Introduction to Schneider EcoStruxure Control Expert

Published on Sep 05, 2025 | Category: IntroductionShare this Page:

Schneider EcoStruxure Control Expert is a software used to program and configure Schneider PLCs. Formerly known as Unity Pro, it provides an intuitive environment for designing, testing, and deploying automation projects efficiently.

Whether you are working on small machines or large industrial systems, Control Expert helps you manage your PLC programs with ease. It offers advanced tools for debugging, simulation, and monitoring, making automation tasks faster and more accurate. With its modern interface and robust features, Control Expert enhances productivity for engineers and technicians alike. It simplifies complex automation processes and ensures reliable performance in industrial applications.

What is Schneider EcoStruxure Control Expert?

Schneider EcoStruxure Control Expert is a modern PLC programming software and the successor to Unity Pro. It allows engineers and technicians to program, configure, and manage Schneider PLCs efficiently. The software offers tools for designing, debugging, simulating, and monitoring automation projects, whether small machines or large industrial systems. With its user-friendly interface and robust features, Control Expert simplifies complex automation processes, reduces errors, and ensures reliable performance in industrial applications.

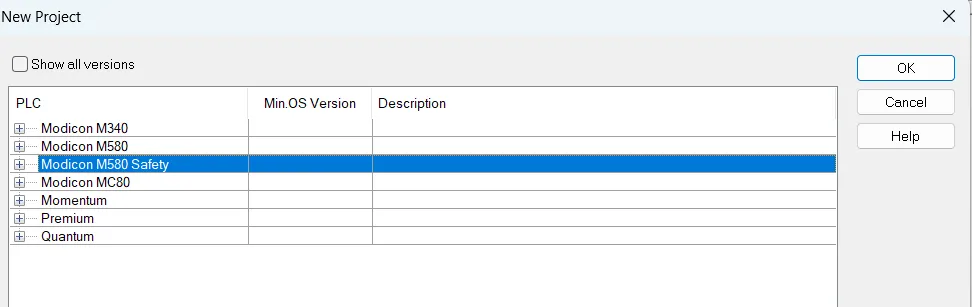

PLC and Devices Supported by Schneider EcoStruxure Control Expert

Schneider EcoStruxure Control Expert supports a wide range of Schneider PLCs and automation devices, making it a versatile tool for configuring, programming, and managing industrial systems. Engineers can use Control Expert to program PLCs, configure inputs and outputs, and integrate devices from the following hardware platforms:

- Modicon M340: A mid-range PLC suitable for small to medium automation projects, supporting digital and analog I/O configuration.

- Modicon M580: A high-performance Ethernet-enabled PLC for large-scale industrial automation, offering advanced control and networking capabilities.

- Quantum: A robust PLC platform for critical industrial processes, capable of handling complex control systems and multiple I/O modules.

- Momentum: Compact PLCs ideal for machine-level automation, providing flexible input/output management and cost-effective solutions.

- Premium: Versatile PLCs for various industrial applications, supporting distributed I/O and multiple communication protocols.

- Atrium: PLCs designed for process automation, offering seamless integration with other Schneider devices and efficient control configuration.

With Control Expert, users can configure these PLCs, set up digital and analog inputs and outputs, monitor real-time data, and manage communication with connected devices, ensuring smooth and reliable automation across industrial systems.

Programming Languages in Schneider EcoStruxure Control Expert

Schneider EcoStruxure Control Expert supports multiple programming languages for creating PLC user programs, allowing engineers to choose the best method for their automation needs. All languages (except LL984) conform to the international standard IEC 61131-3, which ensures portability and standardization across different PLC platforms. The supported languages include:

- Function Block Diagram (FBD): A graphical programming language where functions are represented as blocks, making it easy to visualize control logic and data flow between functions.

- Ladder Diagram (LD): A graphical language resembling electrical relay logic, widely used for discrete control applications like switches, relays, and outputs.

- Instruction List (IL): A low-level textual language similar to assembly, providing detailed step-by-step control for precise operations.

