Data Types in Schneider PLC EcoStruxure Control Expert

Published on Aug 28, 2025 | Category: Data typeShare this Page:

Data types in Schneider PLC EcoStruxure Control Expert represent the kind of data that can be storedin memory. For example, a variable like Sensor1 = 11.23 represents a REAL value. Choosing the correct data type ensures that the PLC stores and processes data accurately, which is essential for reliable automation.

Using proper data types is important for programming because it helps manage the PLC’s internal memory efficiently. Each data type occupies a specific amount of memory, and selecting the wrong type can lead to wasted memory or incorrect calculations. This is especially critical in large or complex projects where memory resources are limited.

In PLC programming, understanding and applying the correct data types plays a vital role in program optimization and stability. Standard data types like BOOL, INT, DINT, REAL, and STRING allow programmers to design efficient programs while ensuring that the PLC operates reliably under all conditions. in this article we learn standard data type of Schneider PLC EcoStruxure Control Expert.

What is Data Types in PLC Programming?

Data types in PLC programming specify the kind of data a variable can hold, such as numbers, text, or true/false values. They determine how the PLC stores and processes information in its memory. For instance, a sensor reading like 11.23 would use a REAL data type, while a simple ON/OFF signal would use BOOL. Choosing the correct data type is essential for accurate calculations, efficient memory usage, and reliable program operation.

Importance of Data Types in PLC Programming

- Efficient Memory Usage: Using the correct data type ensures that the PLC memory is used efficiently, which is critical in large or complex programs.

- Accurate Calculations: Data types help the PLC interpret values correctly, preventing errors in arithmetic or logical operations.

- Reliable Program Operation: Correct data types reduce the risk of unexpected behavior and improve the stability of the PLC program.

- Faster Processing: Properly defined data types allow the PLC to process information more quickly, enhancing overall system performance.

- Easy Maintenance: Using consistent and correct data types makes programs easier to read, debug, and maintain over time.

BOOL Data Type in Schneider PLC EcoStruxure Control Expert

The BOOL data type can only have two states: TRUE or FALSE. It is commonly used for binary devices such as switches, coils, ON/OFF sensors, and limit switches.

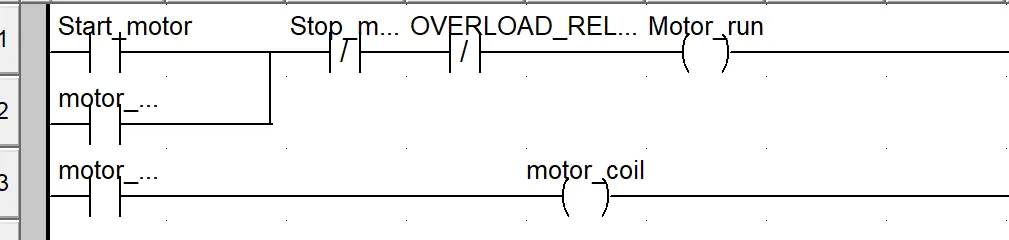

in this example a simple motor on off with momentry push button

These examples demonstrate how BOOL variables are ideal for simple ON/OFF control in ladder diagrams, providing clear and reliable logic for various industrial applications.

- If Start_Button is pressed (TRUE), the Motor coil will energize (turn ON).

- If Stop_Button is pressed (TRUE), the Motor coil will de-energize (turn OFF).

- A BOOL input from an overload relay (Overload_Trip) monitors motor health.

- If Overload_Trip is TRUE, the Motor coil is immediately de-energized to protect the motor.

EBOOL Data Type in Schneider PLC EcoStruxure Control Expert

The EBOOL (Enhanced BOOL) is similar to the regular BOOL data type in that it can only hold TRUE (=1) or FALSE (=0) values. However, EBOOL is “enhanced” because it also carries additional information about signal changes, such as rising edges (transition from FALSE to TRUE) and falling edges (transition from TRUE to FALSE), and it supports forcing (temporarily overriding the value for testing or maintenance).

