Complete Guide to Timers in EcoStruxure Control Expert (Schneider PLC)

Published on Aug 21, 2025 | Category: timerShare this Page:

A timer in a PLC is a crucial programming tool used to create time-based control sequences. In EcoStruxure Control Expert, Schneider PLCs support various timer types including TON (On-Delay Timer), TP (Pulse Timer), and TOF (Off-Delay Timer). Each timer type serves a specific function: TON delays turning on an output, TP generates a fixed pulse, and TOF delays turning off an output. These timers are fundamental for managing sequences, delays, and events within automated processes.

Timers in Schneider PLCs are widely used in industrial automation to control machinery, manage process sequences, and optimize operations. Practical applications include conveyor control, motor sequencing, process timing, and retentive operations. By using timers effectively, engineers can ensure precise timing, reliable automation, and enhanced efficiency in manufacturing systems. Learning how to implement PLC timer programming examples in ladder logic or Structured Text provides hands-on experience for real-world industrial applications

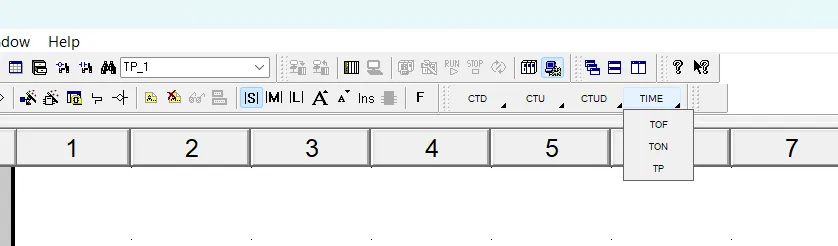

Types of IEC Timers in EcoStruxure Control Expert (Schneider PLC)

IEC timers in Schneider PLCs are standard timer instructions used to control time-based operations in automation processes. These timers help manage delays, pulses, and retentive functions efficiently.

- TON (On-Delay Timer)

- TOF (Off-Delay Timer)

- TP (Pulse Timer)

TIME Data Type in EcoStruxure Control Expert (Schneider PLC)

The TIME data type is used to represent a duration or interval in milliseconds. It is stored in 32 bits, which allows it to represent durations from 0 up to 4,294,967,295 milliseconds (roughly 49.7 days). The TIME type can include different units such as days (d), hours (h), minutes (m), seconds (s), and milliseconds (ms).

A literal TIME value is written using prefixes like T#, t#, TIME#, or time#, followed by the duration in a combination of units. For example, you might specify a timer interval as T#2h30m for 2 hours and 30 minutes, t#10s500ms for 10.5 seconds, or TIME#1d4h15m20s250ms for 1 day, 4 hours, 15 minutes, 20 seconds, and 250 milliseconds.

These TIME literals are very useful when configuring timers like TON, TOF, or TP, or when performing calculations that involve durations in your PLC programs.

Authorized Units for TIME

When specifying a TIME value, you can use the following units: Days (D), Hours (H), Minutes (M), Seconds (S), and Milliseconds (MS). These units can be combined to represent complex durations.

Entering TIME Values

You can enter TIME values in several ways, all representing the same maximum duration of 4,294,967,295 milliseconds:

Examples of TIME Values

Here are some different ways to represent durations using the TIME type:

- T#5000000MS – Duration expressed entirely in milliseconds (5 million milliseconds ≈ 1 hour 23 minutes).

- T#7200S_500MS – Duration in seconds and milliseconds (7200 seconds and 500 milliseconds ≈ 2 hours 0.5 seconds).

- T#120M_30S_250MS – Duration in minutes, seconds, and milliseconds (120 minutes, 30 seconds, 250 milliseconds ≈ 2 hours 0.5 minutes).

- T#48H_15M_10S_100MS – Duration in hours, minutes, seconds, and milliseconds (48 hours, 15 minutes, 10 seconds, 100 milliseconds ≈ 2 days 0.6 hours).

- T#3D_6H_45M_30S_500MS – Duration in days, hours, minutes, seconds, and milliseconds (3 days, 6 hours, 45 minutes, 30.5 seconds).

