What is a Soft Starter for Motor? Working Principle, Applications, and Uses

Published on July 8, 2024 | Category: Soft-StarterShare this Page:

A soft starter is an advanced motor control device designed to provide a smooth and controlled start-up of induction motors by gradually increasing the supply voltage. This soft starting technique significantly minimizes both mechanical stress and electrical surges that typically occur during motor startup. Unlike traditional direct-on-line (DOL) starters, which apply full voltage instantly, soft starters ensure a jerk-free acceleration by linearly ramping the voltage from zero to the rated level. This voltage ramping is achieved through the controlled firing of thyristors, which form the core of soft starter construction.

One of the primary advantages of using a soft starter is its ability to reduce inrush current and limit peak electrical demand during motor startup. This not only protects the motor windings and connected mechanical systems such as belts, gears, or pumps but also enhances the overall reliability and lifespan of the equipment. Additionally, most soft starters come with site-configurable parameters, allowing users to adjust performance based on specific load and operational requirements.

A common misconception is that soft starters contribute to harmonic distortion in the electrical network. However, during normal motor operation, a bypass contactor is engaged, allowing current to flow through a low-resistance path and effectively bypassing the thyristors. This ensures that soft starters have minimal to no impact on system harmonics during continuous running.

Unlike Variable Frequency Drives (VFDs), which can control both the speed and torque of a motor throughout its operation, soft starters are primarily intended for smooth acceleration and deceleration. They are ideal for applications where full-speed operation is sufficient after start-up. From industrial machinery to HVAC systems and water pumps, soft starters are widely used in both commercial and industrial environments for efficient and secure motor management.

Schneider, ABB, AB, Siemens and other leading manufacturers offer comprehensive ranges of soft starter solutions that meet diverse performance, safety, and installation needs. These devices ensure not only operational safety and energy efficiency but also simplify system integration with features such as fast wiring, easy setup, and reliable protection of both equipment and personnel.

What is a Soft Starter?

A soft starter is an electronic device used to smoothly start and stop electric motors. Unlike traditional motor starters like direct-on-line (DOL) or star-delta starters, a soft starter gradually increases the voltage supplied to the motor using electronic components called thyristors. This soft ramp-up of voltage reduces the initial inrush current and the mechanical shock on the motor and connected equipment.

During startup, the voltage starts at a very low level. At this stage, the motor only generates enough torque to eliminate slack in gearboxes, stretch belts or chains, and prepare the machine for rotation. As voltage increases gradually, the motor begins to accelerate smoothly without sudden jerks. This protects both the motor and the mechanical system from unnecessary stress and wear.

One of the biggest advantages of a soft starter is that it allows users to adjust the starting torque based on the application’s load. Whether the motor is starting under full load or no load, the torque can be optimized for smoother performance and lower maintenance requirements. The result is longer equipment life and reduced downtime.

In addition to smooth starting, soft starters often include a soft stop function. This is especially useful in applications like water pumps, where an immediate stop could cause water hammer in the pipeline. By decelerating the motor gradually, the soft stop prevents pressure surges and pipe damage. It is also helpful in conveyor belt systems, where sudden stops could cause the material to spill or get damaged.

Overall, soft starters provide a reliable and efficient solution for reducing electrical and mechanical stress during motor startup and shutdown, making them ideal for pumps, fans, conveyors, compressors, and other industrial equipment.

Working Principle of Soft Starter

A soft starter is an electrical device that controls the acceleration and deceleration of an electric motor by gradually increasing or decreasing the voltage. It helps reduce the inrush current and mechanical stress on the motor and connected equipment during startup and stopping.