Key Rules:

- EBOOL variables cannot replace standard BOOL variables in input/output parameters.

- EBOOL arrays cannot be assigned to BOOL arrays or passed as general ANY-type parameters in function blocks.

- On Quantum PLCs, EBOOL variables and arrays have restrictions in function blocks (cannot be passed as input/output or DFB parameters).

In short, EBOOL is ideal for situations where you need more control over binary signals, like detecting edges or forcing values, while maintaining TRUE/FALSE logic.

Numerical Data Types in Schneider PLC

Numerical data types in Schneider PLCs are used to store integer and decimal values in different memory sizes. They can be signed or unsigned, and each type has a specific range depending on its bit format.

- INT (Integer): A signed 16-bit integer type. It can store values from -32,768 to 32,767 in decimal format. Suitable for small-range whole numbers.

- DINT (Double Integer): A signed 32-bit integer type. It can store values from -2,147,483,648 to 2,147,483,647. Ideal for larger whole numbers in calculations or counters.

- UINT (Unsigned Integer): A 16-bit unsigned integer type. It stores only positive numbers, ranging from 0 to 65,535. Useful when negative values are not required.

- UDINT (Unsigned Double Integer): A 32-bit unsigned integer type. It can store values from 0 to 4,294,967,295. Used for large positive numbers in applications like timers, counters, or high-precision measurements.

Choosing the correct numerical type ensures efficient memory usage and accurate calculations in PLC programs. Smaller types like INT or UINT save memory, while larger types like DINT or UDINT handle bigger ranges when required.

REAL Data Type in Schneider PLC EcoStruxure Control Expert

The REAL data type is used to store floating-point numbers, which include decimal values. It is typically a 32-bit format and allows representation of both positive and negative numbers with fractional parts. REAL is essential when precise measurements or calculations are needed, such as temperature, pressure, or speed.

Using REAL ensures that your PLC program can handle measurements and computations accurately. Unlike integer types, which store whole numbers, REAL allows fine precision, which is crucial in process control and measurement-based applications.

STRING Data Type in Schneider PLC EcoStruxure Control Expert

The STRING data type is used to store a sequence of ASCII characters, ideal for storing names, messages, or textual information in a PLC program. Each character uses 8 bits, and by default, a STRING can hold 16 characters, though it can be extended up to 65,535 using STRING[size]. Empty strings start with a special end-of-string character to indicate no content.

STRING also supports special characters for formatting: $L (line feed), $N (new line), $R (carriage return), $T (tab), $$ (dollar sign), and $’ (quote character). These allow creating readable messages or complex text outputs in your PLC program.

Practical Examples:

- STRING: 'PumpON' → Stores the text "PumpON" followed by end-of-string characters.

- STRING[6]: 'Alarm' → Stores "Alarm" with one extra empty character.

- STRING[12]: 'Door$NOpen' → Stores "Door" then moves to a new line for "Open".

- STRING[8]: '$$Status' → Displays "$Status" in the PLC output.

STRING variables can be declared as STRING or STRING[size] depending on how many characters you need to store. Using STRING effectively allows clear, readable text handling in your automation project.