Using these TIME literals allows precise control over PLC timers and ensures predictable timing for automation tasks.

Parameters of Timers in EcoStruxure Control Expert (Schneider PLC)

Timers in Schneider PLCs, such as TON, TOF, and TP, have common parameters that control their behavior. Understanding these parameters is essential for accurate timing and automation sequences.

1. IN (Input)

The IN parameter is the logic input that starts or triggers the timer. For TON and TP, the timer starts counting when IN becomes TRUE. For TOF, the timer starts its off-delay countdown when IN becomes FALSE.

2. PT (Preset Time)

The PT parameter defines the duration for which the timer should count. It is a TIME type value (e.g., T#5S for 5 seconds, T#2M_30S for 2 minutes 30 seconds). This determines when the output will activate or deactivate depending on the timer type.

3. Q (Output)

The Q parameter is the timer output. For TON, it becomes TRUE after the preset time elapses. For TOF, it remains TRUE during the off-delay period. For TP, it generates a pulse of the preset duration.

4. ET (Elapsed Time)

The ET parameter shows the elapsed time since the timer started counting. This is useful for monitoring progress and debugging timing sequences.

5. Additional Notes

- All timers use the TIME data type for the preset duration (PT).

- The timers can be used in both Ladder Logic and Structured Text programming.

- Accurate parameter configuration ensures precise automation control and prevents unexpected behavior.

By correctly setting IN, PT, Q, and ET, engineers can implement reliable timers in industrial automation using EcoStruxure Control Expert.

TON (On-Delay) Timer in Schneider PLC – EcoStruxure Control Expert

The TON timer, or On-Delay Timer, delays turning on an output after its input condition becomes TRUE. It is commonly used when a controlled delay is needed before activating machinery, motors, or signals. The timer starts counting as soon as the input is activated, and the output turns ON only after the preset time (PT) has elapsed.

Parameters of TON Timer

- IN: Input signal to start the timer (e.g., a Start Button).

- PT: Preset time (duration for the delay, e.g., T#5S for 5 seconds).

- Q: Output that turns ON after the timer elapses.

- ET: Elapsed time since the timer started.

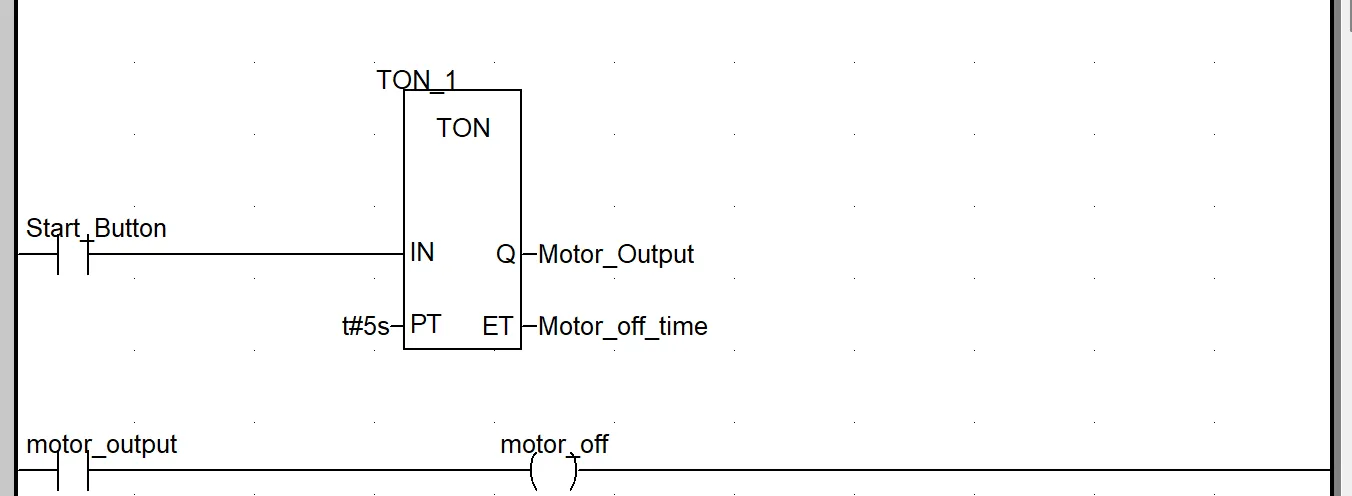

Example in Ladder Logic

Suppose you want a motor to start 5 seconds after pressing a start button:

Explanation:

- When the Start_Button is pressed (IN = TRUE), the TON timer starts counting.