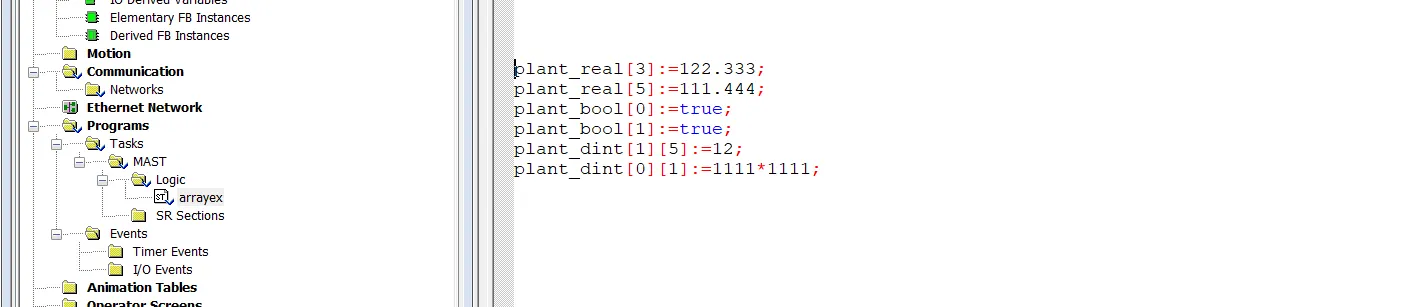

- Structured Text (ST): A high-level textual language similar to programming languages like Pascal, allowing complex calculations, loops, and conditional statements.

- Sequential Function Chart (SFC): A graphical language used to design sequential processes, representing steps, transitions, and actions clearly in a flowchart-like structure.

- Ladder Logic 984 (LL984): A legacy ladder logic language specific to older Schneider systems, included for backward compatibility.

All these programming languages can be combined within the same project, giving flexibility to use the most appropriate language for each part of the automation system.

Elements of a Program in Schneider EcoStruxure Control Expert

A program in Schneider EcoStruxure Control Expert is structured using various tasks and program units to manage automation efficiently. The main elements of a program include:

- Master Task (MAST): The primary task that controls the execution of the program and coordinates other tasks.

- FAST Task: A high-priority task for rapid execution, not available for Momentum PLCs.

- AUX Tasks: Auxiliary tasks that allow parallel processing, with one to four tasks available (not available for Modicon M340 and Momentum).

- Program Units: Modular blocks assigned to defined tasks, available for Modicon M580 and Modicon M340, used to organize and manage the program logic efficiently.

- Sections: Logical divisions within a program assigned to defined tasks for better organization of control logic.

- Timerx Sections: Sections designed to handle time-controlled events, not available for Momentum PLCs.

- EVTx Sections: Sections for processing hardware-controlled events, also not available for Momentum PLCs.

- Subroutine Sections (SR): Reusable sections of code that can be called from different parts of the program to simplify programming and reduce redundancy.

These elements allow engineers to structure complex automation programs efficiently, manage execution priority, and handle both time-based and hardware-based events within Schneider PLC systems.

