Open): When pressed, it energizes the contactor coil to start the motor.

- Stop Push Button (NC – Normally Closed): When pressed, it de-energizes the coil to stop the motor.

- Contactor Coil: Electromagnetic coil that pulls the contactor contacts together when energized.

- Auxiliary Contact (Holding Contact): Maintains the circuit after the start button is released.

- Overload Relay Contact: Interrupts the control circuit if an overload condition is detected.

The control circuit operates at a lower voltage (typically 24V, 110V, or 230V) for safety and is independent of the power circuit. It automates the motor start/stop process and ensures protection from abnormal conditions.

Together, the power and control units make the DOL starter an effective and reliable method for starting small motors directly from the power supply.

The DOL starter includes essential components such as a contactor, overload relay, and sometimes a start/stop push button station. It provides basic motor protection against overload and short circuits, but it does not reduce starting current. For larger motors or more sensitive systems, advanced starters like star-delta or soft starters are preferred.

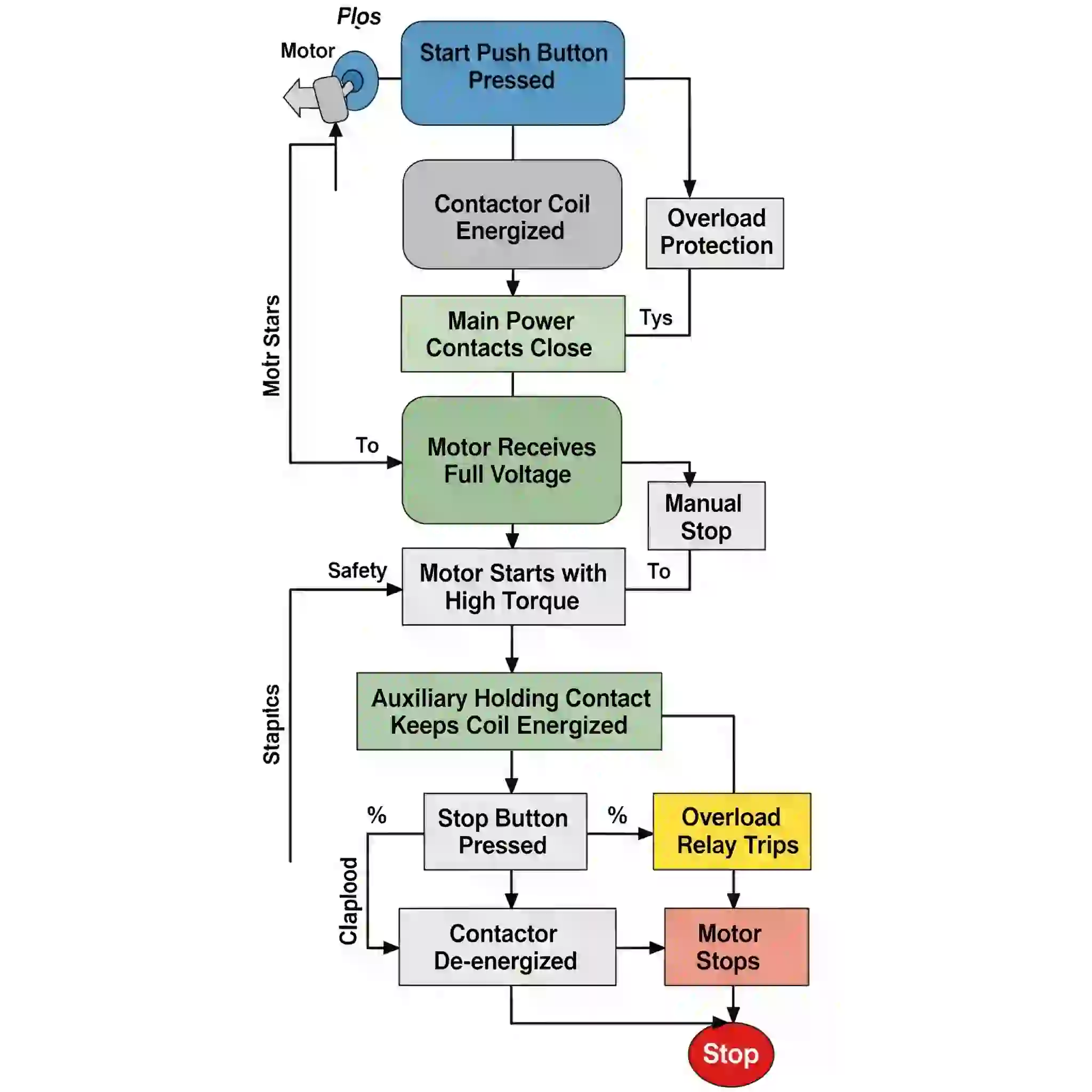

Step-by-Step DOL Starter Working Process

The Direct-On-Line (DOL) starter provides a straightforward and effective way to start motors by connecting them directly to the power supply. The following sequence outlines the complete operation:

1. Motor Start Operation

- The operator presses the Start push button, completing the control circuit.