- The timer waits for the preset time T#5S.

- After 5 seconds, the output Motor_Output turns ON.

- The ET parameter shows the elapsed time during the delay.

This setup ensures the motor starts only after a controlled delay, preventing abrupt starts and providing safe operation in industrial automation.

TOF (Off-Delay) Timer in Schneider PLC – EcoStruxure Control Expert

The TOF timer, or Off-Delay Timer, delays turning off an output after its input condition becomes FALSE. It is useful when you want the output to remain active for a specific duration after the input is deactivated, such as keeping a motor running briefly after a stop button is pressed.

Parameters of TOF Timer

- IN: Input signal controlling the timer (e.g., a Stop Button).

- PT: Preset time (duration for the off-delay, e.g., T#5S for 5 seconds).

- Q: Output that remains TRUE during the off-delay period.

- ET: Elapsed time since the off-delay started.

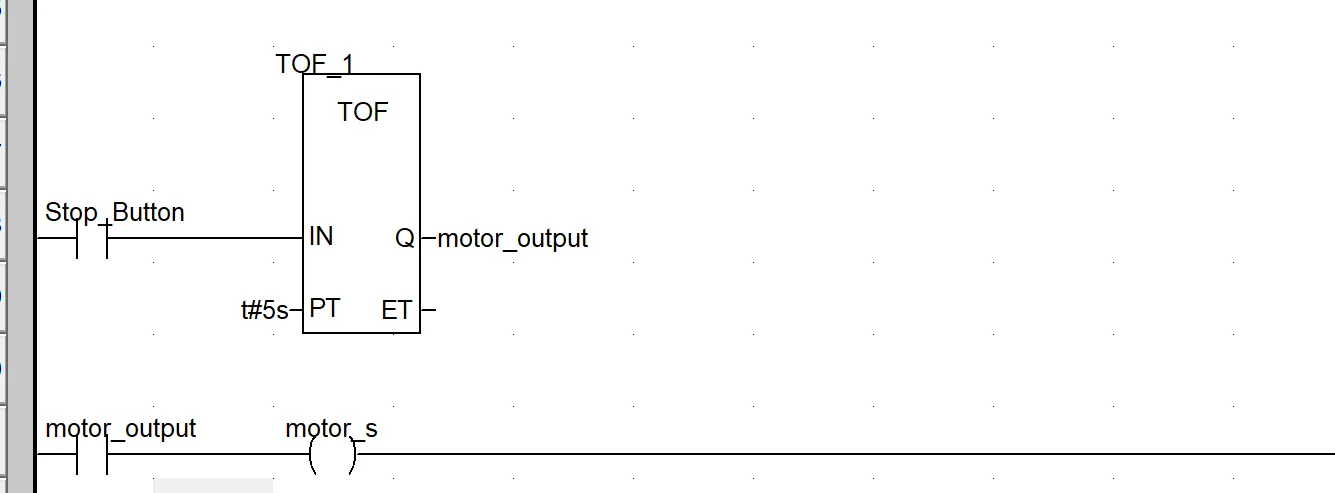

Example in Ladder Logic

Suppose you want a motor to continue running for 5 seconds after pressing the stop button:

Explanation:

- When the Stop_Button is pressed (IN = FALSE), the TOF timer begins its countdown.

- The output Motor_Output remains TRUE for the preset time T#5S before turning OFF.

- The ET parameter tracks the elapsed off-delay time.

This configuration ensures smooth shutdowns and prevents abrupt stopping of machinery, which is essential for safe and reliable industrial automation.

