How to Create Function Blocks Using SCL and Implement FBD Logic in Siemens TIA Portal

Published on Jun16, 2025 | Category: Function blocksShare this Page:

Function Blocks (FB) in Siemens TIA Portal are reusable code structures that permanently store their input, output, and in-out parameters in associated instance data blocks (DBs). This memory-retaining behavior allows Function Blocks to preserve values across scan cycles, making them ideal for controlling motors, monitoring sensors, handling timers, or managing process states.

Function Blocks can also use temporary variables, which exist only during a single program cycle and are not saved in the instance DB. These are useful for intermediate calculations and logic that doesn't require persistent storage.

Function Blocks are different from Functions (FC), as Functions do not retain state between calls. This makes FBs more suitable for logic where historical data or ongoing states need to be tracked.

In Siemens TIA Portal, you can create your own Function Blocks using any supported PLC programming language, such as Ladder Diagram (LAD), Function Block Diagram (FBD), or Structured Control Language (SCL). While the internal logic of the FB can be written in your preferred language, the block itself serves as a reusable container of logic that can be instantiated multiple times with different data.

In this article, we focus on how to create a Function Block in Siemens TIA Portal and implement its internal logic using Structured Control Language (SCL). SCL is a high-level text-based language, ideal for writing efficient, readable, and scalable PLC logic, especially when dealing with complex conditions, loops, or mathematical operations.

Applications of Function Blocks in Siemens TIA Portal

Function Blocks (FBs) are essential for implementing reusable and modular code in Siemens TIA Portal. They contain subroutines and logic that are executed every time the block is called by another code block, such as an organization block (OB) or another FB. One of the key advantages of Function Blocks is that they can be called multiple times at different locations within a program, each time using a unique instance data block. This allows the same logic to be applied across multiple devices or processes — such as motors, sensors, or valves — without duplicating code. FBs simplify the development and maintenance of large automation systems by encapsulating frequently recurring logic into structured and testable modules. They are especially useful in applications involving:

- Motor start/stop and protection logic

- Analog value scaling and signal conditioning

- PID control and temperature regulation

- Sequential process steps or state machines

- Communication routines (e.g., MODBUS, PROFIBUS)

- Machine safety monitoring and diagnostics

By using Function Blocks with Structured Control Language (SCL), you gain even more control and flexibility in expressing complex algorithms, loops, and conditional logic, while maintaining code clarity and reuse. This makes FBs a powerful tool for scalable, efficient, and professional-grade PLC programming in industrial automation projects.

Types of Function Blocks in Siemens TIA Portal

A Function Block (FB) is a reusable block of code that stores its data using an instance data block (DB). Unlike Functions (FC), Function Blocks can remember values from one cycle to the next, making them ideal for tasks like motor control, timers, and counters.

There are three main types of Function Block usage in TIA Portal:

- Single Instance: The FB is called with its own dedicated instance data block. All variables are stored in this unique DB. This is useful when you need the FB for one device or process.

- Multi-Instance: Multiple FBs are used inside a parent FB without creating separate DBs for each. Instead, the parent FB’s DB stores all internal data. This saves memory and keeps code organized.

- Parameter Instance: In this type, the FB instance is passed as an in/out parameter to another block at runtime. It allows flexible instantiation without fixed memory during program creation.

Each type helps structure your program based on memory needs, reusability, and system complexity.