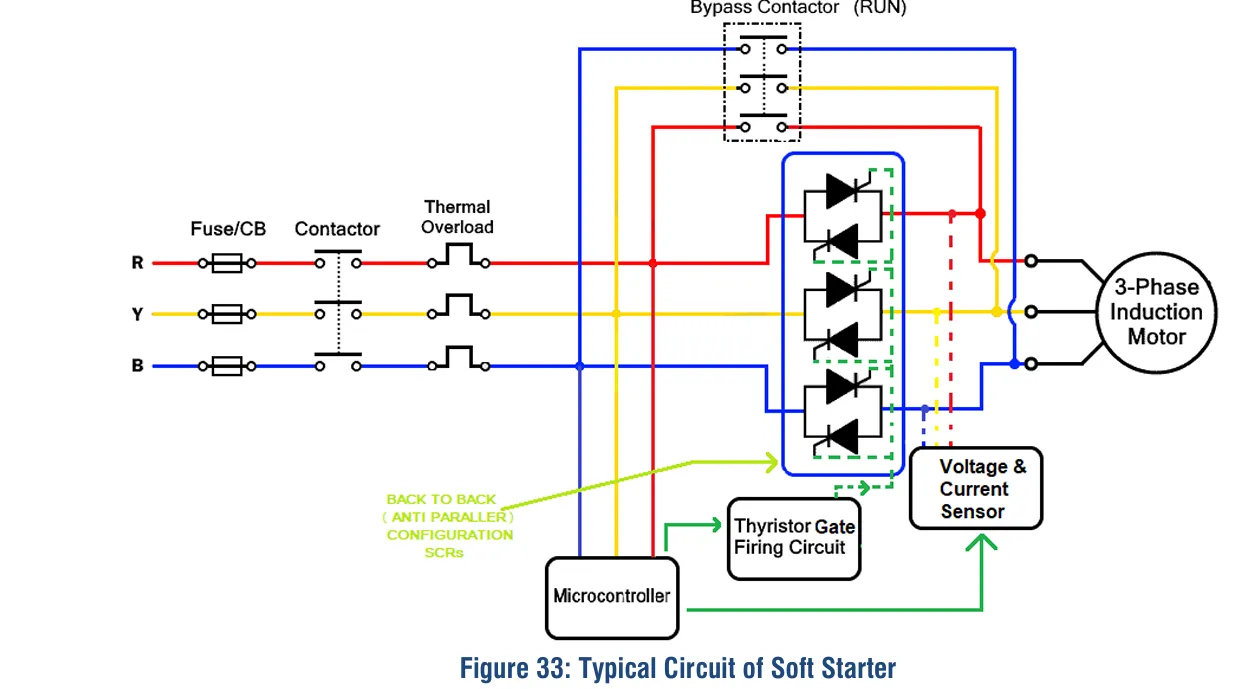

The working of a soft starter is based on two main parts: the Power Circuit and the Control Circuit, which work together to ensure safe and smooth motor operation.

Power Circuit

The power circuit delivers electrical energy from the power supply to the motor. It includes:

- MCB/MCCB or Fuse: Protects the system from overcurrent and short-circuits.

- Thyristors (SCRs): These are semiconductor switches that control the voltage sent to the motor. Initially, they allow only a small part of the voltage to pass, reducing motor torque. As the motor ramps up, the voltage gradually increases until it reaches full power.

- Overload Relay: Monitors motor current and disconnects the supply if the current exceeds safe limits.

- Bypass Contactor: Once the motor reaches full speed, this contactor takes over from the thyristors to improve efficiency and reduce heat.

- Heat Sink and Cooling Fans: These remove the heat generated during the voltage ramp-up phase.

Control Circuit

The control circuit manages how and when the power is applied to the motor. It includes:

- Start and Stop Push Buttons: Manual control to initiate or stop the motor.

- Microcontroller or Logic Unit: Sends control signals to the thyristors to gradually increase the voltage.

- SCR Triggering Circuit: Controls how much of the AC voltage is allowed through the SCRs at each moment.

- Auxiliary Contacts: Maintain the circuit and enable interlocking features.

- Sensors and Protection Units: Monitor current, voltage, phase loss, or overheating to protect the motor.

When the motor is started, the control circuit activates the thyristors with a small voltage. This allows the motor to begin turning slowly and smoothly. Over a few seconds (called the ramp time), the voltage increases gradually, reducing mechanical stress and avoiding sudden jerks. Once full speed is reached, the bypass contactor closes, and the motor runs efficiently.

During stopping (if soft stop is enabled), the voltage is again reduced gradually instead of being cut off instantly. This smooth stop is useful in applications like pumps and conveyors where sudden stops may cause damage.

In summary, a soft starter works by smoothly controlling the voltage supplied to the motor using thyristors and a smart control system. This not only protects the motor and connected load but also increases operational life, reduces maintenance, and improves energy efficiency.