TP (Pulse) Timer in Schneider PLC – EcoStruxure Control Expert

The TP timer, or Pulse Timer, generates a fixed-duration pulse on its output regardless of how long the input signal remains TRUE. It is ideal for short, timed actions where precise pulse control is required, such as triggering a signal lamp, solenoid, or other momentary devices.

Parameters of TP Timer

- IN: Input signal that triggers the pulse.

- PT: Preset time for the pulse duration (e.g., T#2S for 2 seconds).

- Q: Output that becomes TRUE for the pulse duration.

- ET: Elapsed time of the pulse.

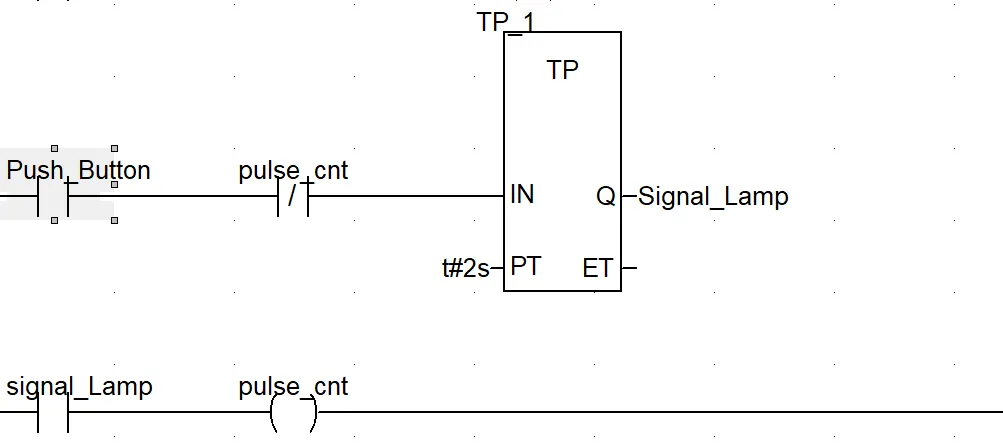

Example in Ladder Logic

Suppose you want to turn on a signal lamp for exactly 2 seconds when a button is pressed:

Explanation:

- When the Push_Button is pressed (IN = TRUE), the TP timer generates a pulse on Signal_Lamp every 2 second..

- The output stays ON for the preset time T#2S regardless of how long the input remains TRUE.

- The ET parameter shows the elapsed pulse duration.

This timer is ideal for precise momentary actions in industrial automation, ensuring reliable and consistent pulse outputs.

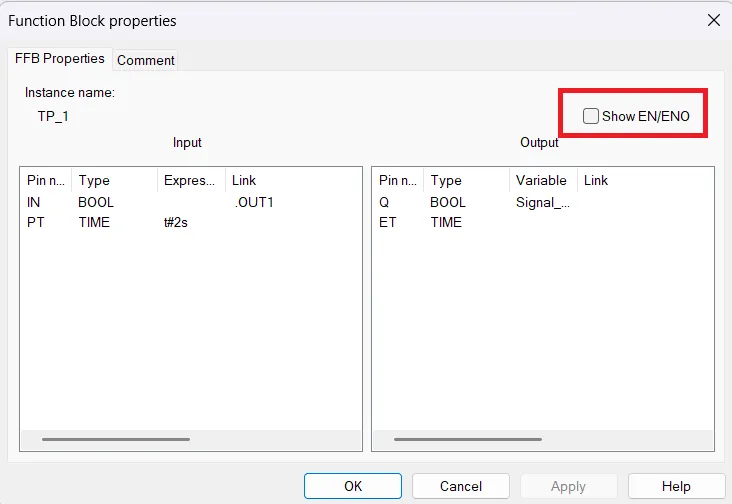

Steps to Enable or Disable EN/ENO

- Double-click on the timer block to open its properties window.

- in function block properties Look for the option labeled EN/ENO in the block settings.

- Uncheck the box to disable EN/ENO, or check it to enable EN/ENO.

- Click OK to save changes and close the properties window.

Disabling EN/ENO is useful when you want the timer to execute unconditionally, without being controlled by an enable input. It can simplify logic in certain automation scenarios.