- The contactor coil (A1–A2) is energized, closing the main power contacts.

- The motor receives full line voltage and starts running with maximum torque.

2. Motor Running Condition

- Once the start button is released, the current continues to flow through an auxiliary holding contact.

- This keeps the contactor coil energized and the motor remains operational.

3. Motor Stopping Condition

- When the Stop push button is pressed, or if the overload relay detects an overcurrent, the control circuit opens.

- This de-energizes the contactor coil, which opens the main and holding contacts.

- The motor is disconnected from the power supply and comes to a stop.

This operation ensures safe control and protection of the motor using a simple push-button mechanism and basic electromechanical components.

DOL Starter Working Flowchart

The flowchart above summarizes the logic of DOL starter operation — from pressing the start button to stopping the motor under normal or fault conditions.

What is a DOL used for?

The need for a motor starter arises from the specific requirements and challenges associated with operating electric motors. Below are the main reasons why motor starters are essential in electrical and industrial systems:

- Control: The starter performs the control function by starting and stopping the motor through the opening and closing of the power circuit using contactors.

- Reduce High Starting Current: At startup, motors draw 6 to 8 times their normal current. A motor starter helps limit this inrush current, preventing damage to windings and reducing stress on the power system.

- Motor Protection from Electrical Faults: Starters protect motors from conditions like overload, short circuits, phase failure, under-voltage, and reverse phasing by monitoring current and voltage and disconnecting power when necessary.

- Smooth Operation: Starters ensure smooth starting, stopping, and reversing of motors, minimizing mechanical shocks to components like belts, gears, and shafts.

- Extended Equipment Lifespan: By reducing both electrical and mechanical stress, motor starters help extend motor life and lower maintenance costs.

Various Protection of Motor by Starter

A motor starter provides protection to the motor and the connected system by safeguarding it against various electrical and mechanical risks. Below are the key protection features offered by a motor starter:

- Overload Protection:

- Monitors the motor's current and disconnects the power if it exceeds a set threshold for a specific duration.

- Prevents overheating of motor windings due to continuous overload.

- Typically achieved using thermal or electronic overload relays.

- Short Circuit Protection:

- Detects excessive current due to short circuits and instantly disconnects the motor.

- Uses devices like fuses, MCBs (Miniature Circuit Breakers), or MCCBs (Moulded Case Circuit Breakers).

- Phase Failure Protection:

- Identifies the loss of one or more phases in a 3-phase system.

- Prevents unbalanced currents and overheating by shutting down the motor.

- Under-voltage Protection:

- Monitors voltage levels to avoid motor operation under low voltage conditions.

- Prevents torque loss and overheating by stopping the motor when voltage drops below a safe level.

- Restarts the motor only when voltage returns to normal range (usually a fixed percentage of rated voltage).

- Reverse Phase Protection:

- Detects incorrect phase sequence or reverse motor rotation.

- Prevents motor damage and ensures equipment functions correctly.

- Earth Fault Protection:

- Detects insulation failure or leakage current to the ground.

- Disconnects power to avoid damage and ensure personnel safety.

- Overheating Protection:

- Uses thermistors or temperature sensors to monitor the motor's internal temperature.

- Shuts down the motor if overheating is detected to prevent thermal damage.

- Mechanical Protection:

- Minimizes mechanical stress during start and stop operations.

- Protects connected components like gears and belts from sudden torque changes.

These protective features make motor starters essential for the safe, reliable, and efficient operation of motors in industrial and commercial applications.

Advantages, Disadvantages, and Applications of DOL Starter

Advantages of DOL Starter

- Cost-effective and economical compared to other motor starters.

- Simple design and easy to operate.

- Simplest control circuit among all types of starters.

- Provides high starting torque which is beneficial for starting loads with inertia.

- Easy to maintain and troubleshoot due to minimal components.

- Suitable for motors connected in delta configuration at terminal box.

Disadvantages of DOL Starter

- Does not reduce the high inrush starting current.

- High starting current can lead to voltage dips in weak supply systems.

- Increased mechanical and thermal stress reduces motor and load life.

- High starting torque may cause a sudden jerk, potentially damaging connected equipment.

Applications of DOL Starter

DOL starters are commonly used in applications involving small motors where the supply system can handle high inrush currents. Typical applications include:

- Water pumps

- Air compressors

- Conveyor belts

- Blowers and fans

- Machine tools