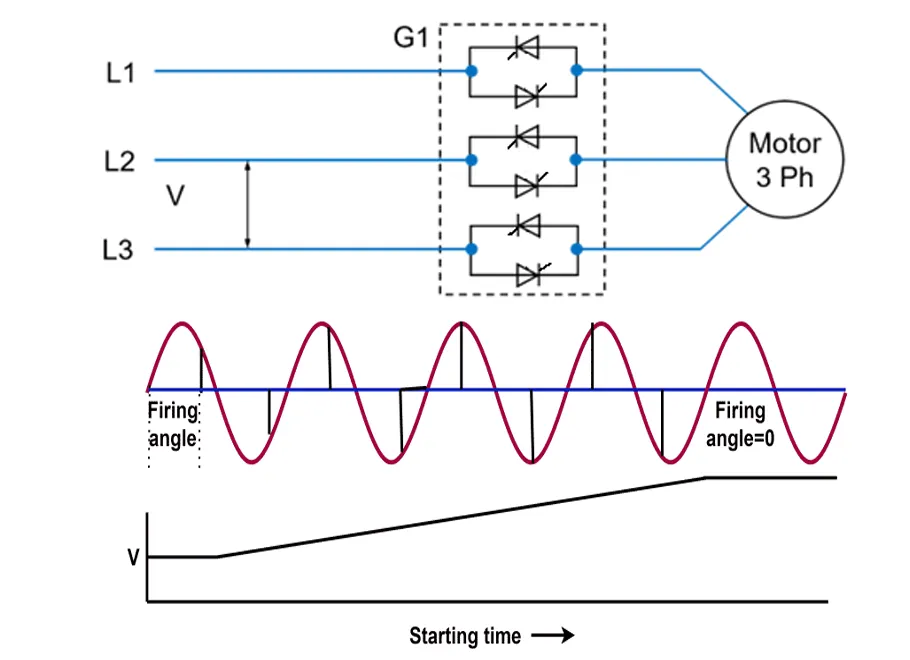

How a Soft Starter Controls Voltage During Motor Start

A soft starter helps a motor start smoothly by slowly increasing the voltage from zero to full level. This avoids a sudden flow of high current and reduces stress on the motor and connected equipment. The soft starter uses electronic components to control how much voltage is sent to the motor at each moment.

When the motor is first turned on, it receives only a small amount of voltage. This allows it to start gently without sudden jerks or high torque. As the motor picks up speed, the soft starter gradually increases the voltage until it reaches the full supply level.

This gradual process protects the motor from overheating and helps extend its life. It also avoids voltage drops in the power system, which can happen with traditional direct-on-line (DOL) starting methods.

When stopping the motor, the soft starter can reduce the voltage slowly, helping the motor stop gently. This is useful in systems like pumps or conveyors, where a sudden stop could cause damage or splashing.

In short, a soft starter controls how quickly voltage is applied or removed during motor start and stop. This makes motor operation safer, smoother, and more reliable.

