Schneider PLC Counter Programming in EcoStruxure Control Expert

Published on Aug 27, 2025 | Category: counterShare this Page:

In Schneider PLC programming, counters are used to count events or pulses.

The most common types are CTU (Count Up), CTD (Count Down), and CTUD (Count Up/Down).

The CTU increases the count value each time the input condition is true, while the CTD decreases the count value when triggered.

The CTUD combines both functions, allowing counting in both directions depending on the input signal.

Counters are widely used in automation processes where tracking the number of operations, cycles, or parts is required.

For example, they can be used to count bottles on a conveyor, machine cycles, or operator actions.

Once the preset value is reached, the counter sets an output signal that can be used to trigger further actions in the process.

In EcoStruxure Control Expert, counters are easy to configure in Ladder or Structured Text programming.

They include parameters such as current value (CV), preset value (PV), and reset input for clearing the counter.

This makes them flexible for applications like production monitoring, safety interlocks, or sequence control in industrial automation.

Counters in Schneider PLC (EcoStruxure Control Expert)

In Schneider PLC programming, counters are special instructions used to count events, pulses, or machine operations. They are very useful in automation systems where repetitive tasks or quantities need to be measured and controlled. Counters work with a current value (CV) that changes based on input signals and compare it with a preset value (PV) to trigger an output.

The main types of counters available in EcoStruxure Control Expert are:

- CTU (Count Up): Increases the counter value each time the input condition becomes true. Used to count items like bottles on a conveyor.

- CTD (Count Down): Decreases the counter value with each trigger. Often used when starting from a preset value and counting down to zero.

- CTUD (Count Up/Down): A combination of CTU and CTD, allowing counting in both directions depending on the input signal. Useful for position tracking or reversible operations.

These counters are simple to use in Ladder, FBD, or Structured Text within EcoStruxure Control Expert. They are widely applied in industrial automation for production monitoring, cycle counting, and process control.

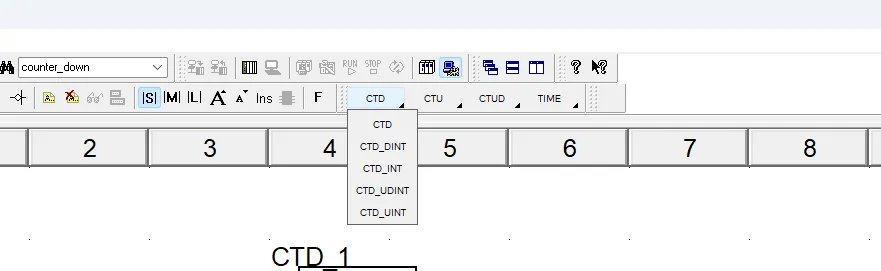

Counters by Data Type in Schneider PLC

In Schneider PLC programming with EcoStruxure Control Expert, counters are available in different data types to handle various counting ranges. This expansion follows the IEC 61131-3 standard, allowing counters to store values as signed or unsigned integers with different bit sizes. The choice of data type ensures that the counter can manage the required number of events without overflow in industrial applications.

- INT: 16-bit signed integer (–32,768 to 32,767). Suitable for medium-range counting tasks.

- DINT: 32-bit signed integer (–2,147,483,648 to 2,147,483,647). Used for large-scale counting with possible negative values.

- UINT: 16-bit unsigned integer (0 to 65,535). Ideal for positive-only counting in smaller ranges.

- UDINT: 32-bit unsigned integer (0 to 4,294,967,295). Best for very large counting applications where only positive values are needed.

All three counter types—CTU (Count Up), CTD (Count Down), and CTUD (Count Up/Down)—are available in these data type variations, making them flexible for use in different automation scenarios such as production tracking, cycle monitoring, and process control.

CTU Counter in Schneider PLC

The CTU (Count Up) counter in Schneider PLC is used to increase a value each time a trigger condition occurs. It starts from zero (or a loaded value) and increments toward the preset value (PV). When the counter reaches the preset value, the output (Q) becomes TRUE. CTU counters are commonly used to count parts, machine cycles, or events in industrial automation.

Input Parameters:

- CU (BOOL): Trigger input that increments the counter each time it transitions from FALSE to TRUE.

- LD (BOOL): Load input that sets the counter to the preset value (PV) when TRUE.

- PV: Preset value.

When CTU: INT

When CTU_***: INT, DINT, UINT, UDINT

Output Parameters:

- Q (BOOL): Output becomes TRUE when the current value (CV) reaches the preset value (PV).

- CV: Current value of the counter.