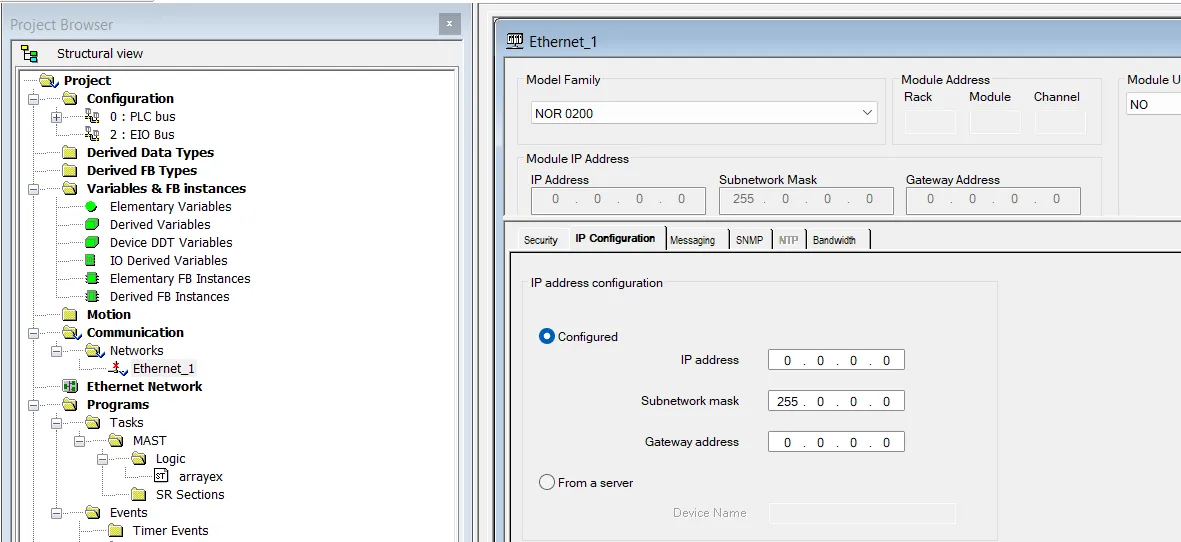

Communication Protocols Supported by Schneider EcoStruxure Control Expert

Schneider EcoStruxure Control Expert supports several key communication protocols to ensure reliable connectivity and seamless integration with PLCs, devices, and industrial networks. The software supports Modbus (RTU & TCP/IP) for serial and Ethernet communication, Ethernet/IP for industrial Ethernet connections with controllers, drives, and HMIs, and standard Serial Communication (RS232/RS485) for connecting legacy devices and I/O modules. These protocols enable efficient data exchange between PLCs, HMI/SCADA systems, drives, and other automation equipment, ensuring real-time and reliable control.

By supporting these communication protocols, Control Expert ensures flexible connectivity, interoperability with multiple devices, and efficient management of industrial automation systems.