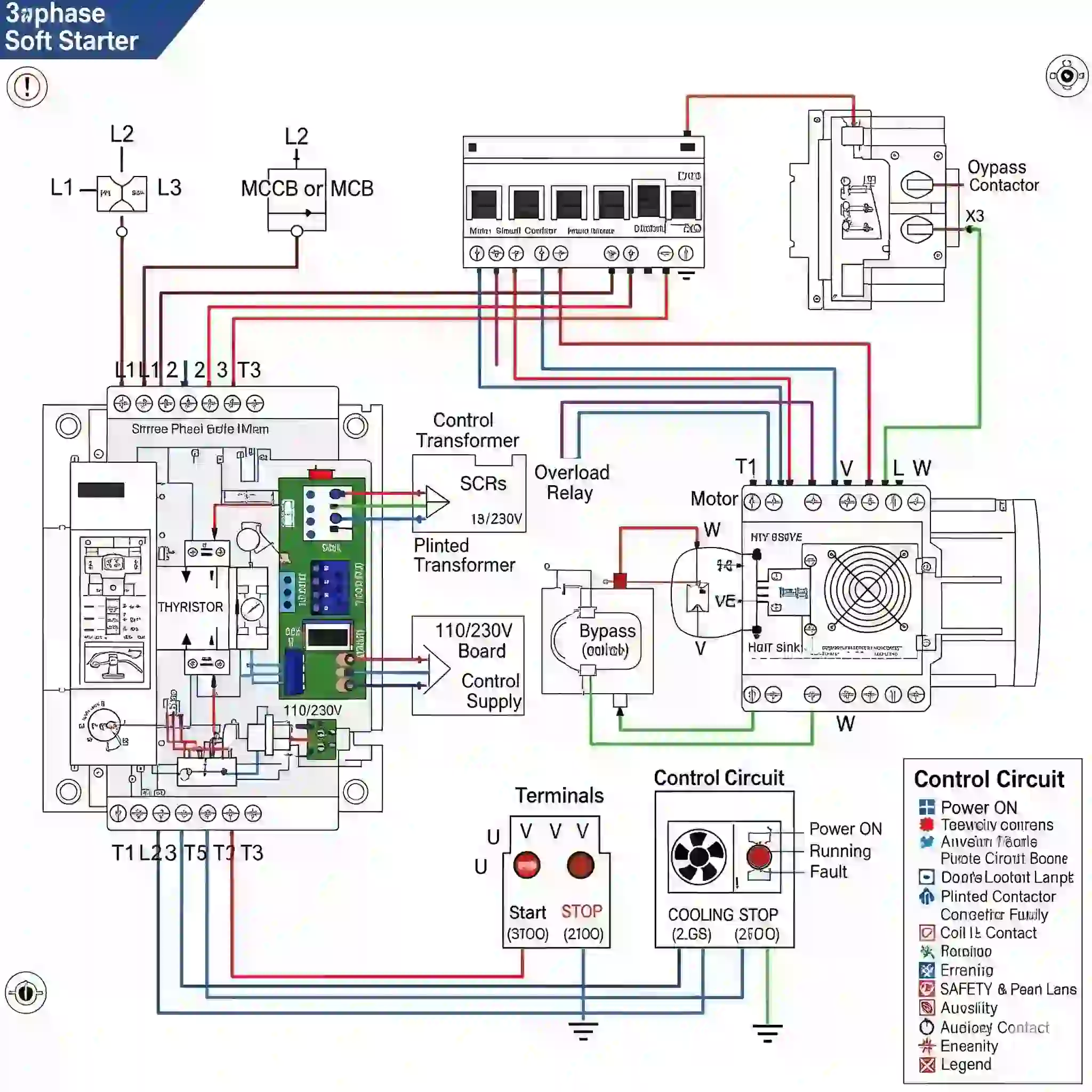

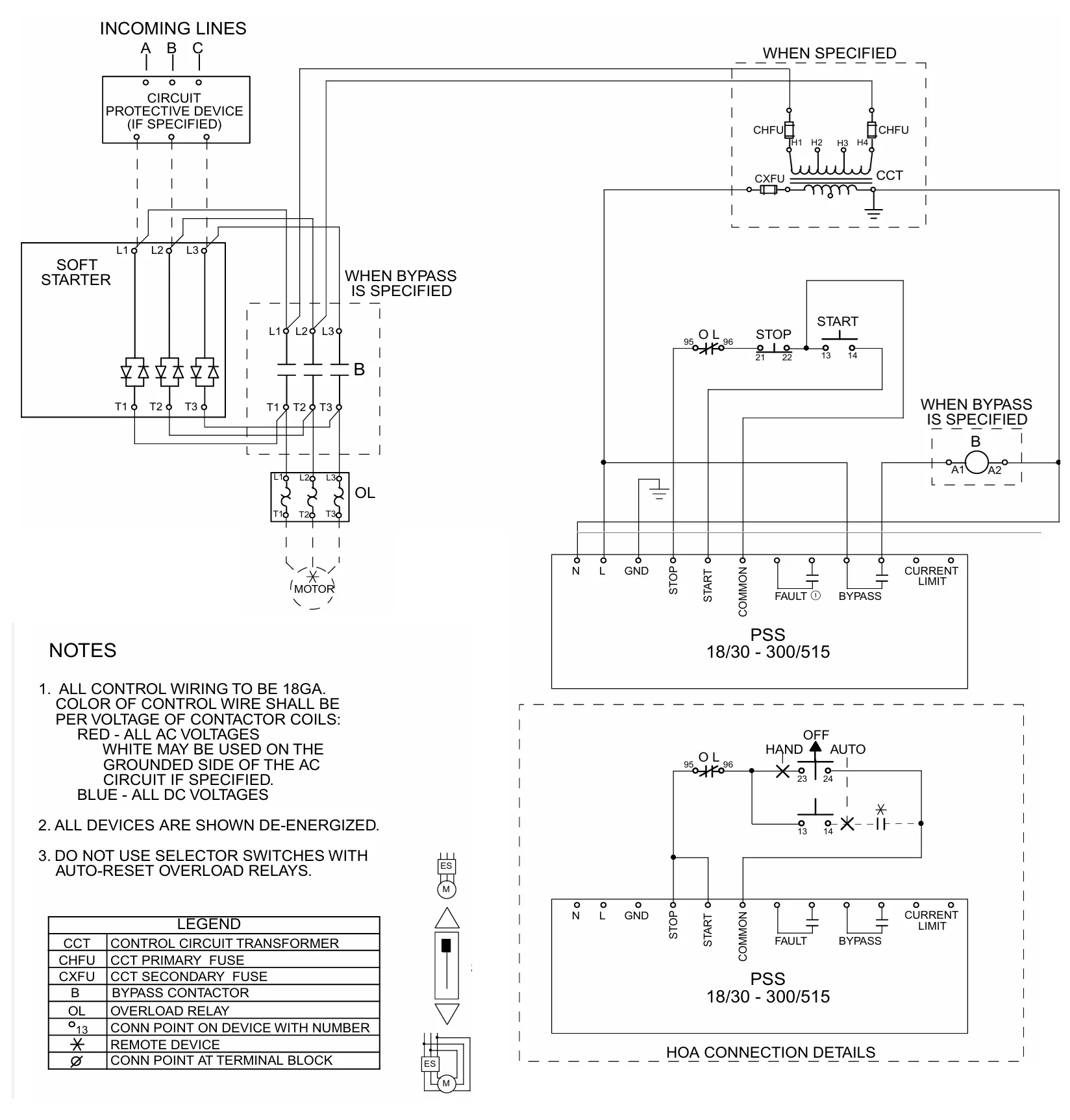

Soft Starter Wiring Diagram with Control and Bypass Circuit

This wiring diagram represents a complete three-phase soft starter setup, including both power and control circuits. It shows how the motor is safely started using thyristors, protected via overload relays, and optionally bypassed for energy efficiency.

Power Circuit Description

- Incoming Lines (A, B, C): Three-phase supply enters the system through protective devices like fuses or circuit breakers.

- Soft Starter Terminals (L1, L2, L3 → T1, T2, T3): Voltage passes through the soft starter, which uses thyristors to gradually apply voltage to the motor.

- Overload Relay (OL): Connected after the soft starter, it trips in case of prolonged overcurrent conditions to protect the motor.