How to Create Function Blocks Using SCL in Siemens TIA Portal

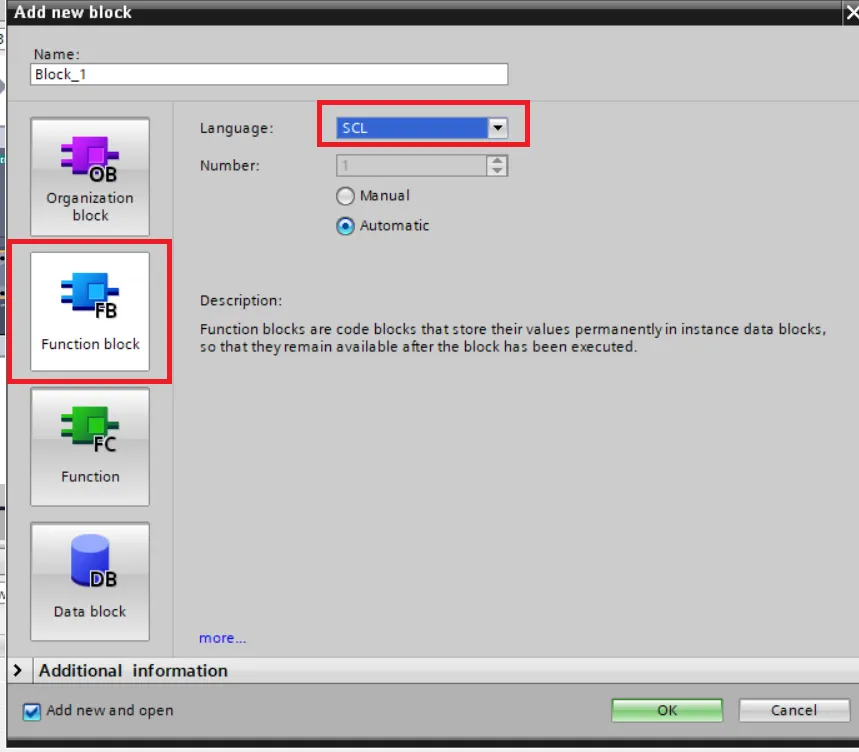

To create a Function Block (FB) using Structured Control Language (SCL) in Siemens TIA Portal, follow these steps:

- Open TIA Portal and create or configure your device (PLC) based on project requirements.

- In the Project Tree, navigate to Program blocks.

- Right-click on Program blocks and select Add new block.

- In the dialog box that appears, choose:

- Block type: Function Block (FB)

- Programming language: SCL (Structured Control Language)

- Enter a suitable name for your block (e.g., MotorControl_FB) and click OK.

This will create a new SCL-based Function Block where you can write your control logic using simple, readable high-level code.

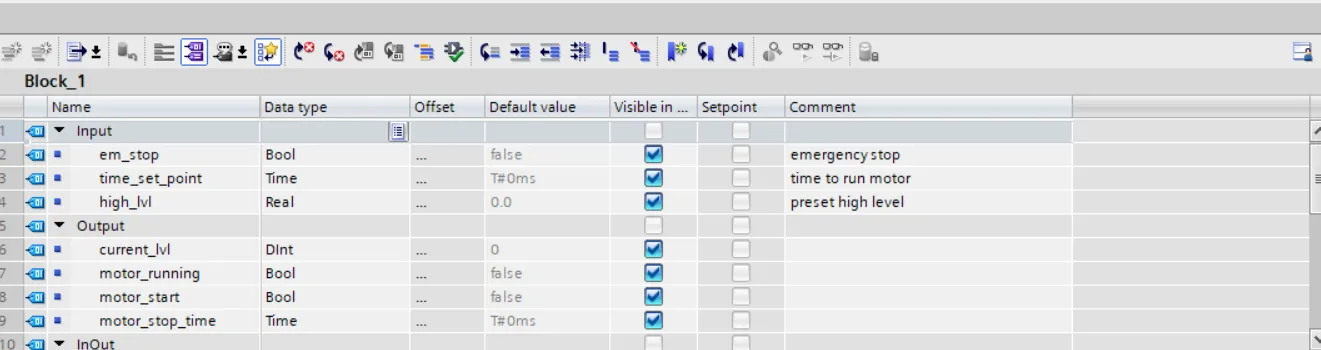

Define Parameters for Functional Blocks

In this example, we create a simple Function Block (FB) using SCL, which includes both input and output parameters. Defining parameters is an essential part of creating reusable logic blocks. Inputs are used to receive data from outside the FB, and outputs are used to send results back to the main program.

Input Parameters

Input parameters are used to provide values or control signals to the function block. In this example, we define the following input tags:

- em_stop: A Boolean input to represent the emergency stop condition. If this is TRUE, the motor should not start.

- time_set_point: A TIME data type that defines how long the motor should run when started.

- high_lvl: A REAL data type input representing the current level from an analog sensor after scaling.