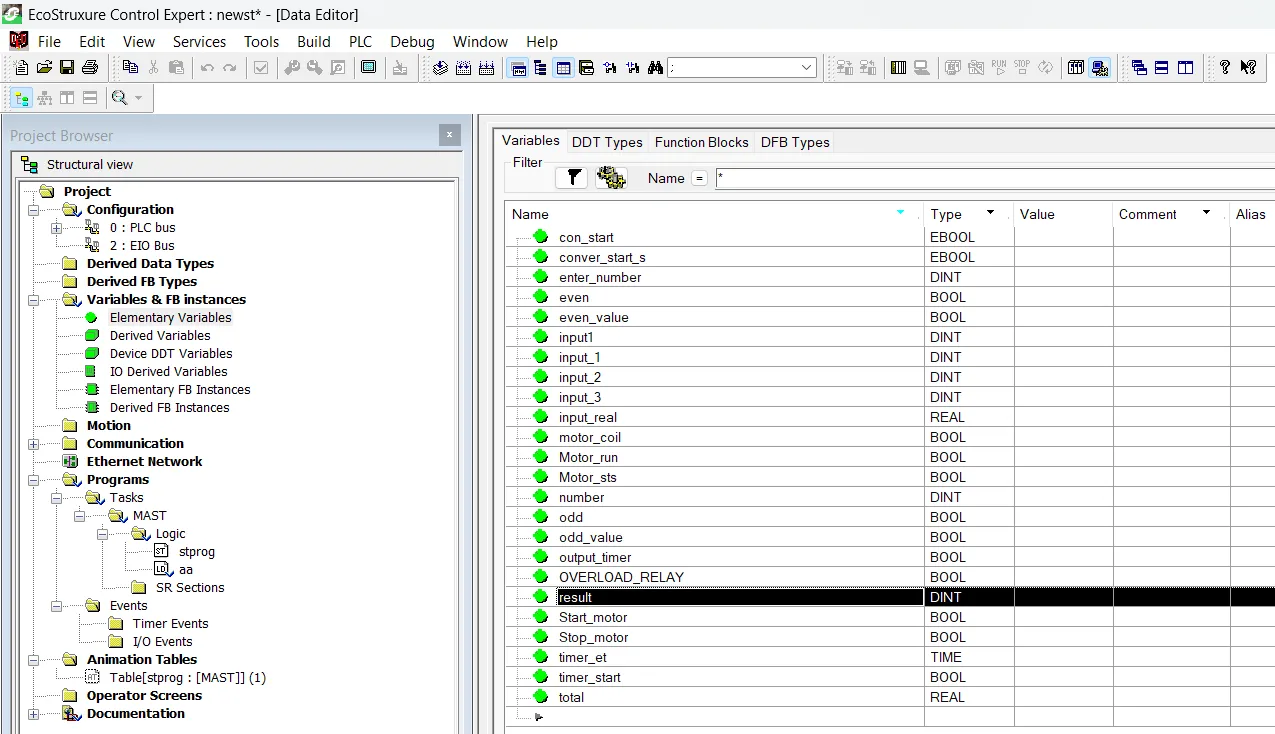

How to Assign Data Types in EcoStruxure Control Expert

In EcoStruxure Control Expert, you can assign data types to variables in two main ways:

- Using the Variable Table: Open the project tree, select a variable or a function block (FB) instance, and then choose an elementary variable. The variable table will open, where you can declare new variables and assign the appropriate data types from the dropdown list. This method is ideal for organizing all variables in one place and managing large programs efficiently.

- Directly in Instructions: You can also enter a variable directly in a program instruction and select its data type on the spot. This method is faster for quick variable creation and immediate use within a specific instruction.

Both methods ensure that the PLC knows how to store and process each variable correctly, making your program reliable and memory-efficient.

Best Practices for Using Data Types in PLC Programs

Choosing the correct data type in PLC programming is essential for reliable, efficient, and maintainable programs. Here are some best practices to follow:

- Select the smallest appropriate data type: Use smaller data types like BOOL or INT when possible to save PLC memory.

- Use signed and unsigned types carefully: Ensure that negative values are allowed only when necessary. For example, use INT for temperatures but UINT for counters that cannot be negative.

- Be consistent: Use the same data type for related variables to avoid conversion errors and simplify program logic.

- Use REAL or LREAL for precise calculations: For analog values, measurements, or calculations with decimals, always use floating-point types.

- Declare string sizes thoughtfully: When using STRING variables, define the maximum required size to save memory and prevent overflow.

- Document variable usage: Always comment the purpose of each variable and its type, especially for complex programs or large teams.

- Test edge cases: Ensure variables can handle maximum and minimum values, especially for counters, timers, and sensor readings.

Following these best practices ensures that your PLC programs are efficient, easy to maintain, and less prone to errors, while making optimal use of PLC memory.