- Motor: The three-phase motor is connected at the output terminals (T1, T2, T3) and receives voltage as ramped up by the soft starter.

Bypass Circuit (When Specified)

- Bypass Contactor (B): Once the motor reaches full speed, this contactor closes to bypass the thyristors and reduce heat generation.

- Contactor Coil (A1-A2): Energizes the bypass contactor when needed.

Control Circuit Description

- Control Power Supply (N, L, GND): Supplies AC voltage to operate the soft starter’s internal control logic.

- Start and Stop Push Buttons: Wired to terminal strips. Pressing Start initiates the soft start process; pressing Stop interrupts it.

- Overload Relay Contacts (95-96): Normally closed contacts that open in case of overload, cutting off control power to stop the motor.

- Status Terminals: Dedicated outputs for monitoring Fault, Bypass, and Current Limit, used for indicators or automation feedback.

HOA (Hand-Off-Auto) Switch Wiring

The Hand-Off-Auto switch allows for different control modes:

- Hand: Motor is started manually via the Start button.

- Auto: Motor start/stop is controlled by an external signal or PLC.

- Off: Disables all start commands for safe shutdown and servicing.

HOA wiring includes safety interlocks and feedback mechanisms to ensure correct mode operation.

Wiring Notes

- All control wiring should use 18 AWG wire.

- Color coding:

- Red for all AC voltages

- White for grounded AC return (if required)

- Blue for DC voltages

- Always ensure the panel is de-energized before servicing.

- Do not use selector switches with auto-reset overload relays unless specified.

Legend

- CCT: Control Circuit Transformer

- CHFU: Primary fuse of the control circuit

- CXFU: Secondary fuse of the control circuit

- B: Bypass Contactor

- OL: Overload Relay

- Ø: Terminal connection point

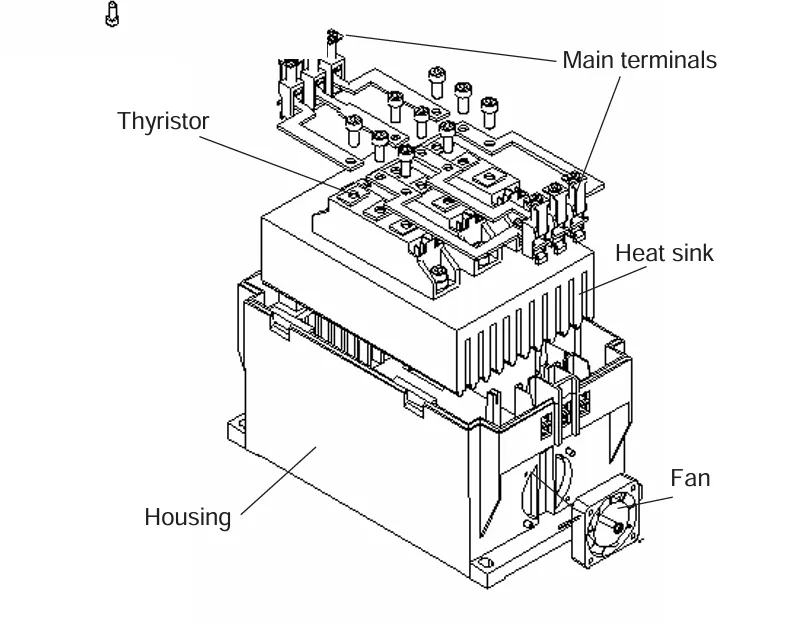

Components and Features of a Soft Starter

A soft starter contains various essential components that work together to control the motor during starting and stopping. These components ensure safe, smooth, and energy-efficient operation, especially for industrial motors. Below are the key parts of a soft starter and their functions:

1. Printed Circuit Board (PCB)

The PCB is the control center of the soft starter. It handles logic functions like calculating motor parameters (such as active power, power factor, and current) and controls the switching of the thyristors. It may also store event logs, display trends, and monitor historical motor data to support predictive maintenance.

2. Thyristors (SCRs)

Thyristors are semiconductors placed in two or three phases of the power circuit. They control the voltage sent to the motor during startup and soft stop. By adjusting their conduction, the voltage is gradually increased or decreased. Once the motor reaches full speed, the thyristors conduct fully or are bypassed for efficiency.

3. Heat Sink

The heat sink helps to remove heat generated by the thyristors during operation. Its size determines how much current the soft starter can handle and how often it can start the motor. Larger heat sinks allow for higher starting capacity and better cooling performance.

4. Cooling Fans

Fans are used to increase the cooling effect of the heat sink. Depending on the soft starter’s size and design, it may have one, two, or more fans. Smaller soft starters may not use fans, which limits their ability to start motors frequently.

5. Housing

The outer body or housing protects the internal components from dust, dirt, and physical damage. It is usually made of plastic, metal, or both. However, many soft starters require additional enclosures if installed in harsh environments to meet the desired protection class (e.g., IP54 or IP65).