When CTU: INT

When CTU_***: INT, DINT, UINT, UDINT

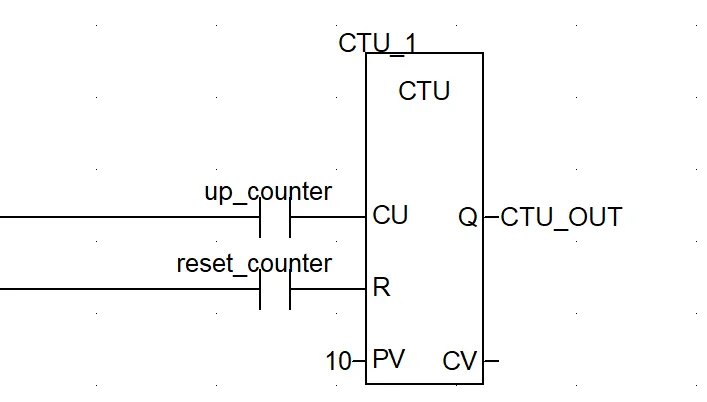

CTU Counter Example with Reset

In this example, the CTU (Count Up) counter counts events up to a preset value (PV). The preset value (PV) is set to 10, meaning the counter output (Q) becomes TRUE when the current value (CV) reaches 10.

The trigger input for counting is CU. Each time CU transitions from FALSE to TRUE, the counter increments its CV by 1.

The Reset input (R or reset_counter) is used to clear the counter when required. For example, if a batch is completed or a process is restarted, activating the reset input sets CV back to 0 and Q becomes FALSE.

This ensures that the counter can start a new counting cycle without retaining the previous count. Such a reset mechanism is commonly used in production lines to count items per batch or per shift.

CTD Counter in Schneider PLC

The CTD (Count Down) counter in Schneider PLC is used to decrease a value each time a trigger condition is met. It starts from a preset value (PV) and counts down toward zero. When the counter reaches zero, the output (Q) becomes true. This function is widely used in applications where operations need to be limited to a certain number of cycles or events.

Input Parameters:

- CD (BOOL): Trigger input that decrements the counter each time it transitions from FALSE to TRUE.

- LD (BOOL): Load input that loads the preset value (PV) into the counter when TRUE.

- PV: Preset value.

When CTD: INT

When CTD_***: INT, DINT, UINT, UDINT

Output Parameters:

- Q (BOOL): Output becomes TRUE when the counter value (CV) reaches zero.

- CV: Current value of the counter.

When CTD: INT

When CTD_***: INT, DINT, UINT, UDINT

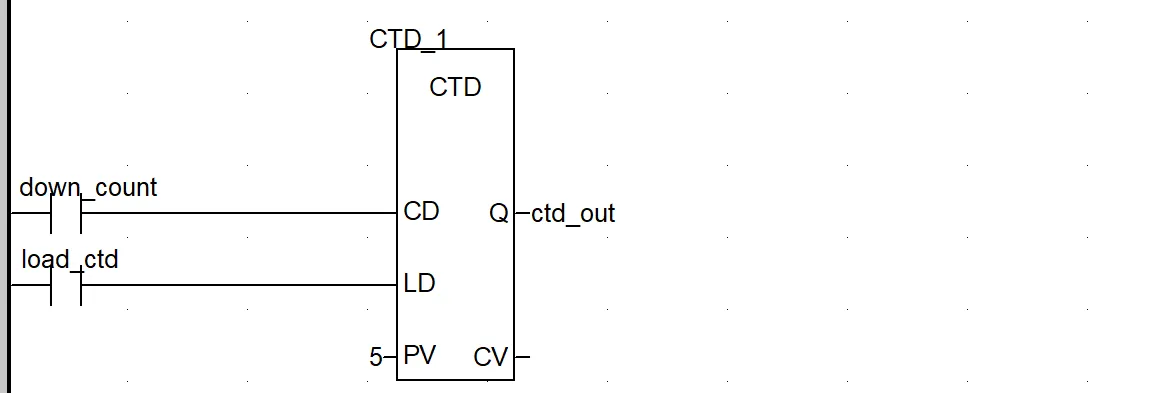

CTD Counter Operation Example

At the start, the load input (LD) is HIGH (TRUE), which loads the preset value (PV = 5) into the counter’s current value (CV). This means the counter starts with CV = 5 before any counting begins.

The count down input (CD) acts as the trigger to decrement the counter. Each time CD transitions from FALSE to TRUE, the counter decreases its current value by 1.

The current value (CV) shows the actual count at any given moment, decreasing step by step from 5 → 4 → 3 → … → 0. When the CV reaches 0, the output (Q) becomes TRUE, which can be used to trigger an action, such as stopping a conveyor or signaling the end of a batch.

In this example, the preset value (PV) is set to 5, so the counter counts down from 5 to 0 as CD pulses occur.