Output Parameters

Output parameters are used to provide the results or status back to the main program. In this function block, the following outputs are defined:

- current_lvl: A DINT value calculated from the motor's runtime duration.

- motor_running: A Boolean value that shows whether the motor is currently running.

- motor_stop: A Boolean output used to signal when the motor should stop.

- motor_stop_time: A TIME output that holds the actual elapsed runtime of the motor.

These parameters make the function block modular and reusable, so you can use it in multiple places without writing the same logic again.

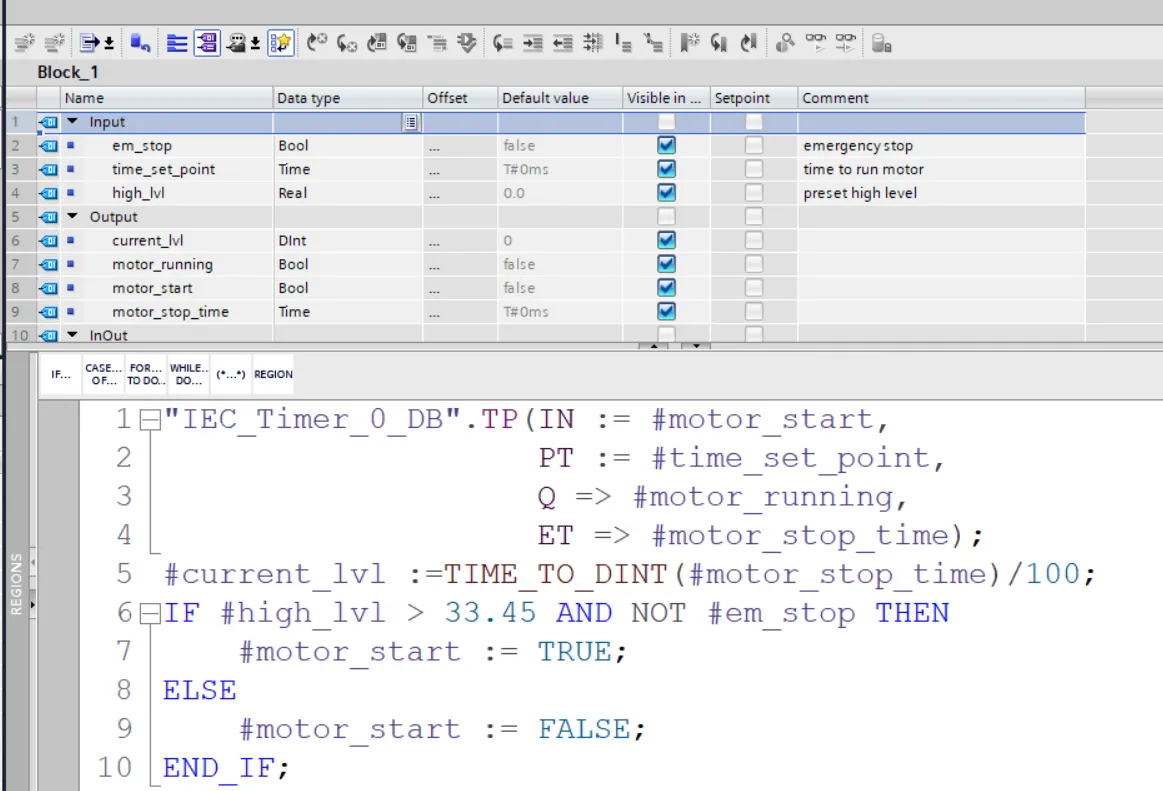

Simple Example of Function Block in SCL

This is a basic example of using a Function Block (FB) in Structured Control Language (SCL) to control a motor using a timer and a level condition.

In this logic, when the high level value becomes greater than 33.45 and the emergency stop (em_stop) is not activated, the motor is started for a fixed time using a Pulse Timer (TP).

The TP timer keeps the output Q active for the duration specified in PT (preset time). The elapsed time is captured in ET. This elapsed time is converted to a numeric value and stored in current_lvl to monitor how long the motor has run.

Once the level goes below the limit or the emergency stop is pressed, the motor will stop on the next scan cycle.