6. Communication and Control Circuits

Soft starters often include digital or analog control systems that may be programmable. These circuits allow integration with industrial systems using communication protocols like Modbus, Profibus, DeviceNet, Interbus-S, and LONWorks. These features support remote monitoring, alarms, and smooth coordination with SCADA or PLC systems.

7. Electronic Overload Relay (EOL)

Instead of traditional bimetal overload relays, modern soft starters use electronic overload relays. EOLs measure current electronically and provide more accurate and responsive protection, especially in applications where load conditions change frequently.

All these components work together to ensure smooth voltage control, motor protection, and compatibility with modern industrial automation systems.

Soft Starter Settings: Parameters, Functions, and Practical Uses

Soft starters offer a wide range of configurable parameters that help manage how motors start, stop, and operate. These settings can be adjusted through potentiometers, DIP switches, keypads, or software depending on the soft starter model and manufacturer. Properly setting these parameters ensures motor protection, energy efficiency, and smooth mechanical operation.

1. Start Ramp Time

The start ramp defines the time it takes for the voltage to rise from the initial level to the full supply voltage when starting the motor. A gradual ramp ensures the motor starts smoothly without jerks. However, if the ramp time is too long, it may cause unnecessary heating and even trip the overload relay. For lightly loaded motors, the actual start time may be shorter than the ramp, while for heavy loads, it may take longer.

2. Stop Ramp Time

The stop ramp controls how slowly the voltage reduces when stopping the motor. It is especially useful for systems like pumps or conveyors where a smooth stop prevents mechanical shocks. If set to zero, the motor stops suddenly like a direct stop.

3. Initial Voltage (Uini)

This is the voltage level from which the soft starter begins its start or stop ramp. Also called "pedestrian voltage" or "initial torque," it determines the torque available at motor startup. Since torque is proportional to the square of voltage, too low a setting (e.g., 20%) will result in only 4% torque, which may not be enough to start the motor. Set it high enough to ensure the motor starts instantly without delay or overheating.

4. Current Limit

This setting limits the maximum current drawn by the motor during startup. It's useful for applications requiring low inrush current or for heavy-duty starts where voltage ramp and initial voltage are not enough. If the current hits the set limit, the soft starter pauses voltage increase until the current drops, then resumes ramping.

5. Step Down Voltage (USD)

Step down voltage is a special stop setting. It allows the voltage to quickly drop to a fixed lower level when stopping the motor. This makes the motor begin slowing immediately, even under light loads, and is particularly useful in pumping systems to avoid issues like water hammer.

6. Rated Motor Current

This setting allows you to input the motor’s rated current as per its nameplate. It affects how the soft starter calculates trip levels for the electronic overload relay, applies current limiting, and performs motor protection. Setting this correctly is crucial for safe operation.

7. Kickstart

Kickstart is a brief boost of higher voltage at the very beginning of motor startup. It helps overcome high static friction in loads like conveyor belts or piston pumps. After the kick, the normal ramp begins.

8. Bypass Contactor Control

Many soft starters have an internal or external bypass contactor that activates after the motor reaches full speed. This reduces heat and power loss by taking the thyristors out of the circuit during continuous operation. Settings may include the delay time and activation logic.

9. Motor Stop Mode

Some soft starters allow you to choose between different stop modes such as coast to stop (free run), soft stop (voltage ramp down), or DC braking (in advanced models). This helps match the motor stop behavior with the application.

10. Protection Trip Settings

You can configure trip levels for motor protections like overload, phase loss, under-voltage, stall, or locked rotor. Each setting allows the soft starter to react appropriately and disconnect the motor if necessary to prevent damage.

11. Communication Settings

If the soft starter supports industrial protocols (Modbus, Profibus, etc.), you can set communication parameters such as baud rate, slave ID, and timeout. These are essential for integration with SCADA or PLC systems.

12. Event Logging and Display

Advanced soft starters allow configuration of display screens, alarm logs, and event history. These logs help diagnose faults and support maintenance activities.

Setting the correct parameters in a soft starter not only ensures reliable motor performance but also reduces downtime, improves energy efficiency, and protects the entire system. Always refer to the motor's nameplate data and the soft starter's manual before configuring.