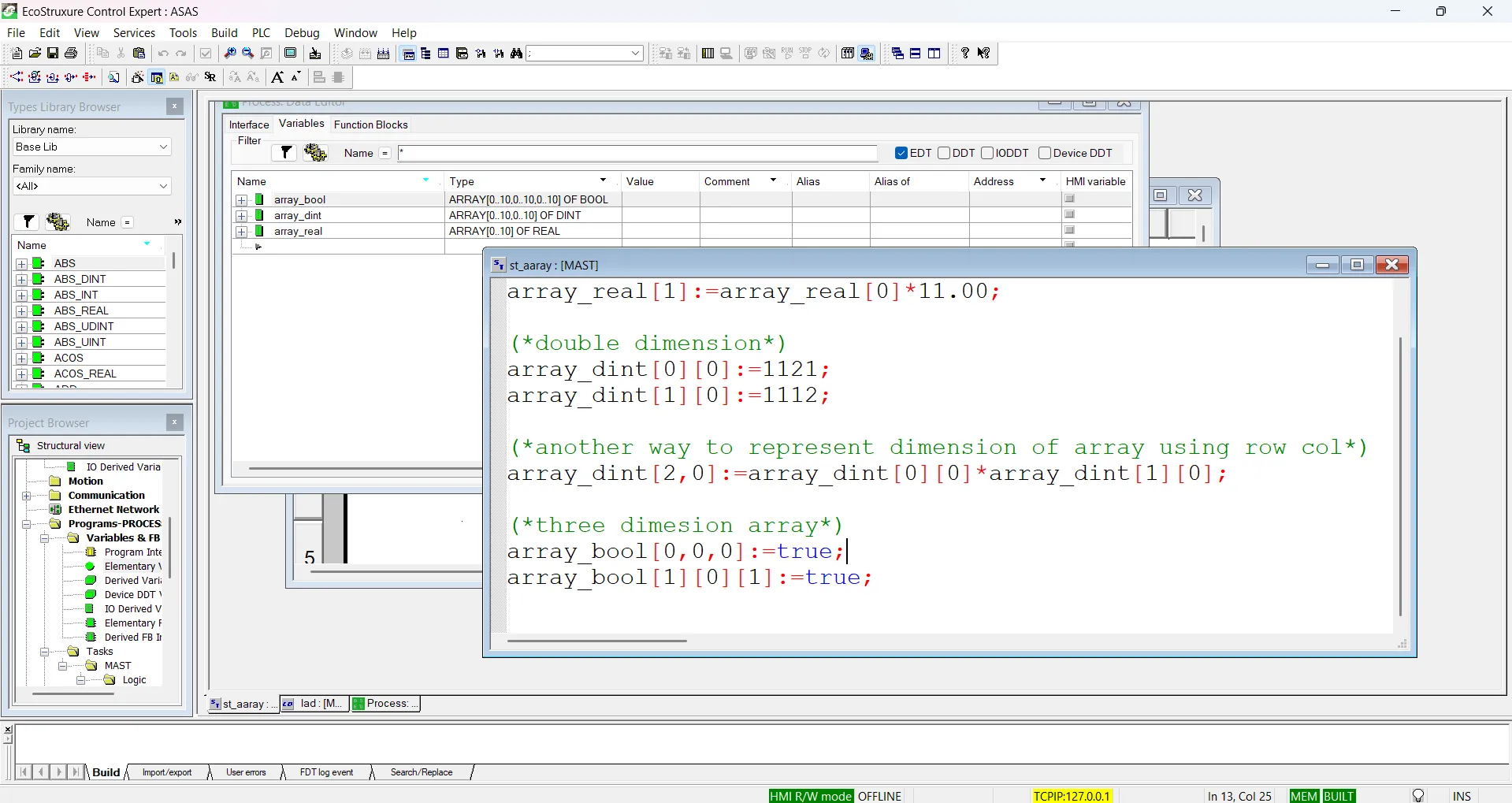

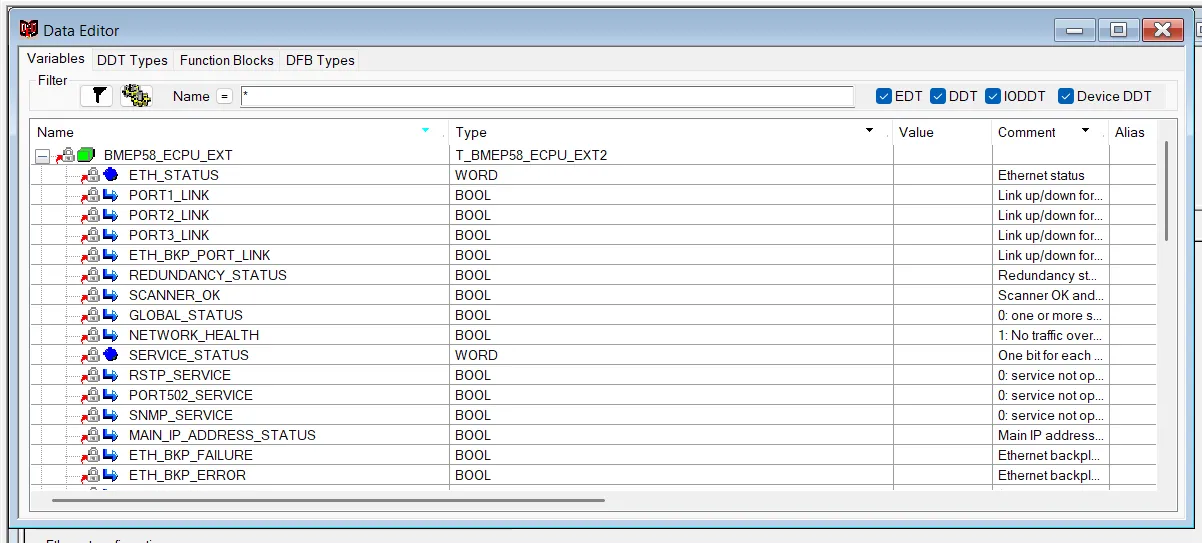

Variables in Schneider EcoStruxure Control Expert

In Schneider EcoStruxure Control Expert, variables are used to store and manage data within a PLC program. They represent values such as inputs, outputs, timers, counters, or internal memory locations and are essential for program logic, calculations, and control operations. Variables can be created, configured, and monitored to manage the flow of information in automation projects.

Variables in Control Expert belong to different families, each serving a specific purpose:

- Elementary Data Types (EDT): Basic types such as BOOL, INT, REAL, and STRING used to store simple values.

- Derived Data Types (DDT): Custom data types created by combining multiple elementary types into structured formats for more complex data management.

- Derived Data Types referencing I/O (Input/Output Data Types): Special DDTs linked to physical PLC inputs and outputs, allowing structured access to hardware signals.

- Device Derived Data Types (Device DDT): Data types provided by specific devices or modules, enabling easy integration and configuration of external hardware within the program.

By organizing variables into these families, Control Expert allows users to efficiently manage data, improve program readability, and ensure seamless interaction between the PLC program and connected devices.