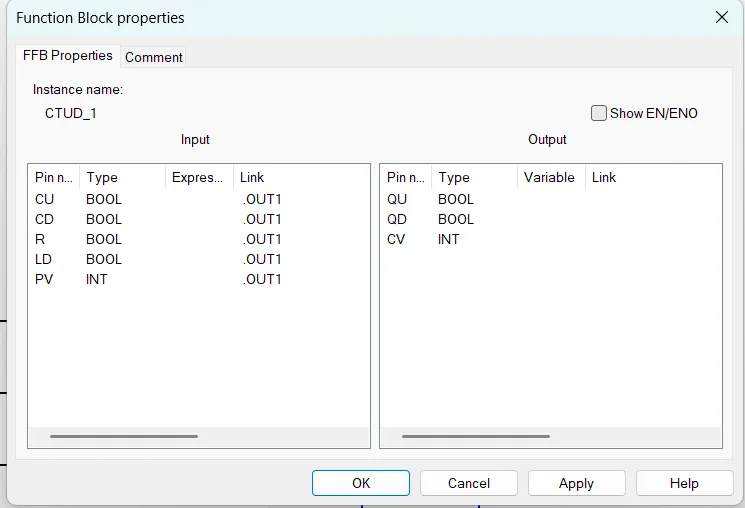

CTUD Counter in Schneider PLC

The CTUD (Count Up/Down) counter in Schneider PLC allows counting in both directions. It increments the counter when the Up input (CU) is activated and decrements when the Down input (CD) is activated. This is useful in applications such as reversible conveyors, position tracking, or any process that requires bi-directional counting.

Input Parameters:

- CU (BOOL): Up counter trigger input that increments the counter on TRUE.

- CD (BOOL): Down counter trigger input that decrements the counter on TRUE.

- R (BOOL): Reset input that resets the counter to zero when TRUE.

- LD (BOOL): Load input that loads the preset value (PV) into the counter when TRUE.

- PV: Preset value.

When CTUD: INT

When CTUD_***: INT, DINT, UINT, UDINT

Output Parameters:

- QU (BOOL): Output that indicates the counter has reached the preset value in the Up direction.

- QD (BOOL): Output that indicates the counter has reached the preset value in the Down direction.

- CV: Current value of the counter.

When CTUD: INT

When CTUD_***: INT, DINT, UINT, UDINT

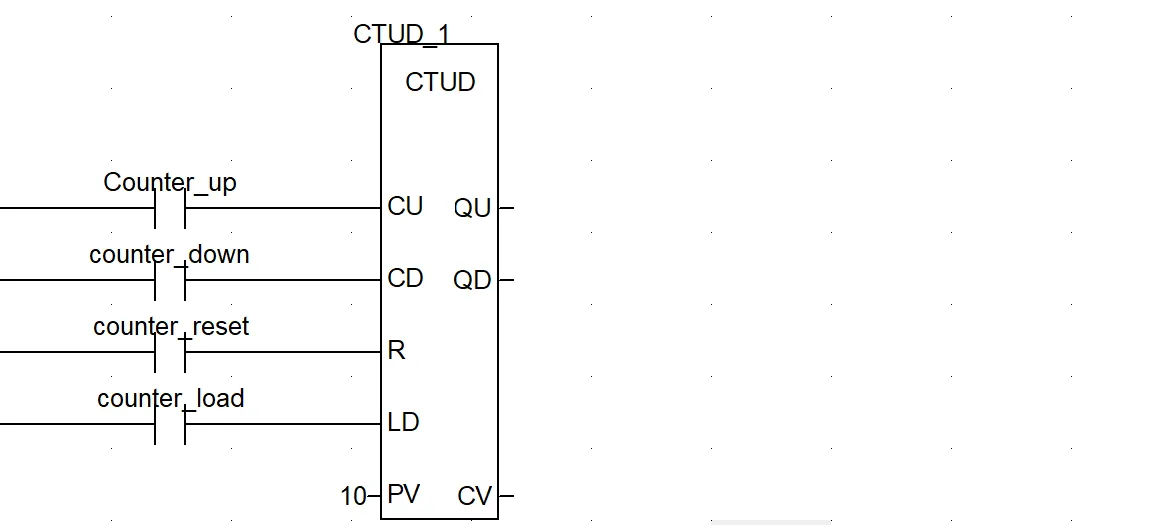

CTUD Counter Example with Reset

The CTUD (Count Up/Down) counter counts in both directions depending on the inputs. The CU input increments the current value (CV), while the CD input decrements CV. The preset value (PV) defines the maximum count for the Up direction.

In this example, PV is set to 8. Each time CU transitions from FALSE to TRUE, CV increases by 1. Each time CD transitions from FALSE to TRUE, CV decreases by 1.

The counter has separate outputs:

- QU: Becomes TRUE when CV reaches PV in the Up direction.

- QD: Becomes TRUE when CV reaches 0 in the Down direction.

The Reset input (counter_reset) clears the counter when activated. Activating reset sets CV to 0 and both QU and QD outputs become FALSE, allowing the counter to start a new counting cycle.

This functionality is useful in applications like reversible conveyors, bidirectional process monitoring, or any system requiring flexible counting with the ability to restart the count.

Steps to Enable or Disable EN/ENO

EN and ENO can be configured as additional parameters for function blocks.

- Double-click on the timer block to open its properties window.

- In the function block properties, look for the option labeled EN/ENO in the block settings.

- Check the box to enable EN/ENO, or uncheck it to disable EN/ENO.

- Click OK to save changes and close the properties window.

Disabling EN/ENO is useful when you want the timer to execute unconditionally, without being controlled by an enable input. This can simplify logic in certain automation scenarios.