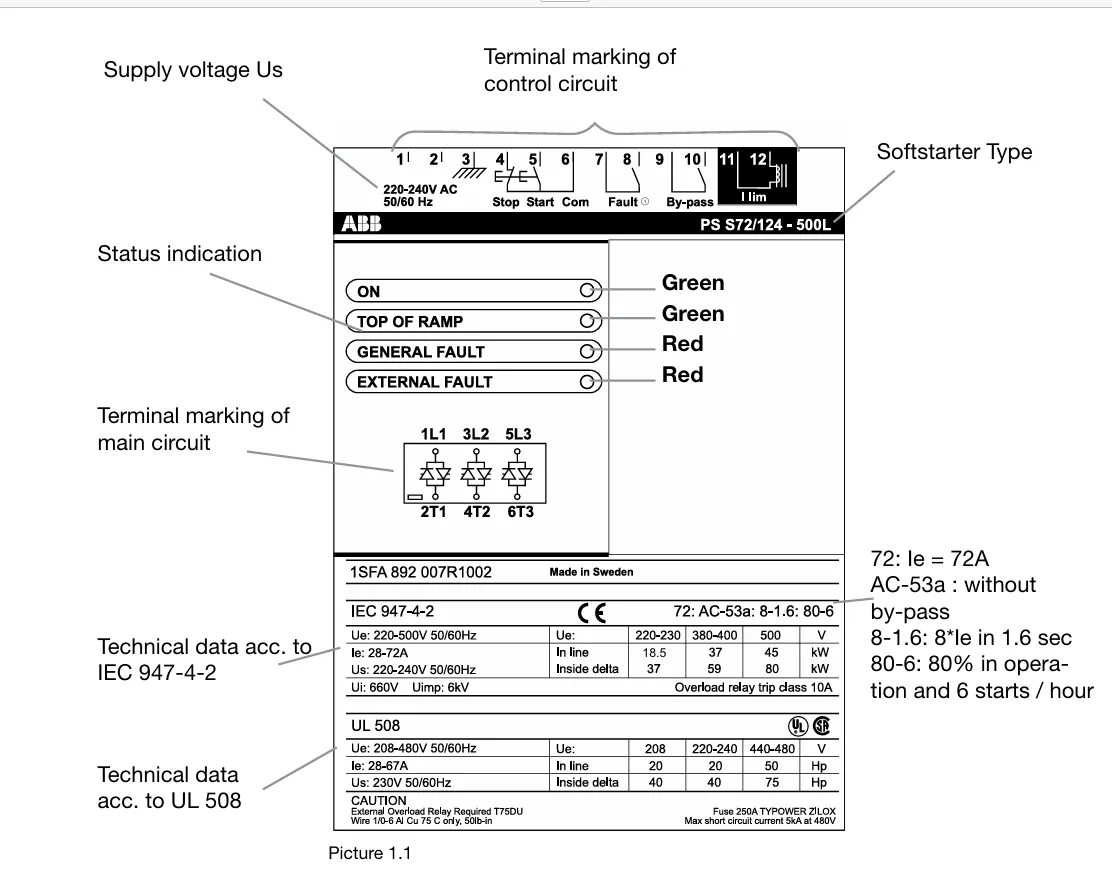

Soft Starter Indications and Their Meanings

Most soft starters include a series of LED lights, status indicators, or display screens to show the current status of the motor, internal system conditions, and faults. These indications vary by brand and model, but several are commonly used in industrial applications.

1. Power ON

This indicator confirms that the soft starter is receiving power and is ready for operation. It usually turns on when the supply voltage is correctly applied to the control circuit.

2. Top of Ramp

This means the start ramp is complete and the motor has received full voltage. If a bypass contactor is used, it will typically close at this stage to reduce heating and improve efficiency.

3. Motor Running

This LED or display confirms that the motor is currently running and the soft starter is actively managing or has handed off to the bypass mode.

4. Fault

A general fault indicator lights up when there is a problem such as:

- Phase failure on the supply side

- Open phase or motor not connected

- Internal fault in the soft starter control or thyristor module

- Incorrect wiring or hardware failure

5. Overload Trip

This light or message appears when the motor current exceeds the overload threshold for too long. Possible causes include:

- Overloaded motor

- Too many start cycles in a short time

- Incorrect overload setting or trip class

- Prolonged start time due to high load

6. Overtemperature

Indicates that the soft starter has become too hot. Causes can include:

- Frequent starting without enough cooling time

- High ambient temperature

- Blocked or non-functioning fans

- Heat sink inefficiency

7. Bypass Active

When lit, this means the bypass contactor is closed and the motor is receiving full voltage directly from the line, bypassing the soft starter. This helps reduce heat and extend soft starter life.

8. Starting / Soft Start In Progress

Indicates the motor is in the starting phase and the voltage is gradually ramping up. This helps reduce inrush current and mechanical stress.

9. Communication Status

Used in models with communication protocols (e.g. Modbus, Profibus). Indicates if the soft starter is connected properly to the PLC or SCADA system. Blinking or solid lights may represent active communication or connection errors.

10. Alarm

Unlike a fault (which causes shutdown), an alarm indicates a non-critical warning such as:

- Motor near overload

- Temperature rising

- Voltage dips or imbalances

11. Stop or Motor Stopped

This confirms the motor is not running and no voltage is being applied. It may blink during coast-to-stop or soft stop processes.

Understanding these indications helps operators and maintenance teams monitor soft starter performance, quickly detect problems, and ensure safe motor operation. Always refer to the specific user manual for detailed LED meanings and fault codes.