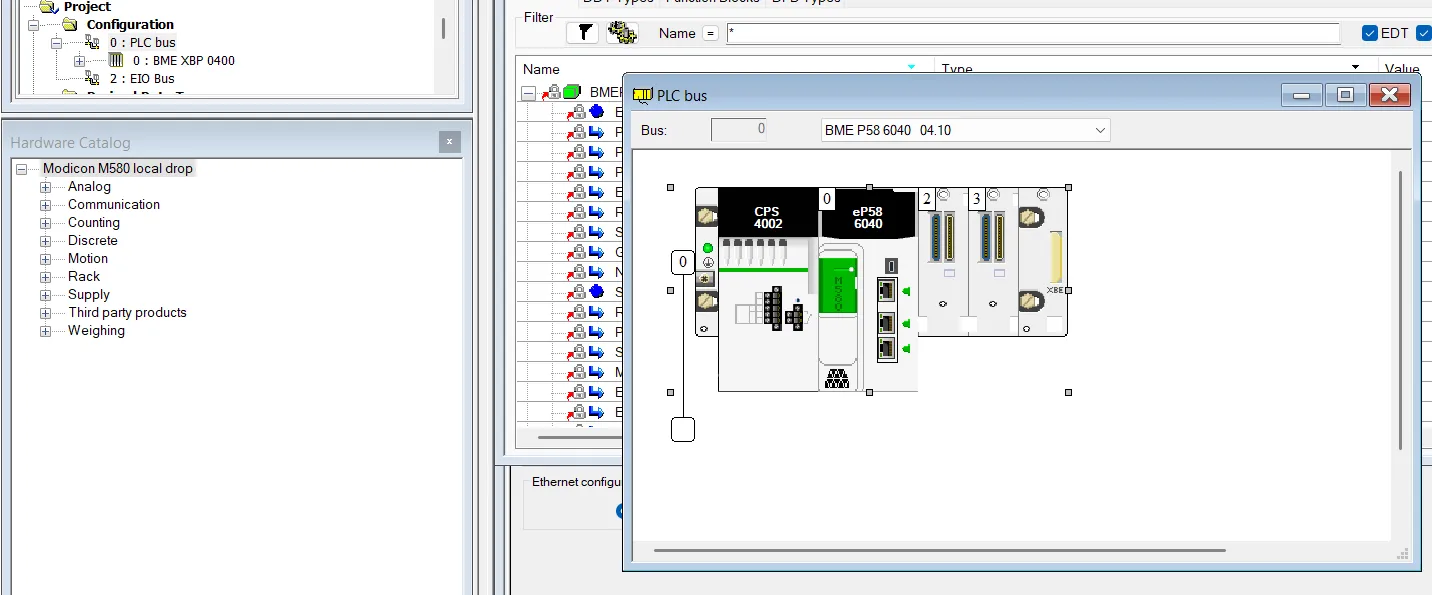

Schneider PLC Hardware Configuration

In Schneider EcoStruxure Control Expert, the Hardware Configuration feature allows engineers to easily set up and manage PLC hardware. You can add and configure various input and output modules—including analog, discrete, communication, motion, power supply modules, and even third-party weighing modules—according to your automation system requirements. The visual interface lets you arrange PLC racks, assign slots, configure module addresses, and define connections for each module, ensuring accurate mapping of all I/O points.

Commonly used modules include:

- Analog Modules: Measure or control analog signals such as voltage, current, temperature, or process variables.

- Discrete Modules: Handle digital inputs and outputs like switches, relays, and binary actuators.

- Communication Modules: Enable networking with protocols such as Modbus, Ethernet/IP, PROFINET, or CANopen.

- Motion Rack Modules: Control motors, drives, and motion systems in precise automation applications.

- Power Supply Modules: Provide reliable power to racks and modules, ensuring stable operation.

- Third-Party Weighing Modules: Integrate external weighing or measurement devices seamlessly into the PLC system.

By configuring these modules in Control Expert, users can design a robust and flexible PLC hardware system that integrates both Schneider and compatible third-party devices, enabling smooth operation of industrial automation processes.

Simulation Features in Schneider EcoStruxure Control Expert

Schneider EcoStruxure Control Expert provides powerful simulation features that allow engineers to test and validate PLC programs before deploying them to physical hardware. Using the simulation environment, users can execute programs, monitor variable values, and test logic without connecting to the actual PLC. This helps identify errors, optimize control sequences, and verify program functionality safely and efficiently.

Key simulation features include:

- Offline Simulation: Run and test programs entirely on a computer without requiring the PLC hardware.

- Online Monitoring: Observe real-time data and variable states when connected to a PLC, enabling debugging and analysis.

- Breakpoint and Step Execution: Pause program execution at specific points to analyze logic flow and variable changes step by step.

- Force and Override Variables: Test specific conditions by temporarily forcing variable values, simulating real-world scenarios.

- Watch and Trend Variables: Monitor variable values over time using watch windows and trend charts. The following table summarizes their features:

How to Download Schneider EcoStruxure Control Expert

Schneider EcoStruxure Control Expert can be downloaded directly from the official Schneider Electric website. The software offers a 30-day free trial, allowing users to explore its features before purchasing a full license. To download, you need to create a Schneider account, select the appropriate software version, and follow the on-screen instructions for installation. After the trial period, a valid license is required to continue using the software for professional projects.