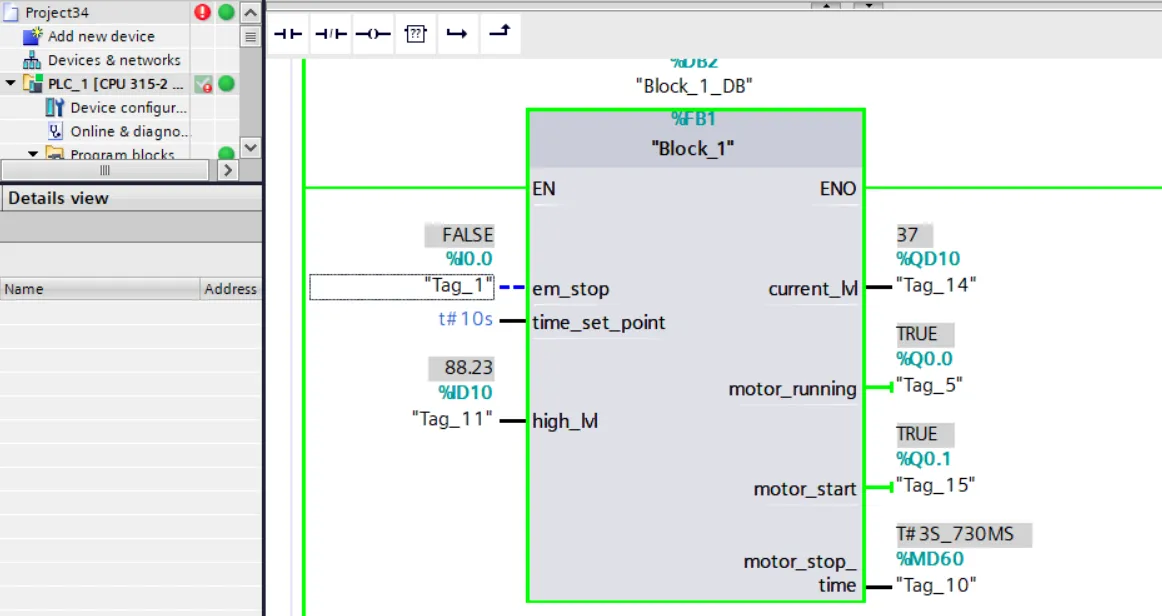

Call Function Block in Main Program (OB1)

Once you create your Function Block (FB), compile it, and open the main program block — usually called OB1. From here, you can call the FB and use it in your main logic.

Ways to Call a Function Block

1. Single Instance: The function block gets its own separate data block to store values. This is best for simple and reusable tasks.

2. Multi-Instance: The FB is used inside another FB and shares the same instance data block. It’s useful when you want to organize logic and save memory.

How to Insert a Function Block in OB1

- Go to the project tree and drag the function block into OB1.

- A dialog will appear asking how to insert the block:

- Single Instance: Enter a name for the new data block.

- Multi-Instance: Enter a tag name for referencing inside another FB.

- Parameter Instance: Use an InOut parameter to pass the instance at runtime.

- Click "OK" to insert the function block.

Set Parameters

- Inputs use := to assign values.

- Outputs use => to get values back.

- Use constants, variables, or expressions as values.

- The order of parameters doesn't matter.

- Use the TAB key to quickly move through fields.

This makes the FB fully active in your main program, ready to run its logic based on the inputs you provide.

Check, Compile, and Download Program to PLC

After writing your Function Block and main logic in SCL, the next important step is to check your program for errors and download it to the PLC. This ensures that your logic is working correctly and ready for execution in the real environment.

First, click on the "Compile" button in TIA Portal to check for syntax or configuration errors. Make sure all blocks, tags, and instances are correctly assigned and there are no red error messages.

Before downloading the program to the actual PLC, it's highly recommended to test it using the built-in PLC simulator (PLCSIM). The simulator allows you to run the code in a virtual environment, monitor values, and verify your logic without needing physical hardware.

Once your logic works as expected in simulation, connect to the PLC device, set it to online mode, and download your program. Confirm all prompts, and ensure that your Function Blocks and OB1 are selected for transfer.

After downloading, switch the PLC to RUN mode. You can now monitor your Function Block execution in real-time and ensure the inputs and outputs respond as expected.