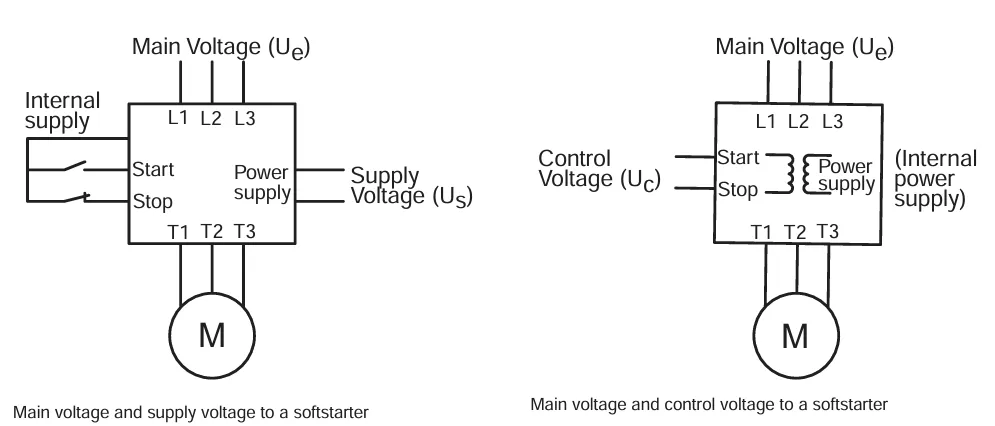

Different Voltages Used in Soft Starters

Soft starters operate using two different types of voltages, each serving a specific function. Understanding the difference between these voltages is important for proper installation, configuration, and troubleshooting. These voltage definitions are standardized under IEC guidelines.

1. Main Voltage (Ue)

This is the voltage supplied directly to the motor through the soft starter’s power circuit. It also passes through the main power components, such as thyristors or SCRs. The main voltage is responsible for driving the motor and is typically in the range of 200 V to 690 V AC, depending on the motor and regional supply standards.

For example, a 3-phase induction motor rated at 415 V will receive this voltage through the soft starter’s power terminals. The soft starter gradually applies this voltage during start-up to limit the inrush current.

2. Supply Voltage (Us)

The supply voltage, sometimes referred to as the control voltage, is used to power the internal electronics of the soft starter. This includes the control circuit, display panel, microcontroller, and communication modules.

Common values for control supply voltage are 110 – 120 V or 220 – 240 V, depending on the design and manufacturer. This voltage is separate from the motor power voltage and must be applied correctly for the soft starter to function.

Correct wiring of both main and control voltages is essential for safe and reliable soft starter operation. Always follow the wiring diagram provided in the manufacturer’s manual and ensure proper voltage ratings before powering the device.

Applications of Soft Starters

Soft starters are widely used in industrial and commercial environments where smooth starting and stopping of electric motors is essential. By gradually increasing the voltage to the motor, soft starters help reduce inrush current, minimize mechanical stress, and extend equipment life. Below are the major application areas of soft starters:

1. Pumping Systems

- Water supply pumps

- Irrigation and agricultural pumps

- Wastewater treatment and sewage pumps

- Booster and circulation pumps

Soft starters prevent water hammer and pressure surges during start/stop cycles, ensuring smooth operation and reducing pipeline damage.

2. HVAC Systems (Heating, Ventilation, Air Conditioning)

- Chillers and compressors

- Cooling tower fans

- Air handling units (AHUs)

They help in reducing stress on motors and compressors during startup, improving energy efficiency and reducing wear and tear.

3. Conveyor Systems

- Assembly line conveyors

- Packaging lines

- Mining and material handling systems

Soft starters provide smooth acceleration and deceleration to avoid product spillage and mechanical shock to gearboxes or belts.

4. Fans and Blowers

- Industrial exhaust fans

- Large ventilation fans

- Cooling fans in power plants

Soft starting reduces high torque and vibration, which can damage fan blades and bearings over time.

5. Compressors

- Air compressors

- Refrigeration compressors

Controlled acceleration helps avoid sudden load impact, reducing mechanical and electrical stress.

6. Crushers, Mixers, and Agitators

- Stone crushers in mining and cement industries

- Industrial mixers and agitators in food and chemical industries

Soft starters prevent abrupt movement and mechanical shocks during starting, which can damage drive systems and reduce productivity.

7. Elevators and Escalators

Smooth starting ensures passenger comfort and reduces wear on motors and gear systems.

8. Textile and Printing Machines

Soft starting avoids sudden tension or misalignment in delicate machinery, reducing the chance of faults.

9. Oil & Gas and Petrochemical Plants

Used for heavy-duty pumps and compressors, soft starters improve operational safety, reduce motor downtime, and support hazardous environment compliance.

10. Renewable Energy and Utilities

Soft starters are used in solar pump systems, wind turbine auxiliaries, and other renewable systems to reduce initial surge and improve system lifespan.

By enabling controlled motor startup and shutdown, soft starters are ideal for a wide range of applications where energy efficiency, equipment protection, and smooth mechanical operation are priorities.